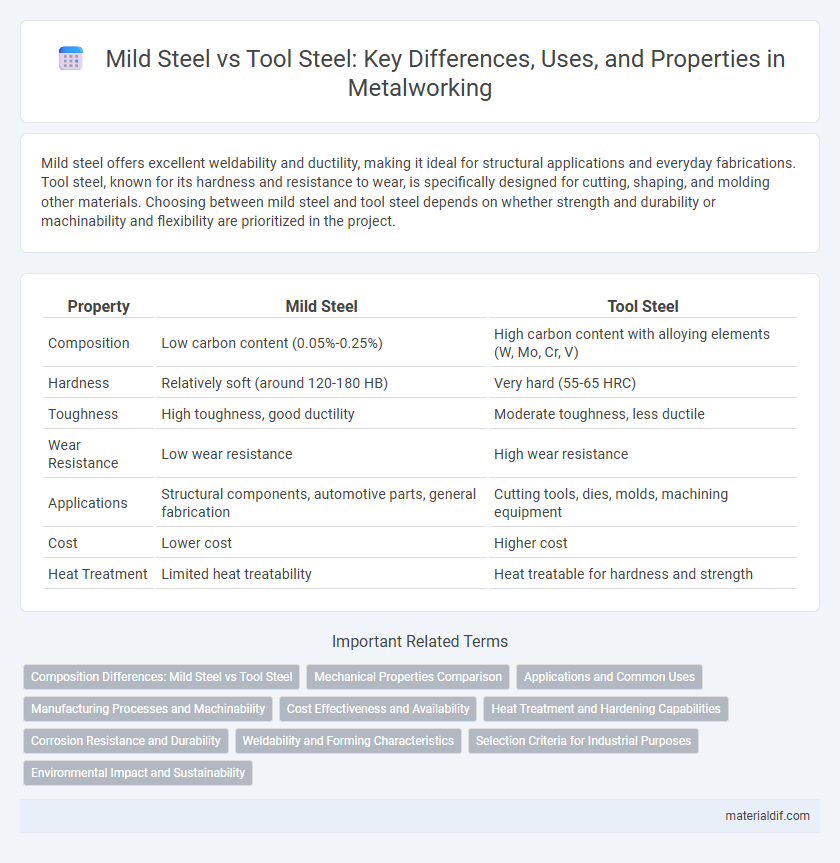

Mild steel offers excellent weldability and ductility, making it ideal for structural applications and everyday fabrications. Tool steel, known for its hardness and resistance to wear, is specifically designed for cutting, shaping, and molding other materials. Choosing between mild steel and tool steel depends on whether strength and durability or machinability and flexibility are prioritized in the project.

Table of Comparison

| Property | Mild Steel | Tool Steel |

|---|---|---|

| Composition | Low carbon content (0.05%-0.25%) | High carbon content with alloying elements (W, Mo, Cr, V) |

| Hardness | Relatively soft (around 120-180 HB) | Very hard (55-65 HRC) |

| Toughness | High toughness, good ductility | Moderate toughness, less ductile |

| Wear Resistance | Low wear resistance | High wear resistance |

| Applications | Structural components, automotive parts, general fabrication | Cutting tools, dies, molds, machining equipment |

| Cost | Lower cost | Higher cost |

| Heat Treatment | Limited heat treatability | Heat treatable for hardness and strength |

Composition Differences: Mild Steel vs Tool Steel

Mild steel primarily contains 0.05% to 0.25% carbon, making it softer and more ductile, whereas tool steel has a higher carbon content ranging from 0.5% to 1.5%, combined with alloying elements like tungsten, chromium, and vanadium to enhance hardness and wear resistance. The presence of these alloying elements in tool steel significantly improves its heat resistance and toughness compared to mild steel's simpler composition dominated by iron and low carbon. These compositional differences dictate their applications, with mild steel favored for structural use and tool steel chosen for cutting tools and high-stress components.

