Galvanized steel features a protective zinc coating applied through a hot-dip process, enhancing corrosion resistance and durability in outdoor and industrial settings. Electroplated steel receives a thin metallic layer via electrochemical deposition, offering precise control over coating thickness and superior surface finish for decorative and electronic applications. Choosing between galvanized and electroplated steel depends on environmental exposure, required corrosion protection, and aesthetic considerations.

Table of Comparison

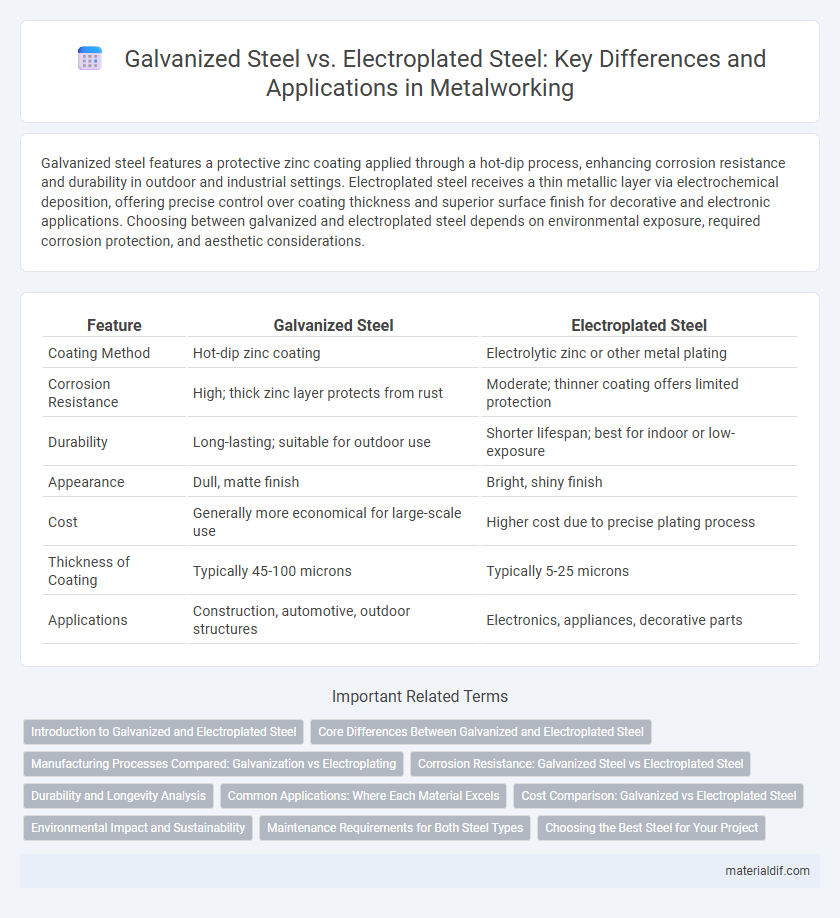

| Feature | Galvanized Steel | Electroplated Steel |

|---|---|---|

| Coating Method | Hot-dip zinc coating | Electrolytic zinc or other metal plating |

| Corrosion Resistance | High; thick zinc layer protects from rust | Moderate; thinner coating offers limited protection |

| Durability | Long-lasting; suitable for outdoor use | Shorter lifespan; best for indoor or low-exposure |

| Appearance | Dull, matte finish | Bright, shiny finish |

| Cost | Generally more economical for large-scale use | Higher cost due to precise plating process |

| Thickness of Coating | Typically 45-100 microns | Typically 5-25 microns |

| Applications | Construction, automotive, outdoor structures | Electronics, appliances, decorative parts |

Introduction to Galvanized and Electroplated Steel

Galvanized steel is coated with a layer of zinc through hot-dip galvanizing or electro-galvanizing processes, providing robust corrosion resistance for outdoor and industrial applications. Electroplated steel involves depositing a thin metal layer onto the steel surface using an electric current, offering enhanced surface hardness and aesthetic appeal. Both methods extend steel lifespan, with galvanized steel excelling in heavy-duty protection and electroplated steel preferred for decorative and precision-coated components.

