Galvanized steel offers enhanced corrosion resistance due to its zinc coating, making it ideal for outdoor and industrial applications where exposure to moisture is frequent. Stainless steel contains chromium, providing superior rust resistance and strength while maintaining an attractive finish, suited for environments requiring durability and aesthetic appeal. Choosing between galvanized steel and stainless steel depends on factors like budget, environmental conditions, and desired lifespan.

Table of Comparison

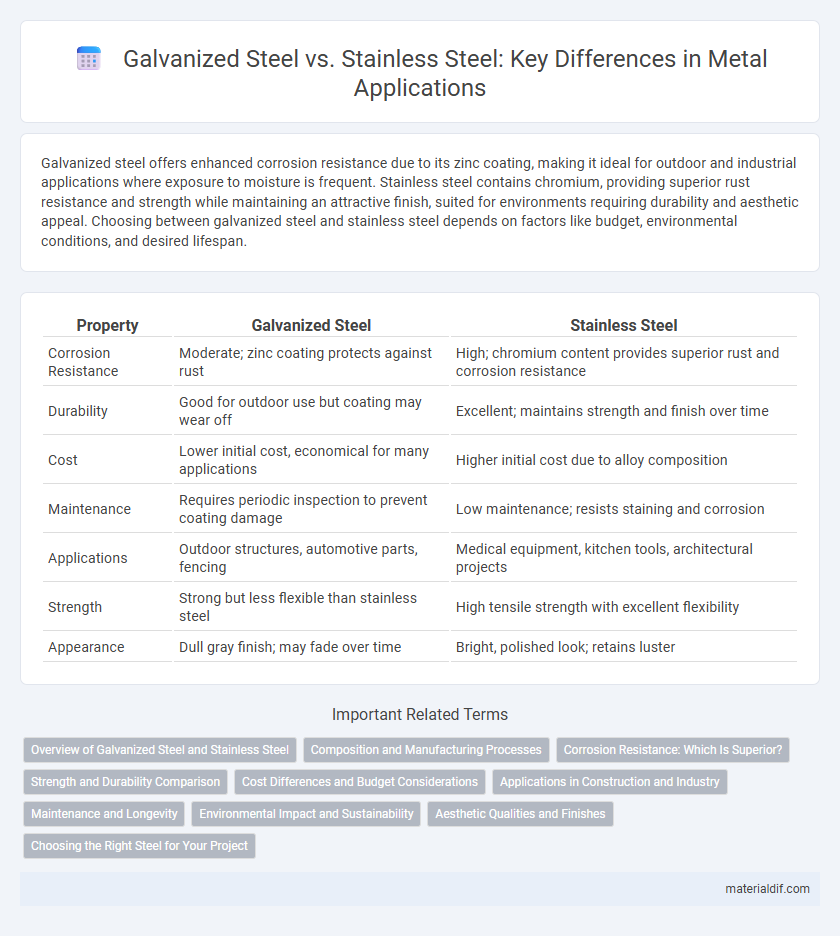

| Property | Galvanized Steel | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Moderate; zinc coating protects against rust | High; chromium content provides superior rust and corrosion resistance |

| Durability | Good for outdoor use but coating may wear off | Excellent; maintains strength and finish over time |

| Cost | Lower initial cost, economical for many applications | Higher initial cost due to alloy composition |

| Maintenance | Requires periodic inspection to prevent coating damage | Low maintenance; resists staining and corrosion |

| Applications | Outdoor structures, automotive parts, fencing | Medical equipment, kitchen tools, architectural projects |

| Strength | Strong but less flexible than stainless steel | High tensile strength with excellent flexibility |

| Appearance | Dull gray finish; may fade over time | Bright, polished look; retains luster |

Overview of Galvanized Steel and Stainless Steel

Galvanized steel features a protective zinc coating to prevent rust and corrosion, making it ideal for outdoor and industrial applications where durability is essential. Stainless steel, composed primarily of iron, chromium, and nickel, offers superior corrosion resistance and strength, commonly used in environments requiring hygiene and resistance to extreme conditions. Both materials serve distinct purposes based on their composition and protective properties, influencing their selection in construction, automotive, and manufacturing industries.

