Pig iron is a basic intermediate product of smelting iron ore in a blast furnace, characterized by high carbon content and brittleness, making it unsuitable for direct use in manufacturing. Ductile iron, also known as nodular cast iron, undergoes a secondary treatment process where small amounts of magnesium or cerium are added, resulting in improved ductility, strength, and impact resistance. The microstructure differences between pig iron and ductile iron provide significant advantages for industrial applications requiring enhanced mechanical properties and durability.

Table of Comparison

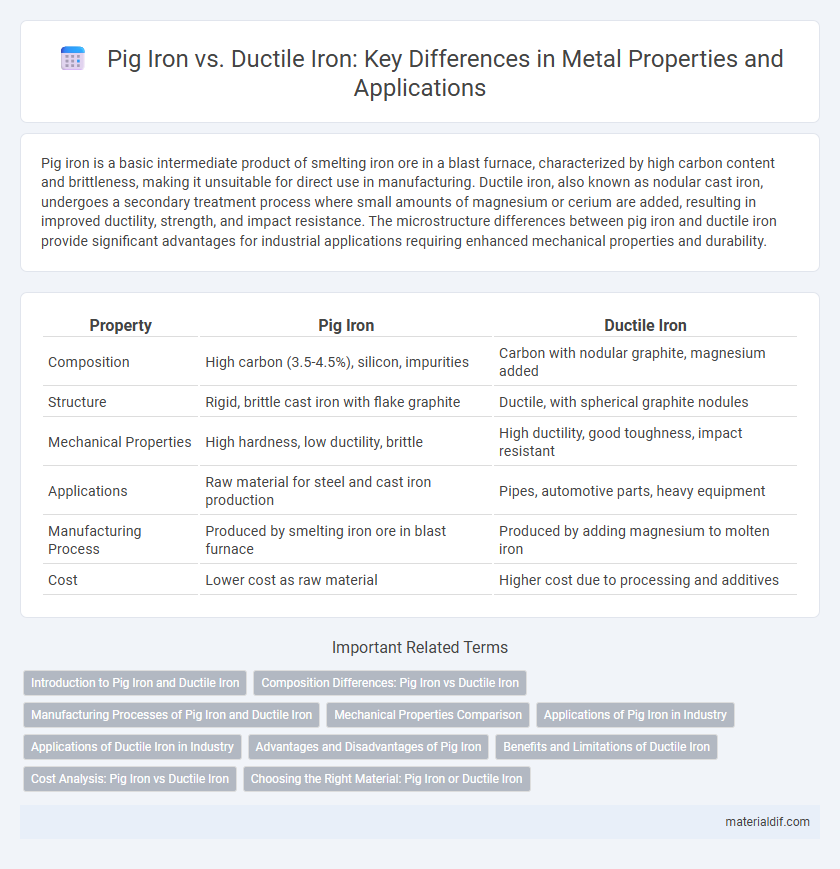

| Property | Pig Iron | Ductile Iron |

|---|---|---|

| Composition | High carbon (3.5-4.5%), silicon, impurities | Carbon with nodular graphite, magnesium added |

| Structure | Rigid, brittle cast iron with flake graphite | Ductile, with spherical graphite nodules |

| Mechanical Properties | High hardness, low ductility, brittle | High ductility, good toughness, impact resistant |

| Applications | Raw material for steel and cast iron production | Pipes, automotive parts, heavy equipment |

| Manufacturing Process | Produced by smelting iron ore in blast furnace | Produced by adding magnesium to molten iron |

| Cost | Lower cost as raw material | Higher cost due to processing and additives |

Introduction to Pig Iron and Ductile Iron

Pig iron, a high-carbon intermediate product of smelting iron ore in a blast furnace, serves as a primary raw material for steelmaking and cast iron production due to its brittle nature and high carbon content. Ductile iron, also known as nodular or spheroidal graphite iron, is a type of cast iron characterized by its spherical graphite inclusions, which enhance its tensile strength, ductility, and impact resistance. The transformation from pig iron to ductile iron involves alloying and controlled cooling processes that optimize mechanical properties for industrial applications.