Mechanical Properties Comparison

Mild steel exhibits lower hardness and tensile strength, typically ranging from 400 to 550 MPa, making it highly ductile and easy to weld. Tool steel offers superior mechanical properties with hardness values often exceeding 60 HRC and tensile strength above 1000 MPa, enabling exceptional wear resistance and toughness for cutting and forming applications. The enhanced carbon content and alloying elements in tool steel result in superior impact resistance and thermal stability compared to mild steel.

Applications and Common Uses

Mild steel is widely used in construction, automotive parts, and structural applications due to its ductility and weldability, making it ideal for manufacturing pipes, sheets, and wire products. Tool steel, known for its hardness and resistance to wear and deformation, is predominantly applied in cutting tools, dies, molds, and machine components requiring high strength and durability. The choice between mild steel and tool steel depends on the application's requirement for flexibility versus hardness and abrasion resistance.

Manufacturing Processes and Machinability

Mild steel undergoes simpler manufacturing processes such as hot rolling and annealing, enabling cost-effective mass production, while tool steel requires specialized heat treatments like quenching and tempering to enhance hardness and wear resistance. The machinability of mild steel is generally higher due to its lower carbon content and softer microstructure, allowing faster cutting speeds and reduced tool wear. In contrast, tool steel's high hardness and alloying elements result in lower machinability, necessitating the use of advanced cutting tools and slower machining parameters to achieve precise dimensions.

Cost Effectiveness and Availability

Mild steel is significantly more cost-effective than tool steel due to its lower carbon content and simpler production process, making it ideal for large-scale manufacturing and budget-sensitive projects. Its widespread availability in standard forms like sheets, plates, and bars ensures easy procurement and reduced lead times compared to tool steel, which is more expensive and often requires specialized alloying elements. While tool steel offers superior hardness and wear resistance for cutting and shaping tools, mild steel remains the preferred choice when affordability and material availability are critical.

Heat Treatment and Hardening Capabilities

Mild steel typically undergoes annealing and normalizing to relieve stress and improve machinability but lacks significant hardening capabilities due to its low carbon content, making it unsuitable for applications requiring high wear resistance. Tool steel contains higher carbon and alloying elements such as chromium, vanadium, and molybdenum, enabling advanced heat treatment processes like quenching and tempering that achieve superior hardness and toughness. The enhanced hardening capabilities of tool steel result in improved performance for cutting, shaping, and forming tools under high-stress conditions.

Corrosion Resistance and Durability

Mild steel exhibits lower corrosion resistance due to its higher carbon content and lack of alloying elements, making it more susceptible to rust and wear in harsh environments. Tool steel, enhanced with elements like chromium, vanadium, and molybdenum, provides superior corrosion resistance and exceptional durability, ideal for high-stress applications. The toughness and hardness of tool steel enable longer service life and withstand impact and abrasion better than mild steel.

Weldability and Forming Characteristics

Mild steel offers superior weldability due to its low carbon content, allowing easy fusion without cracking, whereas tool steel requires preheating and controlled cooling to prevent brittleness during welding. Forming characteristics of mild steel are favorable, exhibiting high ductility and ease of machining, while tool steel's hardness and wear resistance reduce its ability to be formed without specialized processes. Selecting between mild steel and tool steel depends on balancing ease of fabrication against performance requirements in tooling applications.

Selection Criteria for Industrial Purposes

Mild steel is preferred for applications requiring high ductility, weldability, and cost-effectiveness, making it ideal for structural components and automotive bodies. Tool steel is selected for its superior hardness, wear resistance, and ability to retain a sharp edge, essential in cutting, shaping, and molding tools. Industrial selection depends on the balance between mechanical properties, machinability, and service environment demands, with mild steel favored for general fabrication and tool steel for precision tooling.

Environmental Impact and Sustainability

Mild steel has a lower carbon content, making it easier to recycle and requiring less energy during production compared to tool steel, which contains higher alloying elements that complicate recycling processes. The environmental impact of mild steel is generally lower due to reduced emissions and energy consumption in its manufacturing cycle. Tool steel's durability and wear resistance contribute to longer product lifespans, which can offset its higher initial environmental cost through extended use and reduced need for frequent replacements.

Mild Steel vs Tool Steel Infographic

materialdif.com

materialdif.com