Forged metal offers superior strength and durability due to the continuous grain flow aligned with the shape of the component, making it ideal for high-stress applications. Cast metal allows for more complex shapes and intricate details but typically has a more brittle structure with potential porosity. Choosing between forged and cast metal depends on the required mechanical properties and design complexity of the final product.

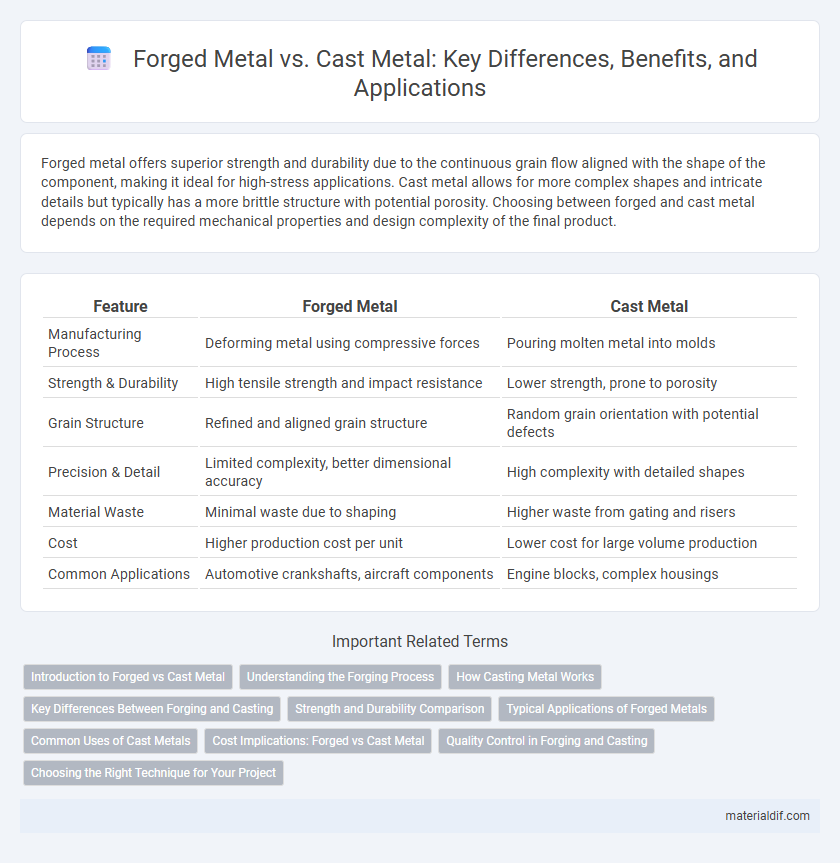

Table of Comparison

| Feature | Forged Metal | Cast Metal |

|---|---|---|

| Manufacturing Process | Deforming metal using compressive forces | Pouring molten metal into molds |

| Strength & Durability | High tensile strength and impact resistance | Lower strength, prone to porosity |

| Grain Structure | Refined and aligned grain structure | Random grain orientation with potential defects |

| Precision & Detail | Limited complexity, better dimensional accuracy | High complexity with detailed shapes |

| Material Waste | Minimal waste due to shaping | Higher waste from gating and risers |

| Cost | Higher production cost per unit | Lower cost for large volume production |

| Common Applications | Automotive crankshafts, aircraft components | Engine blocks, complex housings |

Introduction to Forged vs Cast Metal

Forged metal undergoes shaping through compressive forces, resulting in enhanced grain structure and superior mechanical properties compared to cast metal, which is created by pouring molten metal into molds. The forging process improves strength, fatigue resistance, and toughness, making it ideal for high-stress applications, while casting offers complex shapes and design flexibility but may exhibit internal porosity and reduced strength. Understanding the fundamental differences between forged and cast metals is essential for selecting the appropriate manufacturing method based on performance requirements and application.

Understanding the Forging Process

The forging process involves shaping metal using localized compressive forces, typically delivered by a hammer or a press, resulting in enhanced grain structure and improved mechanical properties compared to cast metal. Forged metal exhibits superior strength, durability, and resistance to impact due to the alignment of internal grains during deformation. This process differs significantly from casting, which involves pouring molten metal into molds, leading to potential porosity and weaker structural integrity.

How Casting Metal Works

Casting metal involves melting metal and pouring it into a mold to obtain a desired shape, allowing for complex geometries and detailed features. The process enables mass production with consistent dimensions, especially for intricate parts that are difficult to achieve through forging. Cooling rates and mold material significantly influence the microstructure and mechanical properties of the cast metal.

Key Differences Between Forging and Casting

Forged metal exhibits superior strength and durability due to its grain structure alignment during the forging process, making it ideal for high-stress applications. Cast metal, shaped by molten metal poured into molds, allows for complex geometries but often has less mechanical strength and higher porosity. Key differences include forging's enhanced mechanical properties and lower defect rates compared to casting's versatility in design and cost-effectiveness for large, intricate shapes.

Strength and Durability Comparison

Forged metal exhibits superior strength and durability compared to cast metal due to its grain structure alignment during the forging process, which enhances toughness and resistance to fatigue. Cast metal often contains internal porosity and inclusions, making it more prone to cracks and failure under high stress or impact. Industries demanding high-performance materials, such as aerospace and automotive sectors, prefer forged components for critical load-bearing applications.

Typical Applications of Forged Metals

Forged metals exhibit superior strength and fatigue resistance, making them ideal for critical applications such as automotive crankshafts, aerospace components, and heavy machinery parts. The dense grain structure formed during forging enhances durability in high-stress environments, which is essential for structural components like connecting rods and turbine blades. This process also enables precise control over mechanical properties, optimizing forged metals for use in tools, gears, and pressure vessels.

Common Uses of Cast Metals

Cast metals are widely used in manufacturing complex shapes and components that require excellent dimensional accuracy, such as engine blocks, pipes, and machinery parts. Their ability to form intricate designs makes them ideal for automotive, aerospace, and construction industries. Cast metals also serve in the production of decorative items, tools, and heavy equipment due to their versatility and strength.

Cost Implications: Forged vs Cast Metal

Forged metal generally incurs higher production costs due to the intensive labor, specialized equipment, and longer processing times involved compared to cast metal. Cast metal offers cost advantages through lower tooling expenses and faster production cycles, making it ideal for complex shapes in large volumes. The choice between forged and cast metal significantly impacts the overall budget, balancing durability requirements with manufacturing efficiency.

Quality Control in Forging and Casting

Forged metal undergoes rigorous quality control processes including ultrasonic testing and dimensional inspections to ensure structural integrity and uniform grain flow, resulting in higher strength and durability. Cast metal quality control focuses on detecting defects such as porosity, shrinkage, and inclusions through radiographic and visual inspections to prevent casting flaws. The controlled deformation in forging leads to fewer internal defects compared to casting, which relies heavily on mold design and solidification control for quality assurance.

Choosing the Right Technique for Your Project

Selecting the right metalworking technique hinges on project requirements such as strength, complexity, and budget. Forged metal offers superior durability and grain structure optimal for high-stress applications, while cast metal excels in creating intricate shapes with precision. Evaluating factors like load-bearing needs and design intricacy ensures the best choice between forging and casting for long-lasting results.

Forged Metal vs Cast Metal Infographic

materialdif.com

materialdif.com