316 stainless steel contains molybdenum, which enhances its corrosion resistance, especially against chlorides and marine environments, making it ideal for harsh conditions. 304 stainless steel, composed primarily of iron, chromium, and nickel, offers excellent formability and general corrosion resistance but is less resistant to salt and acidic environments. Choosing between 316 and 304 stainless depends on the specific environmental exposure and durability requirements of the application.

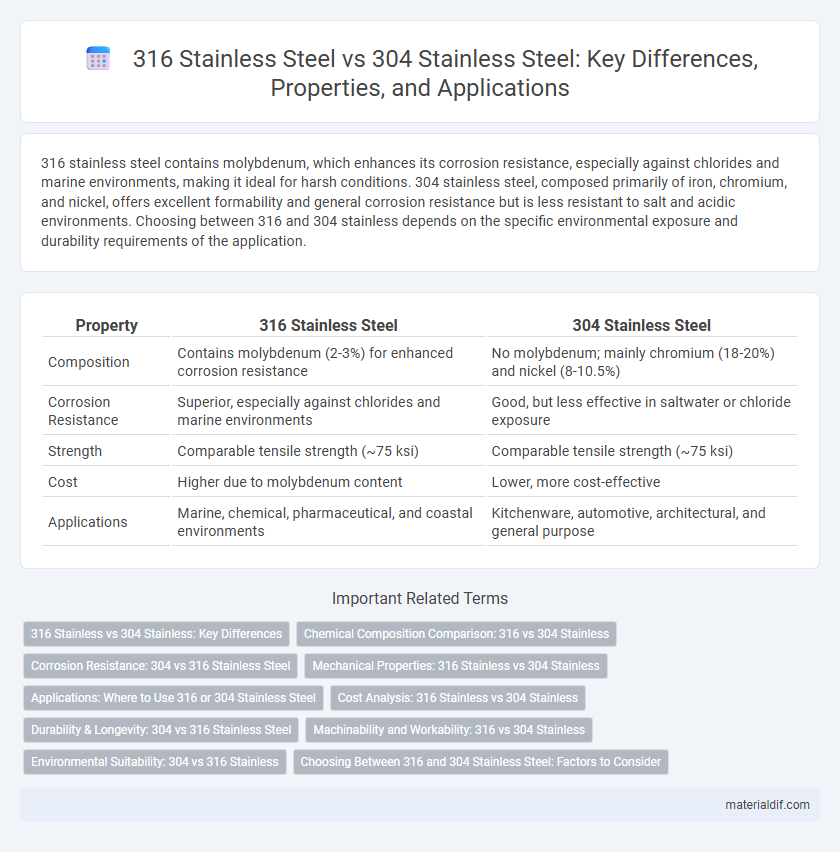

Table of Comparison

| Property | 316 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Composition | Contains molybdenum (2-3%) for enhanced corrosion resistance | No molybdenum; mainly chromium (18-20%) and nickel (8-10.5%) |

| Corrosion Resistance | Superior, especially against chlorides and marine environments | Good, but less effective in saltwater or chloride exposure |

| Strength | Comparable tensile strength (~75 ksi) | Comparable tensile strength (~75 ksi) |

| Cost | Higher due to molybdenum content | Lower, more cost-effective |

| Applications | Marine, chemical, pharmaceutical, and coastal environments | Kitchenware, automotive, architectural, and general purpose |

316 Stainless vs 304 Stainless: Key Differences

316 stainless steel contains molybdenum, enhancing its corrosion resistance, especially against chlorides and marine environments, compared to 304 stainless steel. 304 stainless steel has a lower resistance to pitting and crevice corrosion, making 316 the preferred choice for harsh chemical or saltwater applications. The mechanical properties of both alloys are similar, but 316 Stainless offers superior durability in aggressive environments.

