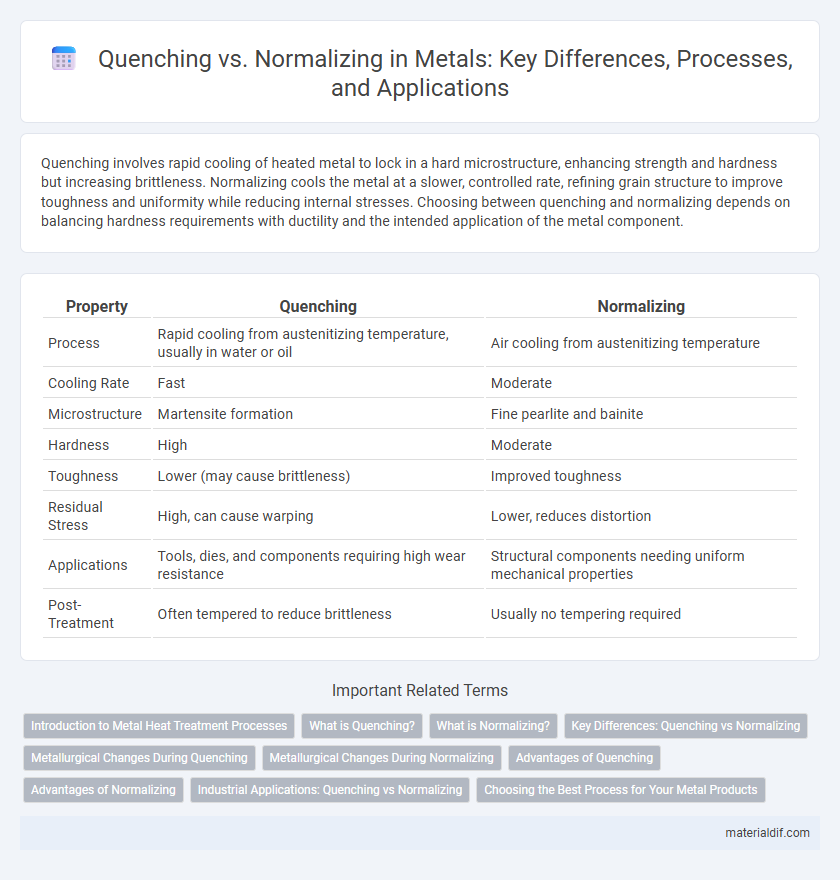

Quenching involves rapid cooling of heated metal to lock in a hard microstructure, enhancing strength and hardness but increasing brittleness. Normalizing cools the metal at a slower, controlled rate, refining grain structure to improve toughness and uniformity while reducing internal stresses. Choosing between quenching and normalizing depends on balancing hardness requirements with ductility and the intended application of the metal component.

Table of Comparison

| Property | Quenching | Normalizing |

|---|---|---|

| Process | Rapid cooling from austenitizing temperature, usually in water or oil | Air cooling from austenitizing temperature |

| Cooling Rate | Fast | Moderate |

| Microstructure | Martensite formation | Fine pearlite and bainite |

| Hardness | High | Moderate |

| Toughness | Lower (may cause brittleness) | Improved toughness |

| Residual Stress | High, can cause warping | Lower, reduces distortion |

| Applications | Tools, dies, and components requiring high wear resistance | Structural components needing uniform mechanical properties |

| Post-Treatment | Often tempered to reduce brittleness | Usually no tempering required |

Introduction to Metal Heat Treatment Processes

Quenching rapidly cools heated metal, typically steel, by immersion in water, oil, or air, enhancing hardness and strength through the formation of martensite microstructure. Normalizing involves heating metal above its critical temperature followed by air cooling to refine grain structure, improve toughness, and relieve internal stresses. Both processes are essential heat treatment methods in metallurgy, optimizing mechanical properties for specific industrial applications such as automotive, aerospace, and tooling.

What is Quenching?

