CNC machining offers precision and flexibility in producing metal parts with complex geometries through subtractive manufacturing, making it ideal for low to medium volume production. Metal injection molding (MIM) combines the design freedom of plastic injection molding with the strength of powdered metallurgy, enabling high-volume production of small, intricate metal components with minimal post-processing. Choosing between CNC machining and MIM depends on factors such as part complexity, production volume, and cost efficiency.

Table of Comparison

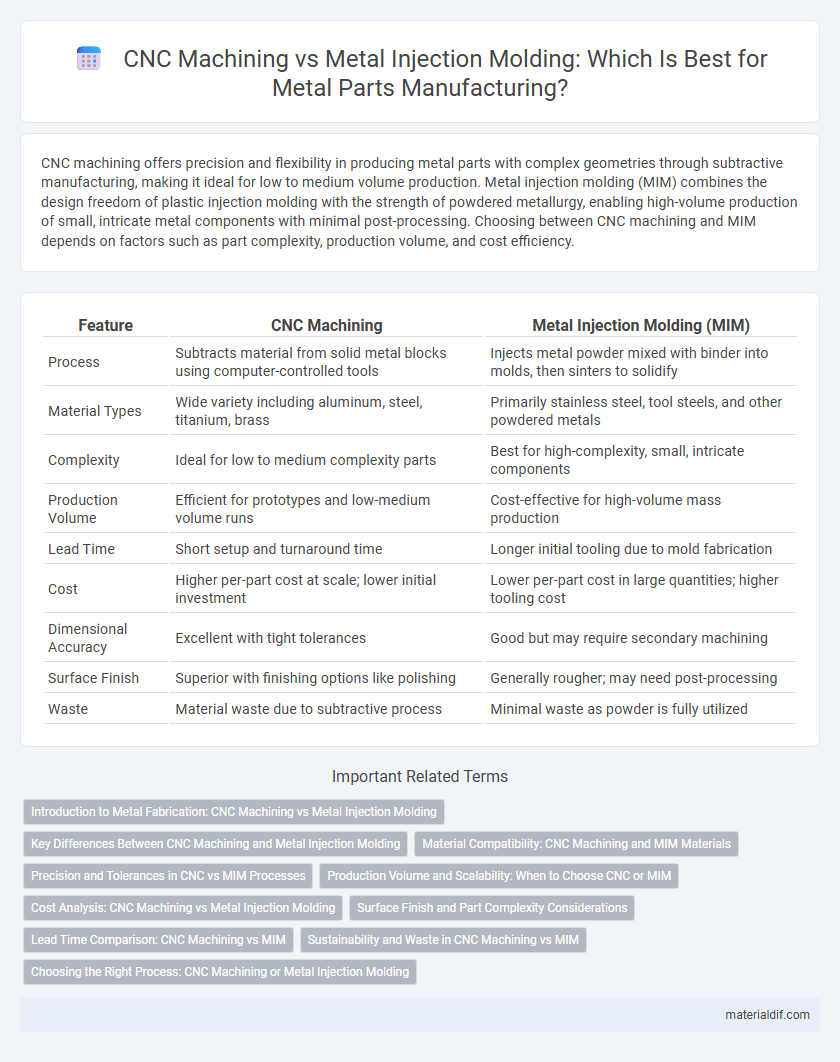

| Feature | CNC Machining | Metal Injection Molding (MIM) |

|---|---|---|

| Process | Subtracts material from solid metal blocks using computer-controlled tools | Injects metal powder mixed with binder into molds, then sinters to solidify |

| Material Types | Wide variety including aluminum, steel, titanium, brass | Primarily stainless steel, tool steels, and other powdered metals |

| Complexity | Ideal for low to medium complexity parts | Best for high-complexity, small, intricate components |

| Production Volume | Efficient for prototypes and low-medium volume runs | Cost-effective for high-volume mass production |

| Lead Time | Short setup and turnaround time | Longer initial tooling due to mold fabrication |

| Cost | Higher per-part cost at scale; lower initial investment | Lower per-part cost in large quantities; higher tooling cost |

| Dimensional Accuracy | Excellent with tight tolerances | Good but may require secondary machining |

| Surface Finish | Superior with finishing options like polishing | Generally rougher; may need post-processing |

| Waste | Material waste due to subtractive process | Minimal waste as powder is fully utilized |

Introduction to Metal Fabrication: CNC Machining vs Metal Injection Molding

CNC machining and metal injection molding (MIM) are essential metal fabrication techniques with distinct advantages. CNC machining provides high precision and flexibility for complex geometries in low to medium production volumes, while MIM excels in mass production of small, intricate metal parts with consistent quality. Selecting between CNC machining and MIM depends on factors such as part complexity, volume, material properties, and cost efficiency.