Chemical Composition Comparison: 316 vs 304 Stainless

316 stainless steel contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, which enhances corrosion resistance compared to 304 stainless steel's 18-20% chromium and 8-12% nickel without molybdenum. The addition of molybdenum in 316 stainless significantly improves resistance to chlorides and marine environments, making it ideal for harsh conditions. Both grades maintain similar carbon levels around 0.08%, but the key chemical difference lies in the molybdenum content that defines their corrosion performance.

Corrosion Resistance: 304 vs 316 Stainless Steel

316 stainless steel offers superior corrosion resistance compared to 304 stainless steel due to the addition of molybdenum, which enhances its ability to withstand chlorides and marine environments. While 304 stainless steel resists oxidation and general corrosion effectively, it is more susceptible to pitting and crevice corrosion in saltwater conditions. This makes 316 stainless steel the preferred choice for applications exposed to harsh corrosive environments like chemical processing, coastal architecture, and marine equipment.

Mechanical Properties: 316 Stainless vs 304 Stainless

316 stainless steel exhibits higher tensile strength and better corrosion resistance compared to 304 stainless steel, making it ideal for harsher environments. The yield strength of 316 stainless typically ranges between 30,000 to 40,000 psi, surpassing that of 304 stainless, which generally falls around 25,000 to 35,000 psi. Enhanced mechanical properties of 316 stainless steel contribute to its superior durability and resistance to stress in marine and chemical processing applications.

Applications: Where to Use 316 or 304 Stainless Steel

316 stainless steel is ideal for marine environments, chemical processing, and medical implants due to its superior corrosion resistance against chlorides and harsh chemicals. 304 stainless steel is commonly used in household appliances, food processing equipment, and architectural applications where moderate corrosion resistance and cost-effectiveness are key. Choosing 316 or 304 stainless steel depends on exposure conditions, with 316 preferred for highly corrosive or saline environments and 304 suitable for general-purpose uses.

Cost Analysis: 316 Stainless vs 304 Stainless

316 stainless steel typically costs 20-30% more than 304 stainless steel due to the addition of molybdenum, which enhances corrosion resistance. The higher material cost of 316 stainless is often justified in applications exposed to harsh environments such as marine or chemical processing industries where durability offsets initial expenses. In contrast, 304 stainless steel remains the economical choice for general purposes with moderate corrosion resistance and lower upfront investment.

Durability & Longevity: 304 vs 316 Stainless Steel

316 stainless steel offers superior durability and corrosion resistance compared to 304 stainless steel, making it ideal for harsh environments like marine or chemical exposure. The higher molybdenum content in 316 enhances its ability to withstand pitting and crevice corrosion, significantly extending its longevity in aggressive conditions. 304 stainless steel remains suitable for general applications but lacks the enhanced corrosion protection and lifespan of 316 grade.

Machinability and Workability: 316 vs 304 Stainless

316 stainless steel features molybdenum, enhancing its corrosion resistance but making it slightly harder to machine compared to 304 stainless steel. 304 stainless offers superior workability and is often preferred for applications requiring extensive forming and bending. Both grades perform well in machining, yet 304 stainless typically allows faster cutting speeds and smoother finishes due to its lower strength and less aggressive alloying elements.

Environmental Suitability: 304 vs 316 Stainless

316 stainless steel offers superior environmental resistance compared to 304 stainless, particularly in harsh settings involving saltwater or chemical exposure due to its molybdenum content, which enhances corrosion resistance. 304 stainless steel performs well in typical indoor environments and mildly corrosive conditions but is more susceptible to rust and pitting in marine or industrial atmospheres. For applications requiring long-term durability in aggressive environments, 316 stainless maintains structural integrity better than 304 stainless steel.

Choosing Between 316 and 304 Stainless Steel: Factors to Consider

Choosing between 316 and 304 stainless steel depends on corrosion resistance requirements and environmental conditions. 316 stainless steel contains molybdenum, enhancing its resistance to chloride and saltwater corrosion, making it ideal for marine or chemical environments. In contrast, 304 stainless steel is suitable for general-purpose applications with moderate corrosion exposure, offering cost efficiency and ease of fabrication.

316 Stainless vs 304 Stainless Infographic

materialdif.com

materialdif.com