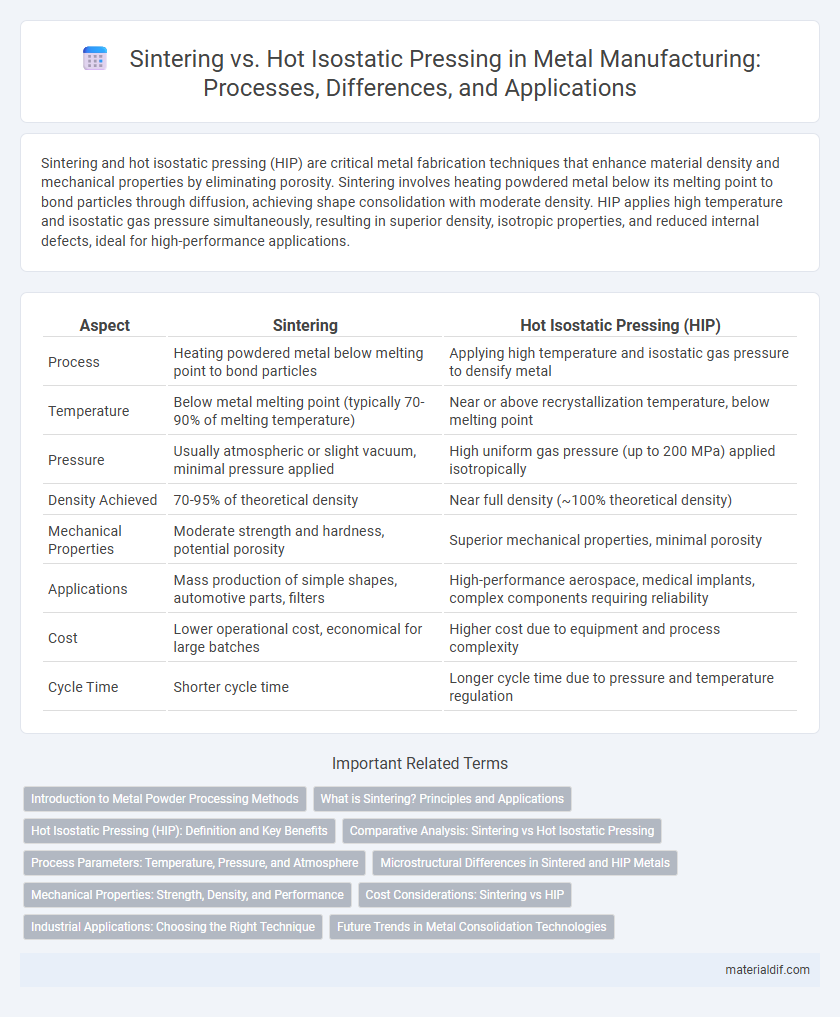

Sintering and hot isostatic pressing (HIP) are critical metal fabrication techniques that enhance material density and mechanical properties by eliminating porosity. Sintering involves heating powdered metal below its melting point to bond particles through diffusion, achieving shape consolidation with moderate density. HIP applies high temperature and isostatic gas pressure simultaneously, resulting in superior density, isotropic properties, and reduced internal defects, ideal for high-performance applications.

Table of Comparison

| Aspect | Sintering | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Process | Heating powdered metal below melting point to bond particles | Applying high temperature and isostatic gas pressure to densify metal |

| Temperature | Below metal melting point (typically 70-90% of melting temperature) | Near or above recrystallization temperature, below melting point |

| Pressure | Usually atmospheric or slight vacuum, minimal pressure applied | High uniform gas pressure (up to 200 MPa) applied isotropically |

| Density Achieved | 70-95% of theoretical density | Near full density (~100% theoretical density) |

| Mechanical Properties | Moderate strength and hardness, potential porosity | Superior mechanical properties, minimal porosity |

| Applications | Mass production of simple shapes, automotive parts, filters | High-performance aerospace, medical implants, complex components requiring reliability |

| Cost | Lower operational cost, economical for large batches | Higher cost due to equipment and process complexity |

| Cycle Time | Shorter cycle time | Longer cycle time due to pressure and temperature regulation |

Introduction to Metal Powder Processing Methods

Metal powder processing methods such as sintering and hot isostatic pressing (HIP) are essential in manufacturing high-performance metal components. Sintering involves heating compacted metal powders below their melting point to bond particles through diffusion, resulting in porous structures with controlled density. In contrast, HIP applies high temperature and isostatic gas pressure simultaneously, producing fully dense, defect-free parts with superior mechanical properties suitable for critical aerospace and medical applications.

