Anodized metal features a durable oxide layer formed through an electrochemical process, enhancing corrosion resistance and surface hardness while preserving the metal's metallic appearance. Powder-coated metal involves applying a dry powder that is cured under heat to form a thick, protective, and colorful finish, offering excellent impact resistance and a wide range of design options. Choosing between anodized and powder-coated finishes depends on desired aesthetics, environmental durability, and specific application requirements.

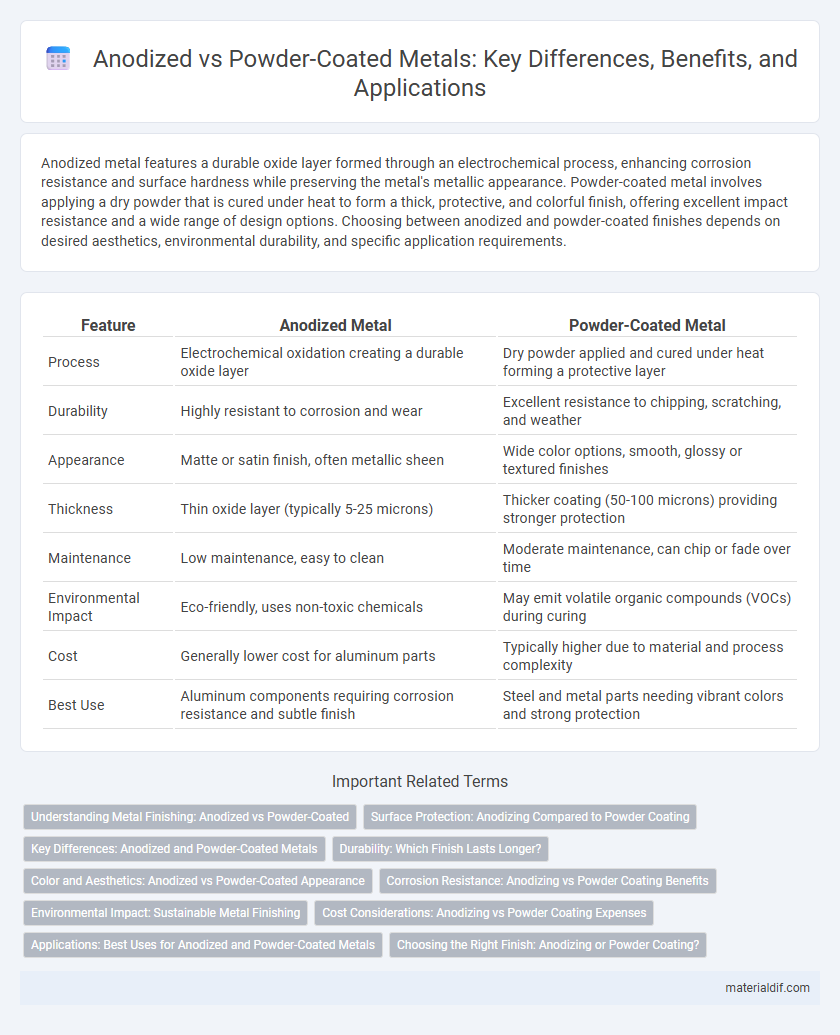

Table of Comparison

| Feature | Anodized Metal | Powder-Coated Metal |

|---|---|---|

| Process | Electrochemical oxidation creating a durable oxide layer | Dry powder applied and cured under heat forming a protective layer |

| Durability | Highly resistant to corrosion and wear | Excellent resistance to chipping, scratching, and weather |

| Appearance | Matte or satin finish, often metallic sheen | Wide color options, smooth, glossy or textured finishes |

| Thickness | Thin oxide layer (typically 5-25 microns) | Thicker coating (50-100 microns) providing stronger protection |

| Maintenance | Low maintenance, easy to clean | Moderate maintenance, can chip or fade over time |

| Environmental Impact | Eco-friendly, uses non-toxic chemicals | May emit volatile organic compounds (VOCs) during curing |

| Cost | Generally lower cost for aluminum parts | Typically higher due to material and process complexity |

| Best Use | Aluminum components requiring corrosion resistance and subtle finish | Steel and metal parts needing vibrant colors and strong protection |

Understanding Metal Finishing: Anodized vs Powder-Coated

Anodized metal offers a durable, corrosion-resistant surface achieved through an electrochemical process that thickens the natural oxide layer, enhancing wear resistance and maintaining the metal's original texture. Powder-coated finishes provide a thicker, more uniform protective layer through the application of a dry powder cured under heat, resulting in superior color variety and impact resistance ideal for outdoor and high-traffic environments. Choosing between anodized and powder-coated metal depends on specific requirements for aesthetic appeal, environmental exposure, and mechanical durability.

