Sheet metal is thinner and more flexible, making it ideal for applications requiring bending and shaping, such as automotive panels and HVAC ductwork. Plate metal is thicker and stronger, suited for heavy structural components like bridges and industrial machinery that need increased durability. The distinction between sheet and plate metal lies primarily in their thickness, with sheet metal typically measuring less than 6mm and plate metal exceeding that thickness.

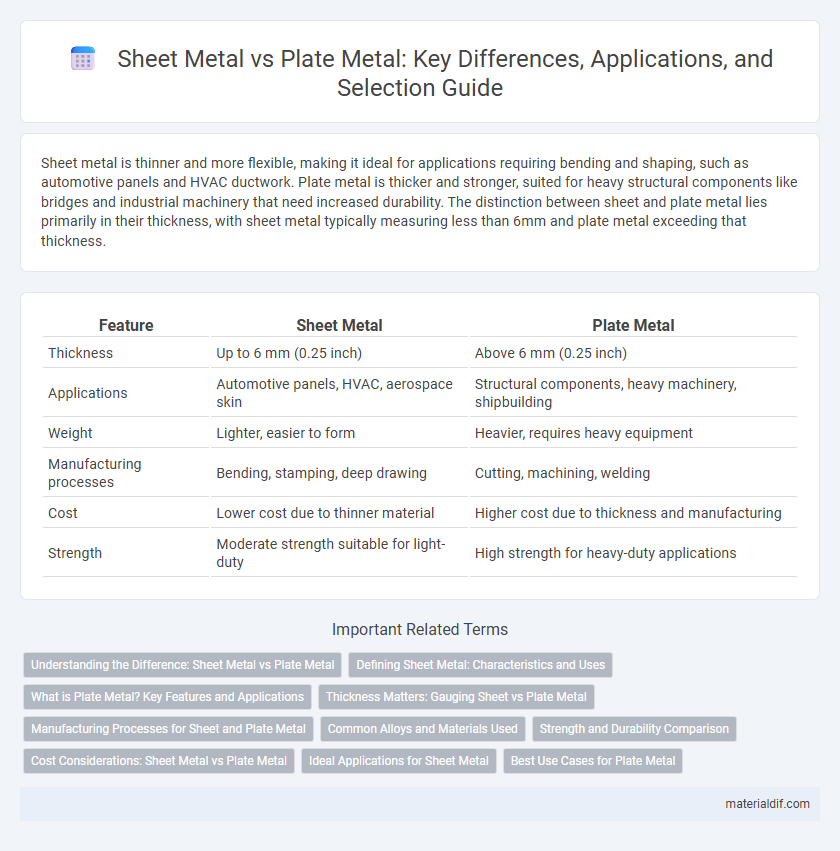

Table of Comparison

| Feature | Sheet Metal | Plate Metal |

|---|---|---|

| Thickness | Up to 6 mm (0.25 inch) | Above 6 mm (0.25 inch) |

| Applications | Automotive panels, HVAC, aerospace skin | Structural components, heavy machinery, shipbuilding |

| Weight | Lighter, easier to form | Heavier, requires heavy equipment |

| Manufacturing processes | Bending, stamping, deep drawing | Cutting, machining, welding |

| Cost | Lower cost due to thinner material | Higher cost due to thickness and manufacturing |

| Strength | Moderate strength suitable for light-duty | High strength for heavy-duty applications |

Understanding the Difference: Sheet Metal vs Plate Metal

Sheet metal is typically defined as metal with a thickness less than 6 millimeters, used for applications requiring flexibility and ease of forming, such as automotive bodies and appliances. Plate metal refers to metal thicker than 6 millimeters, offering greater strength and rigidity, commonly used in structural engineering and heavy machinery. Understanding the distinction between sheet and plate metal is crucial for selecting the appropriate material based on thickness, strength, and intended use.

