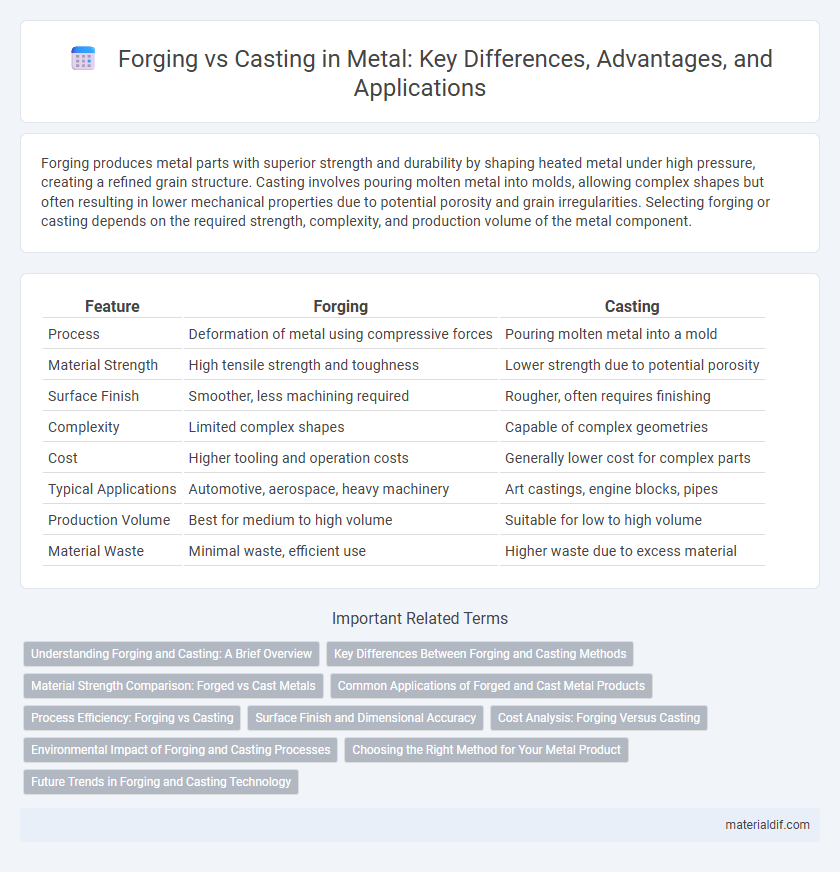

Forging produces metal parts with superior strength and durability by shaping heated metal under high pressure, creating a refined grain structure. Casting involves pouring molten metal into molds, allowing complex shapes but often resulting in lower mechanical properties due to potential porosity and grain irregularities. Selecting forging or casting depends on the required strength, complexity, and production volume of the metal component.

Table of Comparison

| Feature | Forging | Casting |

|---|---|---|

| Process | Deformation of metal using compressive forces | Pouring molten metal into a mold |

| Material Strength | High tensile strength and toughness | Lower strength due to potential porosity |

| Surface Finish | Smoother, less machining required | Rougher, often requires finishing |

| Complexity | Limited complex shapes | Capable of complex geometries |

| Cost | Higher tooling and operation costs | Generally lower cost for complex parts |

| Typical Applications | Automotive, aerospace, heavy machinery | Art castings, engine blocks, pipes |

| Production Volume | Best for medium to high volume | Suitable for low to high volume |

| Material Waste | Minimal waste, efficient use | Higher waste due to excess material |

Understanding Forging and Casting: A Brief Overview

Forging involves shaping metal using compressive forces, typically with hammers or presses, resulting in superior mechanical properties due to grain refinement and enhanced strength. Casting entails pouring molten metal into a mold to achieve complex shapes, making it suitable for intricate designs but often with lower strength compared to forged parts. Understanding the differences in microstructure and material properties between forging and casting is crucial for selecting the appropriate manufacturing process for specific metal components.

Key Differences Between Forging and Casting Methods

Forging involves shaping metal through compressive forces using hammers or presses, resulting in enhanced grain structure and superior mechanical properties such as increased strength and toughness. Casting requires melting metal and pouring it into molds, allowing for complex shapes and internal cavities but often producing components with lower strength and potential porosity issues. Key differences include forging's higher material integrity, better fatigue resistance, and limited shape complexity versus casting's design versatility and cost-effectiveness for large, intricate parts.

Material Strength Comparison: Forged vs Cast Metals

Forged metals exhibit superior material strength due to the aligned grain structure formed during the deformation process, resulting in enhanced toughness and fatigue resistance compared to cast metals. Cast metals often contain porosity and inclusions that can act as stress concentrators, reducing their mechanical performance and making them more susceptible to brittle fracture. The dense, continuous grain flow in forged components provides higher tensile strength and impact resistance crucial for critical load-bearing applications.

Common Applications of Forged and Cast Metal Products

Forged metal products are commonly used in automotive components, aerospace parts, and heavy machinery due to their superior strength and durability. Cast metal products find applications in complex shapes like engine blocks, pump housings, and decorative hardware where intricate detail and cost-effectiveness are prioritized. Industrial valves, tools, and structural components often rely on forging for enhanced mechanical properties, while casting serves well for large, detailed components requiring uniformity.

Process Efficiency: Forging vs Casting

Forging offers superior process efficiency due to its faster production cycles and reduced material waste compared to casting, which involves longer cooling times and potential defects requiring rework. The high mechanical properties in forged metals result from precise deformation under controlled conditions, whereas casting's efficiency is often limited by mold preparation and post-casting heat treatments. Industries prioritize forging for high-strength components demanding quick turnaround and minimal machining, while casting remains efficient for complex shapes with lower volume requirements.

Surface Finish and Dimensional Accuracy

Forging produces metal parts with superior surface finish and higher dimensional accuracy due to the controlled deformation process, resulting in fewer surface imperfections and tighter tolerances. Casting often results in rougher surfaces and greater dimensional variability due to solidification shrinkage and mold surface texture. Precision machining is frequently required after casting to meet exact specifications, whereas forged components typically require less post-processing.

Cost Analysis: Forging Versus Casting

Forging typically incurs higher initial tooling costs compared to casting, but it offers superior mechanical properties that reduce long-term maintenance and failure expenses. Casting allows for more complex geometries at lower upfront costs, making it economically viable for large production runs with intricate designs. Cost analysis must consider factors such as material waste, cycle times, and post-processing requirements to determine the most cost-effective manufacturing method for specific metal components.

Environmental Impact of Forging and Casting Processes

Forging produces less waste and generally consumes less energy compared to casting, making it a more environmentally sustainable metal forming process. Casting involves significant energy use due to melting metals and often generates more scrap and emissions, contributing to a larger carbon footprint. Choosing forging over casting can reduce greenhouse gas emissions and resource depletion in metal manufacturing.

Choosing the Right Method for Your Metal Product

Forging offers superior strength and durability by shaping metal under high pressure, making it ideal for structural components and high-stress applications. Casting allows for more complex shapes and intricate designs with lower tooling costs, suitable for mass production of detailed parts. Selecting the right method depends on the required mechanical properties, design complexity, production volume, and budget constraints to achieve optimal performance and cost-efficiency.

Future Trends in Forging and Casting Technology

Future trends in forging and casting technology emphasize advancements in additive manufacturing integration, enabling complex geometries and reduced material waste. Smart factories equipped with AI-driven process controls optimize production efficiency and ensure higher precision in metal part fabrication. Sustainable practices, including energy-efficient equipment and recycled materials, are increasingly adopted to minimize the environmental impact of forging and casting operations.

Forging vs Casting Infographic

materialdif.com

materialdif.com