Quenching is a heat treatment process involving rapid cooling of a metal, typically steel, from a high temperature to increase hardness and strength by transforming its microstructure. This process often uses mediums like water, oil, or air to achieve rapid cooling rates that prevent the formation of softer phases such as pearlite or ferrite. Quenching is critical for enhancing wear resistance and mechanical properties in applications requiring high durability.

What is Normalizing?

Normalizing is a heat treatment process for metals where the material is heated above its critical temperature and then air-cooled to refine the grain structure and enhance mechanical properties. This process improves toughness and machinability, reduces internal stresses, and produces a more uniform microstructure compared to quenching. Normalizing is commonly applied to steel to achieve a balanced combination of strength and ductility.

Key Differences: Quenching vs Normalizing

Quenching rapidly cools metal, typically in water or oil, to increase hardness and strength by forming martensite, while normalizing involves air cooling to refine grain structure and improve toughness without increasing hardness significantly. Quenching generates internal stresses requiring subsequent tempering to prevent brittleness, whereas normalizing produces a more uniform microstructure with reduced residual stress. The key difference lies in the cooling rate and resulting mechanical properties: quenching prioritizes hardness and strength, normalizing enhances ductility and fatigue resistance.

Metallurgical Changes During Quenching

Quenching rapidly cools metal, transforming austenite into martensite, a hard and brittle microstructure characterized by a distorted body-centered tetragonal lattice. This rapid cooling suppresses diffusion-dependent phase transformations, resulting in increased hardness and tensile strength but reduced ductility. The metallurgical changes during quenching emphasize the formation of supersaturated solid solutions and residual stresses, essential for enhancing wear resistance in tool steels.

Metallurgical Changes During Normalizing

Normalizing refines the grain structure by heating steel above its critical temperature and cooling it in air, which produces a uniform, fine-grained pearlitic structure. This process enhances ductility and toughness while reducing internal stresses compared to quenching, which rapidly cools steel and forms hard, brittle martensite. Metallurgical changes during normalizing eliminate coarse carbides and promote more homogeneous phase distribution, improving machinability and mechanical properties.

Advantages of Quenching

Quenching enhances metal hardness and strength by rapidly cooling the material, producing a fine martensitic microstructure that improves wear resistance and durability. This process reduces grain size, increasing tensile strength and fatigue resistance, which is critical for high-stress applications. Quenching also minimizes distortion and residual stresses compared to slower cooling methods, ensuring dimensional stability in precision components.

Advantages of Normalizing

Normalizing refines the grain structure of steel, resulting in improved toughness and ductility compared to quenching, which often produces higher hardness but increased brittleness. It reduces internal stresses and distortion, providing dimensional stability critical for precise machining and fabrication. Normalized steels exhibit uniform mechanical properties, enhancing performance in structural applications where consistent strength and resilience are required.

Industrial Applications: Quenching vs Normalizing

Quenching in industrial metalworking is utilized to achieve high hardness and wear resistance by rapidly cooling steel, ideal for components like gears and cutting tools requiring superior strength. Normalizing refines the grain structure and improves machinability by air cooling steel after heating, commonly used in structural parts to enhance toughness and uniformity. Selection between quenching and normalizing depends on desired mechanical properties, with quenching favored for hardness-critical applications and normalizing for balanced strength and ductility.

Choosing the Best Process for Your Metal Products

Selecting the ideal heat treatment for metal products depends on desired mechanical properties, with quenching providing rapid cooling to enhance hardness and strength, while normalizing offers controlled cooling to refine grain structure and improve toughness. Quenching is best for applications requiring maximum hardness and wear resistance, such as cutting tools and automotive components, whereas normalizing suits parts needing uniformity and dimensional stability, like structural steel and forgings. Understanding material composition and end-use conditions is crucial to choosing between quenching and normalizing to optimize performance and durability.

Quenching vs Normalizing Infographic

materialdif.com

materialdif.com