Core Differences Between Galvanized and Electroplated Steel

Galvanized steel is coated with a layer of zinc through a hot-dip process, providing robust corrosion resistance especially suited for outdoor applications. Electroplated steel undergoes an electrochemical process where a thin, precise metal layer like chromium or nickel is deposited, offering enhanced surface finish and moderate protection. The core difference lies in the coating thickness and durability, with galvanized steel providing thicker, long-lasting protection, while electroplated steel prioritizes aesthetic appeal and uniformity.

Manufacturing Processes Compared: Galvanization vs Electroplating

Galvanization involves coating steel with a layer of zinc through a hot-dip process, creating a robust barrier that prevents corrosion and extends the metal's lifespan. Electroplating uses an electrical current to deposit a thin, uniform metallic layer, often nickel or chromium, enhancing surface aesthetics and corrosion resistance but requiring precise control during manufacturing. The hot-dip galvanization process is generally more cost-effective for large-scale applications, while electroplating offers superior finish quality and is better suited for intricate or decorative steel components.

Corrosion Resistance: Galvanized Steel vs Electroplated Steel

Galvanized steel offers superior corrosion resistance due to its thicker zinc coating, which provides a robust barrier against moisture and oxygen, preventing rust formation over time. Electroplated steel, coated with a thin layer of zinc or other metals, provides less durability and tends to wear off faster, making it less effective in harsh or prolonged exposure to corrosive environments. The longer lifespan and maintenance-free nature of galvanized steel make it the preferred choice for outdoor and industrial applications where corrosion resistance is critical.

Durability and Longevity Analysis

Galvanized steel offers superior durability due to its thick zinc coating that provides robust corrosion resistance, significantly extending the metal's lifespan in harsh environments. Electroplated steel, while offering a smoother and more decorative finish, typically has a thinner protective layer, making it more susceptible to wear and corrosion over time. Choosing galvanized steel enhances longevity in structural and outdoor applications where exposure to moisture and chemicals is prevalent.

Common Applications: Where Each Material Excels

Galvanized steel, coated with a layer of zinc, excels in outdoor and industrial applications such as construction, automotive parts, and agricultural equipment due to its superior corrosion resistance. Electroplated steel, with its thin, uniform metallic coating, is preferred in electronics, decorative fixtures, and precision components where enhanced surface finish and conductivity are crucial. Each material's protective properties and finish determine its suitability, with galvanized steel favored for durability and electroplated steel for aesthetic and functional surface enhancements.

Cost Comparison: Galvanized vs Electroplated Steel

Galvanized steel generally offers a lower initial cost compared to electroplated steel due to its simpler hot-dip coating process, which applies a thicker zinc layer for corrosion protection. Electroplated steel involves more complex procedures such as electrolysis, resulting in higher manufacturing expenses and increased labor costs. Over the long term, galvanized steel's durability may reduce maintenance expenses, offering better cost-efficiency in industrial applications.

Environmental Impact and Sustainability

Galvanized steel features a zinc coating applied through hot-dip galvanization, providing long-lasting corrosion resistance and enhanced recyclability, which reduces environmental impact by extending the steel's lifespan and minimizing resource extraction. Electroplated steel involves a thin metal layer deposited via electrochemical processes that consume more energy and produce hazardous waste, posing greater sustainability challenges compared to galvanizing. Choosing galvanized steel supports circular economy principles by enabling easier material recovery and lowering the carbon footprint associated with protective metal coatings.

Maintenance Requirements for Both Steel Types

Galvanized steel requires minimal maintenance due to its thick zinc coating that provides long-lasting corrosion resistance, reducing the need for frequent inspections or repairs. Electroplated steel, with its thinner metal layer, demands more frequent maintenance and touch-ups to prevent rust and corrosion, especially in harsh environments. Proper cleaning and timely reapplication of protective coatings are essential to extend the lifespan of electroplated steel surfaces.

Choosing the Best Steel for Your Project

Galvanized steel features a durable zinc coating that provides superior corrosion resistance, ideal for outdoor and industrial applications requiring long-term protection. Electroplated steel offers a thinner metal coating, such as chrome or nickel, suited for decorative purposes or light wear environments where aesthetics and surface smoothness are priorities. Evaluating the project's environmental exposure, longevity requirements, and budget will determine whether galvanized steel's robust defense or electroplated steel's refined finish is the optimal choice.

Galvanized Steel vs Electroplated Steel Infographic

materialdif.com

materialdif.com