Defining Sheet Metal: Characteristics and Uses

Sheet metal is characterized by its thin, flat pieces of metal typically less than 6mm thick, offering flexibility for bending and cutting in manufacturing processes. It is widely used in automotive bodies, electronics enclosures, and HVAC systems due to its malleability and cost-effectiveness. Common materials for sheet metal include steel, aluminum, copper, and brass, each selected based on application-specific strength and corrosion resistance requirements.

What is Plate Metal? Key Features and Applications

Plate metal refers to metal sheets thicker than 6 mm (0.24 inches), commonly used in heavy-duty structural applications due to its high strength and durability. Key features include excellent load-bearing capacity, resistance to wear and corrosion, and suitability for fabrication processes like welding and machining. It is widely applied in shipbuilding, construction, heavy machinery manufacturing, and industrial equipment where robust, sturdy materials are essential.

Thickness Matters: Gauging Sheet vs Plate Metal

Sheet metal thickness typically ranges from 0.5 mm to 6 mm, whereas plate metal is defined as metal thicker than 6 mm, often reaching up to several inches. The gauge system measures sheet metal thickness, where a higher gauge number indicates a thinner piece, while plate metal thickness is measured in direct units such as millimeters or inches. Selecting between sheet and plate metal depends on the structural strength required, with thicker plate metal providing enhanced durability for heavy-duty applications.

Manufacturing Processes for Sheet and Plate Metal

Sheet metal fabrication involves processes like bending, stamping, and deep drawing, which are suitable for thinner gauges typically under 6 mm, enabling precise and complex shapes. Plate metal manufacturing, catering to thicknesses over 6 mm, primarily uses cutting methods such as plasma cutting, laser cutting, and heavy-duty machining, ensuring structural integrity for heavy-duty applications. Both materials undergo heat treatment and surface finishing processes tailored to their thickness and intended use in industries like automotive, aerospace, and construction.

Common Alloys and Materials Used

Sheet metal commonly utilizes alloys such as aluminum 3003, carbon steel 1018, and stainless steel 304 for its versatility and corrosion resistance. Plate metal often employs high-strength alloys like alloy steel 4130, stainless steel 316, and aluminum 6061 for enhanced durability and structural applications. Both sheet and plate metals favor materials that balance formability with mechanical strength to suit diverse industrial needs.

Strength and Durability Comparison

Sheet metal typically ranges from 0.5 mm to 6 mm in thickness, offering excellent flexibility and moderate strength, making it suitable for applications requiring shaping and bending. Plate metal exceeds 6 mm in thickness, providing significantly higher strength and durability, ideal for structural components subjected to heavy loads and impact. The increased thickness and density of plate metal result in superior resistance to deformation and wear compared to thinner sheet metal.

Cost Considerations: Sheet Metal vs Plate Metal

Sheet metal generally incurs lower costs due to its thinner gauges and ease of fabrication, making it ideal for mass production and applications requiring precision. Plate metal, being thicker and bulkier, demands more material and heavier machinery for processing, resulting in higher expenses for cutting, forming, and transportation. Understanding the specific project requirements helps balance the price differences between sheet metal and plate metal while optimizing budget efficiency.

Ideal Applications for Sheet Metal

Sheet metal is ideal for applications requiring precise bending, cutting, and forming at thinner gauges typically below 6mm, making it perfect for automotive panels, HVAC ducts, and electronic enclosures. Its versatility in fabrication processes such as stamping and punching enables efficient production of complex shapes and lightweight components. Industries focusing on mass production and customizable designs often prefer sheet metal due to its cost-effectiveness and ease of handling.

Best Use Cases for Plate Metal

Plate metal is best used in applications requiring thicker material with greater strength and durability, such as structural beams, heavy-duty machinery, and industrial fabrication. Its increased thickness, typically over 6 mm, provides enhanced load-bearing capacity and resistance to impact compared to sheet metal. Ideal for construction, shipbuilding, and heavy equipment manufacturing, plate metal ensures stability and longevity under demanding conditions.

Sheet Metal vs Plate Metal Infographic

materialdif.com

materialdif.com