Composition Differences: Pig Iron vs Ductile Iron

Pig iron primarily contains 3-4.5% carbon and high levels of silicon, manganese, and sulfur, resulting in a brittle and hard material. Ductile iron differs with a lower carbon content, typically around 3%, and includes magnesium or cerium as nodulizing agents that transform graphite into spherical shapes, enhancing ductility. The distinct composition variations in elements and microstructure directly influence their mechanical properties and applications in metalworking.

Manufacturing Processes of Pig Iron and Ductile Iron

Pig iron is produced by smelting iron ore in a blast furnace using coke and limestone, resulting in a high-carbon intermediate product. Ductile iron is manufactured by adding nodulizing agents such as magnesium or cerium to molten pig iron, which modifies the graphite structure into spheroids, enhancing ductility and strength. The controlled cooling and inoculation processes during ductile iron casting further optimize its mechanical properties for industrial applications.

Mechanical Properties Comparison

Pig iron exhibits high carbon content, resulting in brittleness and low tensile strength, typically around 200 MPa, making it less suitable for structural applications. Ductile iron, enhanced by nodular graphite inclusions, offers superior mechanical properties including tensile strength ranging from 400 to 700 MPa and excellent elongation of 10-20%, providing enhanced toughness and impact resistance. The improved ductility and fatigue strength of ductile iron make it a preferred material over pig iron for components subjected to dynamic stresses.

Applications of Pig Iron in Industry

Pig iron is primarily used as a raw material in the steelmaking industry, where it serves as a key intermediary for producing cast iron and steel products. Its high carbon content makes it ideal for remelting in blast furnaces and electric arc furnaces to create various grades of steel and castings. Industries such as construction, automotive manufacturing, and machinery heavily rely on pig iron for producing durable components and structural materials.

Applications of Ductile Iron in Industry

Ductile iron is extensively used in industries such as automotive manufacturing for engine blocks, crankshafts, and suspension components due to its superior strength and machinability compared to pig iron. Its high ductility and resistance to impact make it ideal for pipeline systems, valves, and heavy-duty gears in the energy and water treatment sectors. The material's excellent fatigue resistance and corrosion properties also contribute to its prevalence in construction and agricultural machinery applications.

Advantages and Disadvantages of Pig Iron

Pig iron, characterized by its high carbon content and brittle nature, offers advantages such as cost-effectiveness and ease of production from raw iron ore through blast furnace processes. However, its disadvantages include limited mechanical strength, poor ductility, and susceptibility to cracking, making it unsuitable for applications requiring durability and flexibility. Unlike ductile iron, pig iron requires further refining and alloying to improve its structural properties and usability in industrial manufacturing.

Benefits and Limitations of Ductile Iron

Ductile iron offers superior tensile strength and enhanced ductility compared to pig iron, making it ideal for components requiring high durability and impact resistance. Its improved elasticity allows for better shock absorption, reducing the risk of fractures in structural applications. However, ductile iron's production cost is higher due to additional alloying and treatment processes, and it may require more precise control of casting parameters to achieve desired mechanical properties.

Cost Analysis: Pig Iron vs Ductile Iron

Pig iron generally costs less than ductile iron due to its lower processing requirements and simpler production methods. Ductile iron, with added nodularizing agents and enhanced mechanical properties, commands higher manufacturing costs but offers better performance and durability. Analyzing cost-effectiveness depends on balancing initial material expense against long-term benefits such as strength, machinability, and lifespan.

Choosing the Right Material: Pig Iron or Ductile Iron

Pig iron, a high-carbon intermediate product of smelting iron ore, offers excellent hardness and wear resistance but lacks ductility and impact strength, making it suitable for casting applications where brittleness is acceptable. Ductile iron, characterized by spherical graphite inclusions, combines superior strength, ductility, and fatigue resistance, ideal for components subjected to dynamic loads and mechanical stresses. Selecting between pig iron and ductile iron depends on the required mechanical properties, application environment, and performance criteria to ensure optimal material performance and longevity.

Pig Iron vs Ductile Iron Infographic

materialdif.com

materialdif.com