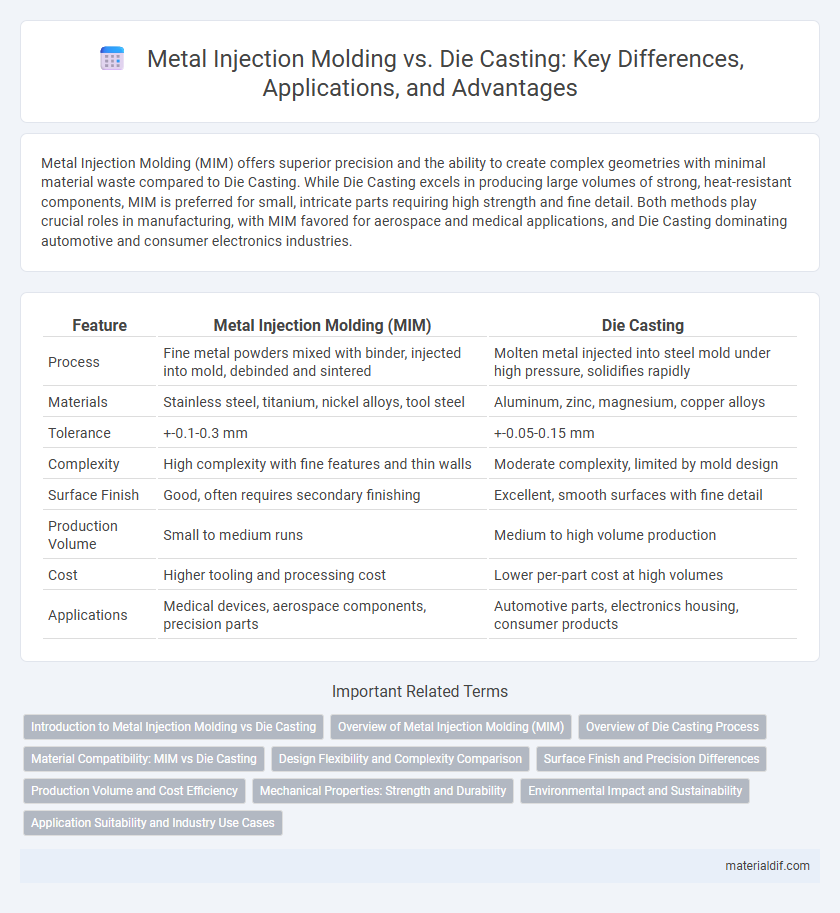

Metal Injection Molding (MIM) offers superior precision and the ability to create complex geometries with minimal material waste compared to Die Casting. While Die Casting excels in producing large volumes of strong, heat-resistant components, MIM is preferred for small, intricate parts requiring high strength and fine detail. Both methods play crucial roles in manufacturing, with MIM favored for aerospace and medical applications, and Die Casting dominating automotive and consumer electronics industries.

Table of Comparison

| Feature | Metal Injection Molding (MIM) | Die Casting |

|---|---|---|

| Process | Fine metal powders mixed with binder, injected into mold, debinded and sintered | Molten metal injected into steel mold under high pressure, solidifies rapidly |

| Materials | Stainless steel, titanium, nickel alloys, tool steel | Aluminum, zinc, magnesium, copper alloys |

| Tolerance | +-0.1-0.3 mm | +-0.05-0.15 mm |

| Complexity | High complexity with fine features and thin walls | Moderate complexity, limited by mold design |

| Surface Finish | Good, often requires secondary finishing | Excellent, smooth surfaces with fine detail |

| Production Volume | Small to medium runs | Medium to high volume production |

| Cost | Higher tooling and processing cost | Lower per-part cost at high volumes |

| Applications | Medical devices, aerospace components, precision parts | Automotive parts, electronics housing, consumer products |

Introduction to Metal Injection Molding vs Die Casting

Metal Injection Molding (MIM) and Die Casting are advanced manufacturing techniques used for producing complex metal parts with high precision and efficiency. MIM combines the versatility of plastic injection molding with the strength and integrity of metal, enabling intricate geometries and fine features in small to medium-sized components. Die Casting involves forcing molten metal into a mold cavity under high pressure, ideal for producing larger volumes of parts with excellent surface finish and dimensional accuracy, especially from non-ferrous alloys like aluminum, zinc, and magnesium.