Composition and Manufacturing Processes

Galvanized steel consists of carbon steel coated with a layer of zinc to prevent corrosion, achieved through hot-dip galvanizing or electro-galvanizing processes. Stainless steel is an alloy primarily composed of iron, chromium (at least 10.5%), and varying amounts of nickel and molybdenum, manufactured through melting and casting followed by annealing and passivation for enhanced corrosion resistance. The galvanizing process focuses on surface coating, while stainless steel production integrates alloying elements within the metal matrix for intrinsic durability.

Corrosion Resistance: Which Is Superior?

Stainless steel offers superior corrosion resistance due to its chromium content, which forms a passive oxide layer preventing rust and oxidation. Galvanized steel, coated with a layer of zinc, provides effective protection against corrosion primarily in outdoor and humid environments but can deteriorate once the zinc layer is compromised. For long-term durability in harsh or chloride-rich environments, stainless steel outperforms galvanized steel in maintaining structural integrity and resisting corrosion.

Strength and Durability Comparison

Galvanized steel features a zinc coating that enhances corrosion resistance, making it robust for outdoor and industrial applications, while stainless steel contains chromium that forms a passive layer, offering superior resistance to rust and longer lifespan. Stainless steel generally exhibits higher tensile strength and durability under extreme conditions compared to galvanized steel, which is more prone to wear and corrosion over time despite its protective layer. The choice between galvanized and stainless steel depends on specific environmental exposure and mechanical stress requirements, with stainless steel favored for demanding, corrosive, or high-strength applications.

Cost Differences and Budget Considerations

Galvanized steel typically costs less than stainless steel due to its zinc coating, which provides corrosion resistance at a lower material price point. Stainless steel, made primarily of iron, chromium, and nickel, offers superior durability and corrosion resistance but comes with a higher upfront cost. Budget considerations must balance initial expenditure against long-term maintenance, as galvanized steel may require more frequent replacement or upkeep in harsh environments.

Applications in Construction and Industry

Galvanized steel is widely used in construction for structural frameworks, roofing, and outdoor applications due to its corrosion-resistant zinc coating, which protects against rust in harsh environments. Stainless steel is preferred in industrial settings requiring high strength and resistance to heat, chemicals, and abrasion, such as in chemical processing plants, food industry equipment, and architectural elements exposed to extreme conditions. Both materials contribute uniquely; galvanized steel offers cost-effective durability for exterior construction, while stainless steel provides superior longevity and hygiene for specialized industrial applications.

Maintenance and Longevity

Galvanized steel requires regular inspection to prevent coating damage and rust, but its zinc layer offers effective corrosion resistance in moderate environments. Stainless steel provides superior durability and low maintenance due to its chromium content, which forms a protective oxide layer resistant to rust and staining. Longevity of stainless steel typically exceeds galvanized steel, especially in harsh or corrosive conditions, making it a preferred choice for long-term applications.

Environmental Impact and Sustainability

Galvanized steel involves a zinc coating process that extends its lifespan but raises concerns due to zinc mining and runoff, which can harm ecosystems. Stainless steel, made primarily from iron, chromium, and nickel, offers superior corrosion resistance and recyclability, reducing the need for frequent replacements and lowering overall carbon emissions. Sustainability assessments favor stainless steel for its durability and high recycling rate, although both materials require energy-intensive production processes.

Aesthetic Qualities and Finishes

Galvanized steel features a distinctive matte gray finish with a spangled pattern created by the zinc coating, offering a rugged and industrial aesthetic ideal for utilitarian or outdoor applications. Stainless steel provides a sleek, polished look with options ranging from mirror-like finishes to brushed textures, enhancing its appeal in architectural and decorative contexts. The corrosion resistance of stainless steel maintains its shiny surface longer, while galvanized steel's finish may dull over time but offers cost-effective protection and a unique visual character.

Choosing the Right Steel for Your Project

Galvanized steel offers superior corrosion resistance due to its zinc coating, making it ideal for outdoor and industrial applications exposed to moisture and harsh environments. Stainless steel provides enhanced durability and aesthetic appeal through its chromium content, better suited for structural components and projects requiring long-term strength and minimal maintenance. Selecting the right steel depends on factors like environmental exposure, budget constraints, and desired lifespan, where galvanized steel excels in cost-effective protection and stainless steel delivers premium performance.

Galvanized Steel vs Stainless Steel Infographic

materialdif.com

materialdif.com