Diamond turning offers ultra-precise surface finishes and is ideal for intricate metal components requiring nanometer-scale accuracy, while CNC milling excels in versatile metal shaping with high repeatability and faster production times. Diamond turning is preferred for optical-grade metals and fine features, whereas CNC milling accommodates a broader range of metal types and complex geometries. Choosing between diamond turning and CNC milling depends on the required precision, surface quality, and production volume.

Table of Comparison

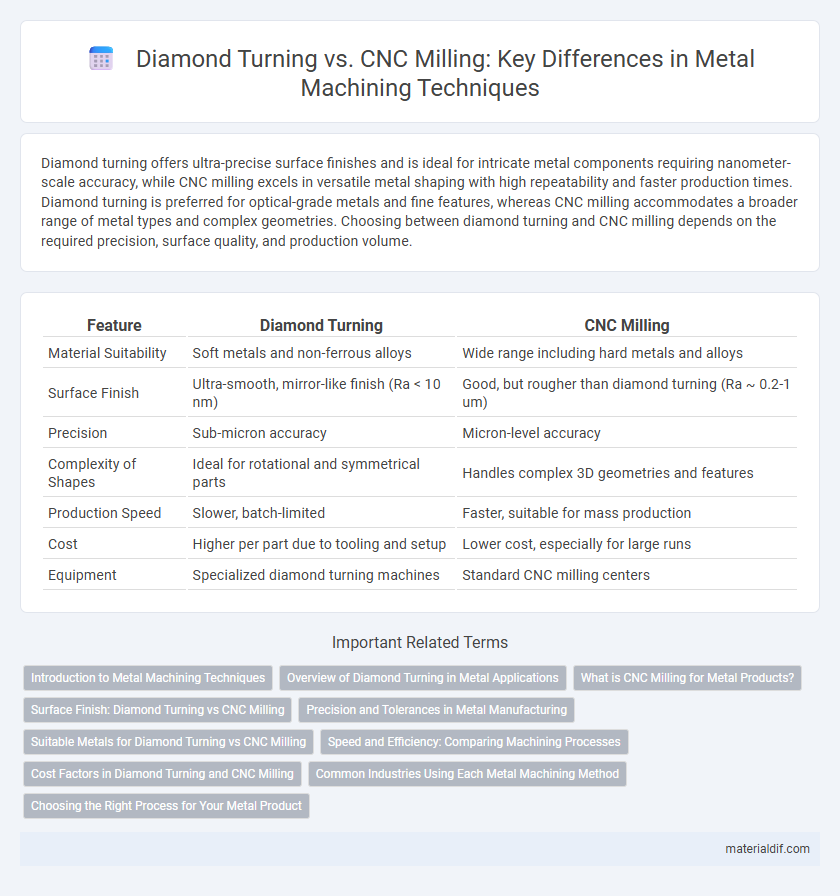

| Feature | Diamond Turning | CNC Milling |

|---|---|---|

| Material Suitability | Soft metals and non-ferrous alloys | Wide range including hard metals and alloys |

| Surface Finish | Ultra-smooth, mirror-like finish (Ra < 10 nm) | Good, but rougher than diamond turning (Ra ~ 0.2-1 um) |

| Precision | Sub-micron accuracy | Micron-level accuracy |

| Complexity of Shapes | Ideal for rotational and symmetrical parts | Handles complex 3D geometries and features |

| Production Speed | Slower, batch-limited | Faster, suitable for mass production |

| Cost | Higher per part due to tooling and setup | Lower cost, especially for large runs |

| Equipment | Specialized diamond turning machines | Standard CNC milling centers |

Introduction to Metal Machining Techniques

Diamond turning offers ultra-precise surface finishes on metals like aluminum and copper, utilizing a single-point diamond tool for nanometer-level accuracy. CNC milling, by contrast, employs rotary cutting tools to shape metals such as steel and titanium with high versatility and complex geometries. Both techniques are essential in metal machining, with diamond turning excelling in optical components and CNC milling dominating general manufacturing applications.

