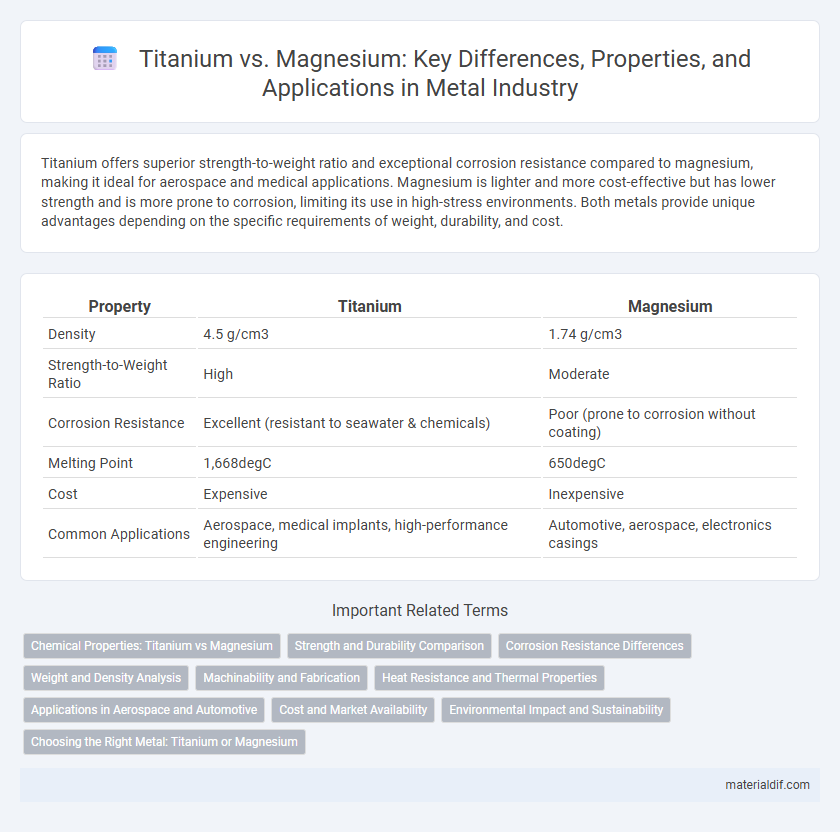

Titanium offers superior strength-to-weight ratio and exceptional corrosion resistance compared to magnesium, making it ideal for aerospace and medical applications. Magnesium is lighter and more cost-effective but has lower strength and is more prone to corrosion, limiting its use in high-stress environments. Both metals provide unique advantages depending on the specific requirements of weight, durability, and cost.

Table of Comparison

| Property | Titanium | Magnesium |

|---|---|---|

| Density | 4.5 g/cm3 | 1.74 g/cm3 |

| Strength-to-Weight Ratio | High | Moderate |

| Corrosion Resistance | Excellent (resistant to seawater & chemicals) | Poor (prone to corrosion without coating) |

| Melting Point | 1,668degC | 650degC |

| Cost | Expensive | Inexpensive |

| Common Applications | Aerospace, medical implants, high-performance engineering | Automotive, aerospace, electronics casings |

Chemical Properties: Titanium vs Magnesium

Titanium exhibits a higher corrosion resistance and maintains stability at elevated temperatures due to the formation of a protective oxide layer, whereas magnesium is more reactive and prone to oxidation in moist environments. Chemically, titanium is a transition metal with a tendency to form +4 oxidation states, contrasting with magnesium, an alkaline earth metal that primarily forms +2 oxidation states in its compounds. The distinct chemical behaviors influence their applications, with titanium favored in aerospace and biomedical fields for its durability and magnesium used in lightweight alloy production where cost-effectiveness is critical.

Strength and Durability Comparison

Titanium offers superior strength-to-weight ratio with tensile strength ranging from 434 to 1,400 MPa, significantly outperforming magnesium, which typically has tensile strength between 160 to 250 MPa. Titanium's exceptional corrosion resistance and fatigue strength contribute to its enhanced durability in harsh environments, whereas magnesium is more prone to corrosion and mechanical wear. These attributes make titanium the preferred choice in aerospace and medical applications where long-term structural integrity is critical.

Corrosion Resistance Differences

Titanium exhibits superior corrosion resistance compared to magnesium due to its stable oxide layer that prevents further oxidation in harsh environments. Magnesium, while lightweight, is more prone to corrosion, especially in salty or humid conditions, necessitating protective coatings for durability. This difference makes titanium the preferred choice for aerospace and marine applications requiring long-term exposure to corrosive elements.

Weight and Density Analysis

Titanium has a density of approximately 4.5 g/cm3, making it significantly heavier than magnesium, which has a density around 1.74 g/cm3. Despite its higher density, titanium's strength-to-weight ratio allows for weight-efficient applications in aerospace and medical industries. Magnesium's lower density contributes to lighter structures but typically requires alloying to enhance strength for practical use.

Machinability and Fabrication

Titanium offers superior corrosion resistance and strength but exhibits lower machinability due to its toughness and tendency to cause tool wear, requiring specialized cutting tools and slower speeds. Magnesium is highly machinable with excellent chip flow and faster cutting rates, making it ideal for rapid fabrication, although it lacks the strength and corrosion resistance of titanium. Choosing between titanium and magnesium depends on balancing machinability needs with mechanical properties for specific applications.

Heat Resistance and Thermal Properties

Titanium exhibits superior heat resistance with a melting point of approximately 1668degC, making it ideal for high-temperature applications compared to magnesium's melting point of about 650degC. Titanium's thermal conductivity is lower, around 21.9 W/m*K, which contributes to better thermal stability and insulation under extreme heat. Magnesium's higher thermal conductivity, near 156 W/m*K, allows for faster heat dissipation but limits its use in prolonged high-temperature environments.

Applications in Aerospace and Automotive

Titanium's exceptional strength-to-weight ratio and corrosion resistance make it ideal for aerospace components like airframes, engine parts, and landing gear, improving fuel efficiency and safety. Magnesium, being lighter but less strong, is widely used in automotive applications for manufacturing lightweight wheels, engine blocks, and transmission cases, enhancing vehicle performance and fuel economy. Both metals contribute significantly to reducing weight and increasing efficiency in transportation industries, with titanium favored for high-stress aerospace parts and magnesium preferred for cost-effective automotive solutions.

Cost and Market Availability

Titanium typically costs between $6 to $10 per pound, making it significantly more expensive than magnesium, which ranges from $2 to $3 per pound. The market availability of magnesium is broader due to its abundant reserves and simpler extraction processes, while titanium's availability is limited by more complex mining and processing requirements. Industries often choose magnesium for cost-sensitive applications, whereas titanium is preferred for high-performance uses despite its higher price and constrained supply.

Environmental Impact and Sustainability

Titanium offers superior corrosion resistance and recyclability, resulting in a lower environmental footprint compared to magnesium, which is more prone to oxidation and requires more energy-intensive processing. The extraction of titanium involves complex processes generating significant CO2 emissions, yet its longevity and recyclability enhance overall sustainability. Magnesium's lighter weight is advantageous for reducing vehicle emissions, but challenges in recycling and higher production energy costs limit its environmental benefits.

Choosing the Right Metal: Titanium or Magnesium

Titanium offers exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, making it ideal for aerospace and medical applications. Magnesium is significantly lighter and more cost-effective, suitable for automotive and electronic components where weight reduction is critical. Selecting between titanium and magnesium depends on balancing factors like mechanical strength, corrosion resistance, weight priorities, and budget constraints in the intended application.

Titanium vs Magnesium Infographic

materialdif.com

materialdif.com