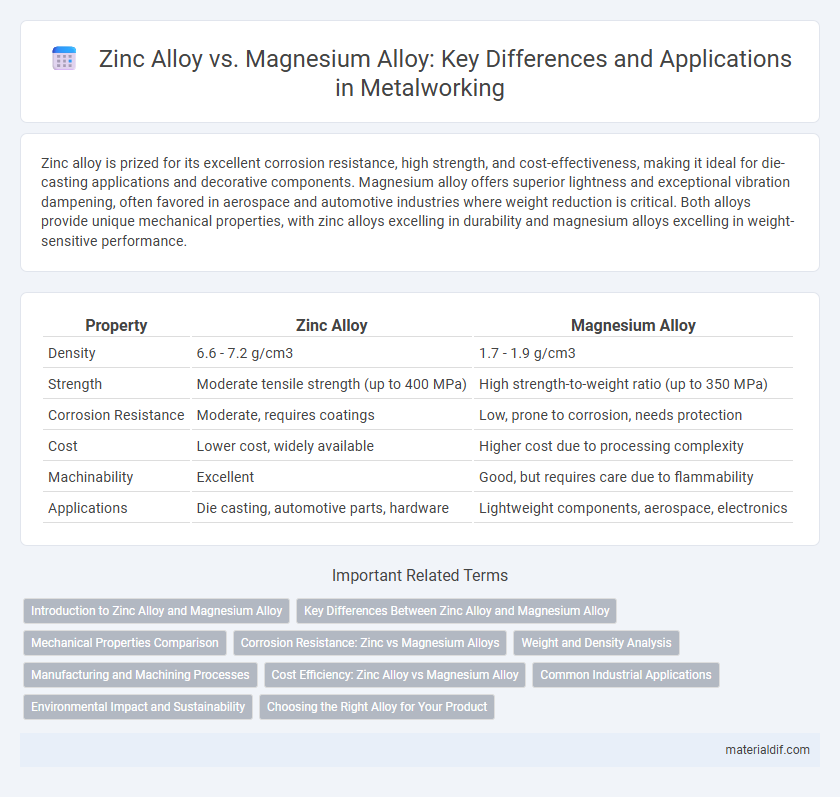

Zinc alloy is prized for its excellent corrosion resistance, high strength, and cost-effectiveness, making it ideal for die-casting applications and decorative components. Magnesium alloy offers superior lightness and exceptional vibration dampening, often favored in aerospace and automotive industries where weight reduction is critical. Both alloys provide unique mechanical properties, with zinc alloys excelling in durability and magnesium alloys excelling in weight-sensitive performance.

Table of Comparison

| Property | Zinc Alloy | Magnesium Alloy |

|---|---|---|

| Density | 6.6 - 7.2 g/cm3 | 1.7 - 1.9 g/cm3 |

| Strength | Moderate tensile strength (up to 400 MPa) | High strength-to-weight ratio (up to 350 MPa) |

| Corrosion Resistance | Moderate, requires coatings | Low, prone to corrosion, needs protection |

| Cost | Lower cost, widely available | Higher cost due to processing complexity |

| Machinability | Excellent | Good, but requires care due to flammability |

| Applications | Die casting, automotive parts, hardware | Lightweight components, aerospace, electronics |

Introduction to Zinc Alloy and Magnesium Alloy

Zinc alloy is a versatile metal combination primarily composed of zinc, often blended with aluminum, copper, and magnesium to enhance strength and corrosion resistance. Magnesium alloy, known for its lightweight and high strength-to-weight ratio, consists mainly of magnesium with small amounts of aluminum, zinc, and manganese to improve mechanical properties. Both alloys are widely used in automotive, aerospace, and consumer electronics industries for their unique balance of durability and weight savings.