Overview of Metal Injection Molding (MIM)

Metal Injection Molding (MIM) combines the design flexibility of plastic injection molding with the strength and integrity of powdered metallurgy, enabling the production of complex, high-precision metal parts in large volumes. MIM uses fine metal powders mixed with a binder to create a feedstock that is injected into molds, followed by debinding and sintering processes to achieve dense, functional components. This process is ideal for manufacturing small to medium-sized parts with intricate geometries and tight tolerances, commonly used in industries such as medical devices, aerospace, and automotive.

Overview of Die Casting Process

Die casting is a manufacturing process that forces molten metal under high pressure into reusable steel molds called dies, allowing for precise, complex shapes with excellent surface finishes. This method is especially effective for producing large volumes of components in materials such as aluminum, zinc, and magnesium alloys with tight dimensional tolerances. The die casting process offers rapid production cycles and reduced machining requirements compared to other metal forming techniques like metal injection molding.

Material Compatibility: MIM vs Die Casting

Metal Injection Molding (MIM) offers superior material compatibility for complex, high-performance alloys like stainless steel, titanium, and nickel-based superalloys, enabling intricate designs with exceptional mechanical properties. Die casting primarily supports non-ferrous metals such as aluminum, zinc, and magnesium, making it ideal for high-volume applications but limiting use with high-strength, corrosion-resistant materials. The choice between MIM and die casting hinges on the required material characteristics and the complexity of the final product.

Design Flexibility and Complexity Comparison

Metal Injection Molding (MIM) offers superior design flexibility and can produce highly complex geometries with intricate details, sharp corners, and thin walls that are difficult to achieve with Die Casting. Die Casting is generally limited to simpler shapes and thicker walls due to mold design constraints and metal flow behavior during the casting process. The ability of MIM to create near-net-shape parts with detailed features reduces the need for secondary machining, making it ideal for small, complex components.

Surface Finish and Precision Differences

Metal Injection Molding (MIM) produces parts with superior surface finish and finer detail compared to die casting, achieving near-net-shape components with minimal post-processing. MIM can achieve surface roughness values as low as Ra 0.4 um, whereas die casting typically yields roughness around Ra 3.2 um, resulting in less need for machining. Precision-wise, MIM offers tighter tolerances of +-0.1% to +-0.3%, while die casting tolerances generally range from +-0.25% to +-0.5%, making MIM preferable for intricate, high-precision metal parts.

Production Volume and Cost Efficiency

Metal Injection Molding (MIM) excels in producing small to medium production volumes with high precision and complex geometries, offering cost efficiency for detailed, low to mid-range batch sizes. Die Casting suits high-volume production demands, providing faster cycle times and lower per-unit costs due to economies of scale in mass manufacturing. Choosing between MIM and Die Casting depends on balancing production volume requirements with upfront tooling investments and part complexity.

Mechanical Properties: Strength and Durability

Metal injection molding (MIM) produces components with superior uniformity and fine microstructures, resulting in enhanced mechanical strength and wear resistance compared to die casting. Die casting typically yields parts with higher density and greater tensile strength but can suffer from porosity and internal defects that reduce overall durability. Selecting between MIM and die casting depends on the balance of mechanical properties required, with MIM offering better fatigue resistance and die casting excelling in impact strength.

Environmental Impact and Sustainability

Metal Injection Molding (MIM) significantly reduces material waste by utilizing finely powdered metals and near-net-shape production, leading to less scrap compared to Die Casting, which often requires larger metal volumes and generates more leftover material. MIM processes consume lower energy due to reduced need for post-processing and machining, while Die Casting typically involves high energy input for melting and casting large metal amounts. The environmental footprint of MIM is further minimized through its ability to recycle powder feedstock, supporting sustainable manufacturing practices over the more resource-intensive Die Casting method.

Application Suitability and Industry Use Cases

Metal Injection Molding (MIM) excels in producing intricate, small to medium-sized components with complex geometries, ideal for aerospace, medical devices, and electronics industries requiring high precision and lightweight parts. Die Casting is preferable for high-volume production of larger, robust components with excellent surface finish, frequently used in automotive, consumer electronics, and industrial machinery sectors. Both technologies cater to specific application needs, with MIM suited for detailed, durable parts and Die Casting optimized for mass production of structural components.

Metal Injection Molding vs Die Casting Infographic

materialdif.com

materialdif.com