Surface Protection: Anodizing Compared to Powder Coating

Anodizing creates a durable, corrosion-resistant oxide layer on aluminum surfaces, enhancing wear resistance and preventing scratches, while powder coating applies a thick, protective polymer finish that guards against chipping, fading, and moisture. Anodized surfaces maintain metal's natural texture and conductivity, beneficial for electrical applications, whereas powder coating offers customizable colors and a uniform appearance for aesthetic versatility. Both methods extend metal longevity, but anodizing excels in abrasion resistance and environmental durability, making it preferable for industrial use.

Key Differences: Anodized and Powder-Coated Metals

Anodized metals undergo an electrochemical process that thickens the natural oxide layer, enhancing corrosion resistance and surface hardness while maintaining a metallic appearance. Powder-coated metals feature a dry powder layer that is heat-cured to form a durable, colorful, and uniform finish, offering superior protection against scratches and UV rays. Anodizing is ideal for aluminum and provides a thin, integral coating, whereas powder coating suits various metals and produces a thicker, more versatile protective layer.

Durability: Which Finish Lasts Longer?

Anodized finishes enhance metal durability by creating a hard, corrosion-resistant oxide layer that withstands scratches and wear better than powder coating. Powder-coated surfaces rely on a thick polymer layer that resists chipping and UV damage but may degrade faster in harsh environments. For long-term durability, anodizing typically outperforms powder coating, especially on aluminum alloys exposed to outdoor elements.

Color and Aesthetics: Anodized vs Powder-Coated Appearance

Anodized metal features a clear, natural finish that enhances its metallic sheen and offers subtle, consistent color options linked to the metal's composition. Powder-coated surfaces provide a wider palette of vibrant colors with a matte or glossy finish, creating uniform coverage that can conceal surface imperfections. The choice between anodized and powder-coated finishes depends on desired color intensity, durability, and the specific aesthetic appeal for architectural or industrial applications.

Corrosion Resistance: Anodizing vs Powder Coating Benefits

Anodizing enhances corrosion resistance by creating a durable oxide layer on aluminum surfaces, which prevents rust and wear through a natural, integrated barrier. Powder coating provides a thicker, uniform protective finish that is highly resistant to moisture, chemicals, and UV exposure, ideal for harsh environmental conditions. Both methods improve metal longevity, but anodizing is often preferred for wear resistance and electrical insulation, while powder coating excels in color variety and impact durability.

Environmental Impact: Sustainable Metal Finishing

Anodized metal offers an environmentally sustainable finishing process by enhancing corrosion resistance while using non-toxic electrolytes, producing minimal hazardous waste. Powder-coated finishes utilize solvent-free powders that reduce volatile organic compound (VOC) emissions, contributing to lower air pollution during application. Both methods improve metal longevity, ultimately decreasing the need for frequent replacements and reducing resource consumption.

Cost Considerations: Anodizing vs Powder Coating Expenses

Anodizing typically incurs higher initial costs due to its complex electrochemical process, making it more expensive for intricate or large-scale metal parts. Powder coating offers a more cost-effective solution with lower material and application expenses, especially suitable for large production runs requiring durable finishes. Long-term maintenance costs favor anodizing because of its superior corrosion and wear resistance, potentially offsetting the higher upfront investment.

Applications: Best Uses for Anodized and Powder-Coated Metals

Anodized metal excels in applications requiring enhanced corrosion resistance and surface hardness, making it ideal for aerospace components, automotive parts, and architectural elements exposed to harsh environments. Powder-coated metal offers superior durability and color variety, often used in outdoor furniture, industrial equipment, and household appliances where impact resistance and aesthetic appeal are crucial. Both finishes provide long-lasting protection, but anodizing suits aluminum alloys better, while powder coating adapts to steel and diverse metals for versatile use.

Choosing the Right Finish: Anodizing or Powder Coating?

Anodizing enhances aluminum by creating a durable oxide layer that improves corrosion resistance and provides a natural metallic finish, ideal for outdoor or architectural applications. Powder coating offers a thick, colorful, and uniform protective layer that resists chipping, scratching, and fading, making it suitable for heavy-use items and industrial equipment. Selecting between anodized and powder-coated finishes depends on the desired durability, aesthetic, and environmental exposure of the metal product.

Anodized vs Powder-Coated Infographic

materialdif.com

materialdif.com