Key Differences Between Zinc Alloy and Magnesium Alloy

Zinc alloy offers higher corrosion resistance and superior casting precision compared to magnesium alloy, which is known for its excellent strength-to-weight ratio and lightweight properties. While zinc alloy typically exhibits better wear resistance and is more cost-effective for complex shapes, magnesium alloy provides enhanced thermal conductivity and impact resistance. The choice between these metals depends on application requirements such as durability, weight constraints, and environmental exposure.

Mechanical Properties Comparison

Zinc alloys exhibit high tensile strength and excellent corrosion resistance, making them suitable for durable applications requiring moderate impact resistance. Magnesium alloys are significantly lighter with superior strength-to-weight ratios and excellent fatigue resistance, ideal for aerospace and automotive components where weight reduction is critical. Both metals offer distinct mechanical advantages, with zinc alloys favoring toughness and magnesium alloys excelling in lightweight structural performance.

Corrosion Resistance: Zinc vs Magnesium Alloys

Zinc alloys exhibit superior corrosion resistance compared to magnesium alloys due to their ability to form stable, protective oxide layers that prevent further oxidation. Magnesium alloys are prone to rapid corrosion in moist and saline environments, which significantly limits their long-term durability without extensive surface treatments. The electrochemical potential difference between zinc and magnesium also influences their corrosion behavior, making zinc alloys more suitable for applications requiring enhanced resistance to environmental degradation.

Weight and Density Analysis

Zinc alloy typically has a density around 6.4 to 7.1 g/cm3, making it significantly heavier than magnesium alloy, which ranges from 1.7 to 1.9 g/cm3. This difference in density directly influences the weight, with magnesium alloy components often being 60-70% lighter than those made from zinc alloy. The lightweight properties of magnesium alloy make it highly suitable for applications where weight reduction is critical without compromising mechanical strength.

Manufacturing and Machining Processes

Zinc alloys offer superior casting fluidity and lower melting temperatures, enabling faster and more cost-effective manufacturing compared to magnesium alloys. Magnesium alloys require specialized machining processes due to their lower melting point and higher reactivity, necessitating careful temperature control and tool selection to prevent material degradation. The wear resistance and machinability of zinc alloys make them suitable for high-volume production with tighter tolerances, while magnesium alloys excel in lightweight applications but involve more complex machining considerations.

Cost Efficiency: Zinc Alloy vs Magnesium Alloy

Zinc alloys generally offer superior cost efficiency compared to magnesium alloys due to lower raw material expenses and simpler casting processes. Magnesium alloys, while lighter and stronger, tend to incur higher production costs driven by specialized handling requirements and corrosion protection measures. Manufacturers prioritize zinc alloys when balancing budget constraints with adequate mechanical properties in metal components.

Common Industrial Applications

Zinc alloy is widely used in die casting for automotive components, household appliances, and electronic enclosures due to its excellent corrosion resistance and dimensional stability. Magnesium alloy finds common applications in aerospace, automotive, and electronics industries where lightweight and high strength-to-weight ratio are critical. Both materials offer distinct advantages: zinc alloy excels in intricate designs and cost-effective production, while magnesium alloy is preferred for structural parts requiring reduced weight.

Environmental Impact and Sustainability

Zinc alloys exhibit higher recyclability rates with lower energy consumption during production compared to magnesium alloys, making them more environmentally sustainable. Magnesium alloys, while lightweight and offering fuel efficiency benefits in automotive applications, have a higher carbon footprint due to intensive extraction and processing methods. Sustainable metal selection prioritizes zinc alloys for reduced ecological impact and enhanced circular economy potential in manufacturing.

Choosing the Right Alloy for Your Product

Zinc alloy offers excellent corrosion resistance, superior casting precision, and cost-effectiveness, making it ideal for intricate parts and decorative applications. Magnesium alloy provides lightweight strength and high impact resistance, which benefits automotive, aerospace, and portable electronic products requiring enhanced durability. Selecting the right alloy depends on prioritizing weight reduction versus fine detail and budget constraints for optimal product performance.

Zinc Alloy vs Magnesium Alloy Infographic

materialdif.com

materialdif.com