Key Differences Between CNC Machining and Metal Injection Molding

CNC machining involves subtractive manufacturing, precisely cutting metal from solid blocks, while metal injection molding (MIM) combines powdered metal and binder materials to form complex shapes through injection and sintering. CNC machining offers superior dimensional accuracy and surface finish for low to medium-volume production, whereas MIM excels in producing high volumes of intricate parts with minimal post-processing. Material waste is higher in CNC machining, whereas MIM allows near-net-shape production, reducing raw material loss and enabling cost efficiency in mass manufacturing.

Material Compatibility: CNC Machining and MIM Materials

CNC machining supports a wide range of metals including aluminum, steel, titanium, and brass, offering precise control over hard and dense materials. Metal Injection Molding (MIM) is particularly compatible with stainless steel, tool steels, and high-performance alloys like Inconel, enabling complex geometries in small, high-volume parts. Material compatibility impacts mechanical properties, production cost, and application suitability in aerospace, automotive, and medical industries.

Precision and Tolerances in CNC vs MIM Processes

CNC machining offers superior precision with tolerances typically as tight as +-0.005 mm, making it ideal for complex metal parts requiring high dimensional accuracy. Metal Injection Molding (MIM) generally achieves tolerances around +-0.02 mm, suitable for mass production of small, intricate components but with less precision compared to CNC. The choice between CNC and MIM depends on the required tolerance levels and production volume, with CNC excelling in precision and MIM providing cost-effective scalability.

Production Volume and Scalability: When to Choose CNC or MIM

CNC machining excels in low to medium production volumes, offering precision and flexibility for custom or complex metal parts without the need for expensive tooling. Metal Injection Molding (MIM) is ideal for high-volume production runs, providing cost-effective scalability and consistent quality for small, intricate metal components. Choose CNC for prototypes or limited runs, while MIM is best suited for mass production demanding efficiency and repeatability.

Cost Analysis: CNC Machining vs Metal Injection Molding

CNC machining typically incurs higher per-part costs due to longer cycle times and increased material waste, especially for complex or low-volume metal components, whereas metal injection molding (MIM) offers cost advantages in mass production by enabling high-volume output and minimal material scrap. Initial tooling and setup costs for MIM are significantly higher, often making it less economical for small production runs compared to CNC machining, which requires minimal tooling investment. The cost efficiency of CNC machining improves with design simplicity and smaller batch sizes, while MIM becomes more cost-effective as production scales exceed several thousand units.

Surface Finish and Part Complexity Considerations

CNC machining delivers superior surface finish with tight tolerances, ideal for intricate metal parts requiring smooth, precise edges. Metal Injection Molding (MIM) excels at producing highly complex geometries and fine details in bulk but may require secondary finishing to achieve comparable surface quality. Surface finish preferences and part complexity dictate the choice between CNC's precision and MIM's efficiency in manufacturing metal components.

Lead Time Comparison: CNC Machining vs MIM

CNC machining typically offers shorter lead times for low to medium production volumes, as it involves direct material removal without the need for tooling setup. Metal Injection Molding (MIM) requires longer lead times upfront due to mold design and fabrication, but becomes more time-efficient for high-volume production runs. Choosing between CNC machining and MIM depends on part complexity, order size, and urgency in metal component manufacturing.

Sustainability and Waste in CNC Machining vs MIM

CNC machining generates significant metal waste due to the subtractive process, leading to lower material efficiency compared to Metal Injection Molding (MIM), which produces near-net-shape parts with minimal scrap. MIM uses fine metal powders sintered into parts, drastically reducing excess material and energy consumption throughout production. This efficiency makes MIM a more sustainable option, particularly for high-volume manufacturing where waste reduction and resource conservation are critical.

Choosing the Right Process: CNC Machining or Metal Injection Molding

Selecting between CNC machining and metal injection molding depends on factors such as production volume, part complexity, and material requirements. CNC machining offers precision and flexibility for low to medium production runs and complex geometries, while metal injection molding excels in high-volume manufacturing with intricate, small metal parts at lower per-unit costs. Evaluating these parameters ensures the right manufacturing process aligns with project specifications and cost efficiency.

CNC Machining vs Metal Injection Molding Infographic

materialdif.com

materialdif.com