Overview of Diamond Turning in Metal Applications

Diamond turning in metal applications offers ultra-precision machining capable of achieving nanometer-level surface finishes and sub-micron tolerances on hard materials like aluminum, copper, and titanium. This process uses a single-point diamond cutting tool to create complex optical-quality surfaces, making it essential for manufacturing high-precision components in aerospace, optics, and electronics industries. It outperforms CNC milling in surface quality and accuracy but is limited by material type and production volume constraints.

What is CNC Milling for Metal Products?

CNC milling for metal products is a precision machining process that uses computer-controlled rotating cutting tools to remove material from a metal workpiece, creating complex shapes and high-tolerance components. This process supports diverse metals such as aluminum, steel, titanium, and brass, ensuring consistent surface finishes and intricate detail. CNC milling enables scalable production with repeatable accuracy, making it suitable for aerospace, automotive, and medical metal parts manufacturing.

Surface Finish: Diamond Turning vs CNC Milling

Diamond turning achieves superior surface finish compared to CNC milling due to its ultra-precise single-point cutting method, producing mirror-like, sub-micron smoothness ideal for optical-quality metals. CNC milling typically results in rougher surfaces with visible tool marks, requiring additional polishing for similar smoothness. The surface roughness achieved by diamond turning can be less than 10 nanometers Ra, whereas CNC milling surfaces often range above 100 nanometers Ra.

Precision and Tolerances in Metal Manufacturing

Diamond turning achieves nanometer-level surface finishes and sub-micron tolerances, making it ideal for producing ultra-precise metal components such as optical molds and aerospace parts. CNC milling offers versatility with tolerances typically around +-0.01 mm, suitable for complex geometries but less precise compared to diamond turning. For applications demanding exceptional surface quality and minute dimensional accuracy, diamond turning outperforms CNC milling in metal manufacturing precision and tolerance control.

Suitable Metals for Diamond Turning vs CNC Milling

Diamond turning is ideal for non-ferrous metals such as aluminum, copper, brass, and certain alloys due to its precision and ability to achieve ultra-smooth surface finishes. CNC milling, in contrast, is versatile and suitable for a wider range of metals including steels, stainless steel, titanium, and harder ferrous alloys, accommodating complex geometries and tougher materials. Selecting the appropriate machining method depends on the metal's hardness, thermal conductivity, and the required surface finish quality.

Speed and Efficiency: Comparing Machining Processes

Diamond turning offers superior speed and efficiency in producing ultra-precise metal components with minimal surface finishing compared to CNC milling. CNC milling is versatile but generally slower due to multiple passes and tool changes required for complex geometries. The single-point diamond turning process reduces cycle times significantly, making it ideal for high-volume production of reflective metal parts like aluminum and copper alloys.

Cost Factors in Diamond Turning and CNC Milling

Diamond turning typically incurs higher initial costs due to the precision machinery and specialized diamond tooling required, but it offers lower long-term expenses through reduced material waste and minimal finishing. CNC milling involves lower upfront investment and more versatile tooling options, yet often leads to increased operational costs from multiple tool changes and secondary finishing processes. The choice between these methods greatly depends on part complexity, tolerances, and production volume, where diamond turning excels in high-precision applications while CNC milling provides cost-effective flexibility.

Common Industries Using Each Metal Machining Method

Diamond turning is extensively used in the optics, aerospace, and medical device industries for producing highly precise, mirror-finished surfaces on metals like aluminum and copper alloys. CNC milling dominates automotive, aerospace, and heavy machinery sectors due to its versatility in machining complex parts from harder metals like stainless steel and titanium. Both methods are integral to precision manufacturing, with diamond turning favored for ultra-fine finishes and CNC milling preferred for robust, versatile metal shaping.

Choosing the Right Process for Your Metal Product

Diamond turning offers ultra-precision finishing with nanometer-level surface quality, ideal for complex geometries and optical components in metals like aluminum and copper alloys. CNC milling provides greater versatility and faster material removal for a wide range of metal types, including steel, titanium, and cast iron, making it suitable for robust mechanical parts. Selecting between diamond turning and CNC milling depends on the required surface finish, material hardness, and production volume.

Diamond Turning vs CNC Milling Infographic

materialdif.com

materialdif.com