What is Sintering? Principles and Applications

Sintering is a metal powder processing technique that uses controlled heat below the melting point to bond particles into a solid mass, enhancing material density and mechanical properties. This process relies on atomic diffusion principles to fuse powders, eliminating porosity and increasing strength, commonly in manufacturing automotive parts, aerospace components, and cutting tools. Its applications include producing complex shapes with high precision and improved wear resistance, making sintering essential in advanced metal fabrication industries.

Hot Isostatic Pressing (HIP): Definition and Key Benefits

Hot Isostatic Pressing (HIP) is a manufacturing process that applies high pressure and temperature uniformly around a metal workpiece to eliminate porosity and enhance density. This technique improves mechanical properties such as strength, toughness, and fatigue resistance by creating a fully dense microstructure. HIP is widely used in aerospace, automotive, and medical industries for producing high-performance metal components with superior structural integrity.

Comparative Analysis: Sintering vs Hot Isostatic Pressing

Sintering involves compacting and forming metal powders through heat below their melting point, emphasizing cost-effective production with moderate density and mechanical properties, while Hot Isostatic Pressing (HIP) applies high pressure and temperature uniformly to eliminate porosity and enhance material density, resulting in superior strength and fatigue resistance. HIP offers improved microstructural uniformity and dimensional precision compared to sintering, making it ideal for critical aerospace and medical components requiring exceptional mechanical performance. The trade-off includes higher operational costs and longer cycle times for HIP, whereas sintering remains favorable for large-volume manufacturing with less stringent mechanical requirements.

Process Parameters: Temperature, Pressure, and Atmosphere

Sintering operates at temperatures typically between 70% to 90% of the metal's melting point, applying moderate pressure or sometimes none, within controlled atmospheres such as vacuum, inert gas, or reducing environments to prevent oxidation. Hot Isostatic Pressing (HIP) subjects metals to higher pressures, often exceeding 100 MPa, combined with temperatures close to or above 90% of the melting point, under an inert gas atmosphere like argon to ensure uniform densification and elimination of internal porosity. Control over temperature ramp rates, pressure application, and atmosphere composition is critical for optimizing microstructure, mechanical properties, and dimensional stability in both sintering and HIP processes.

Microstructural Differences in Sintered and HIP Metals

Sintering results in a microstructure characterized by partial grain bonding and residual porosity, often leading to anisotropic mechanical properties in metals. Hot Isostatic Pressing (HIP) produces a fully dense microstructure with reduced porosity and more uniform grain structure due to isostatic pressure applied at elevated temperatures. The enhanced density and homogeneity in HIP metals improve strength, fatigue resistance, and corrosion performance compared to conventionally sintered counterparts.

Mechanical Properties: Strength, Density, and Performance

Sintering typically achieves moderate density and strength by heating metal powders below their melting points, resulting in porous microstructures that can limit mechanical performance. Hot Isostatic Pressing (HIP) applies high temperature and isostatic gas pressure uniformly, producing near-full density metals with superior strength and enhanced fatigue resistance. The improved densification in HIP leads to fewer defects and higher mechanical integrity, making it preferable for critical structural applications demanding exceptional performance.

Cost Considerations: Sintering vs HIP

Sintering generally offers lower upfront costs and simpler equipment requirements compared to Hot Isostatic Pressing (HIP), making it more economical for large-volume production of metal parts with moderate performance demands. HIP involves higher capital investment and operational expenses due to the need for high-pressure vessels and precise gas environments, but it significantly enhances material density and mechanical properties, reducing long-term costs related to failed components or material waste. Cost-efficiency evaluation between sintering and HIP depends on the application's performance requirements, production volume, and acceptable tolerance levels in metal parts.

Industrial Applications: Choosing the Right Technique

Sintering enables cost-effective mass production of complex metal components with controlled porosity, ideal for automotive and aerospace parts requiring lightweight durability. Hot Isostatic Pressing (HIP) offers superior material density and mechanical properties, making it crucial in critical applications such as gas turbine blades and medical implants where structural integrity is paramount. Selecting between sintering and HIP depends on the balance between production volume, mechanical performance requirements, and cost constraints in industrial settings.

Future Trends in Metal Consolidation Technologies

Future trends in metal consolidation technologies emphasize the integration of sintering and hot isostatic pressing (HIP) with advanced additive manufacturing techniques to enhance density and mechanical properties. Innovations in hybrid processes combining sintering's cost-effectiveness with HIP's capability to eliminate internal porosity are driving improvements in aerospace and automotive component performance. Research is also focused on using real-time monitoring and AI-driven optimization to precisely control microstructure evolution during metal consolidation, reducing defects and increasing production efficiency.

Sintering vs Hot Isostatic Pressing Infographic

materialdif.com

materialdif.com