Sintering involves compacting metal powders at high temperatures below their melting point to create solid parts with controlled porosity and fine microstructures. Forging, on the other hand, uses compressive forces applied to heated metal billets to produce components with enhanced mechanical properties and grain alignment. While sintering is ideal for complex shapes and powder metallurgy, forging excels in strength and toughness for critical structural applications.

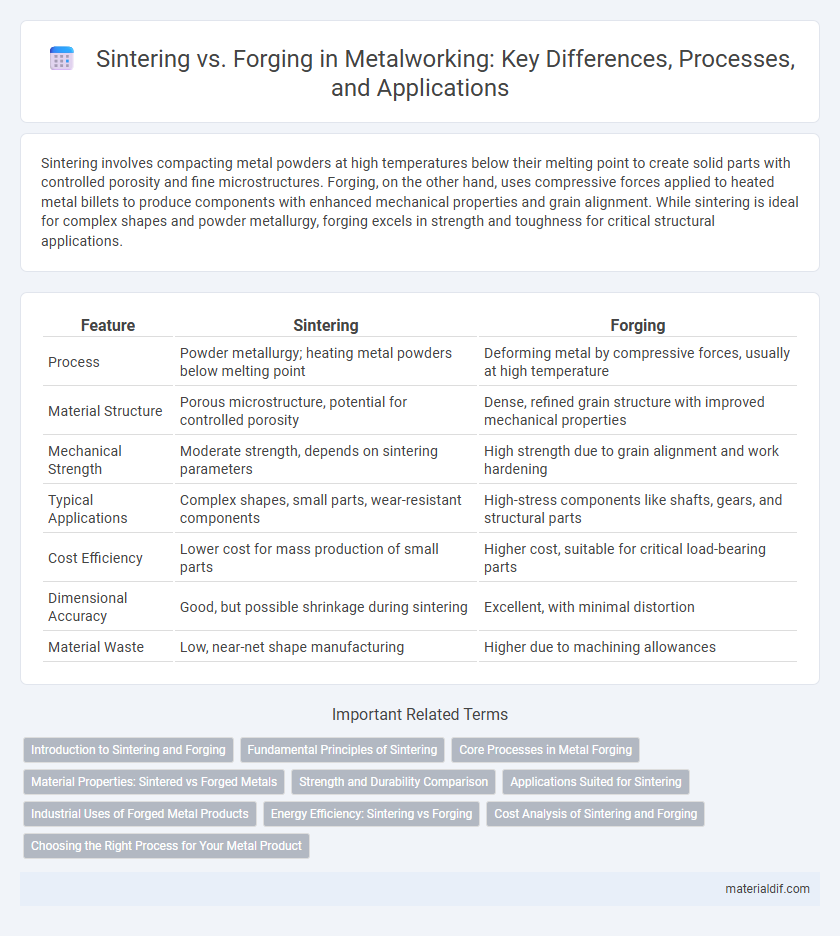

Table of Comparison

| Feature | Sintering | Forging |

|---|---|---|

| Process | Powder metallurgy; heating metal powders below melting point | Deforming metal by compressive forces, usually at high temperature |

| Material Structure | Porous microstructure, potential for controlled porosity | Dense, refined grain structure with improved mechanical properties |

| Mechanical Strength | Moderate strength, depends on sintering parameters | High strength due to grain alignment and work hardening |

| Typical Applications | Complex shapes, small parts, wear-resistant components | High-stress components like shafts, gears, and structural parts |

| Cost Efficiency | Lower cost for mass production of small parts | Higher cost, suitable for critical load-bearing parts |

| Dimensional Accuracy | Good, but possible shrinkage during sintering | Excellent, with minimal distortion |

| Material Waste | Low, near-net shape manufacturing | Higher due to machining allowances |

Introduction to Sintering and Forging

Sintering is a powder metallurgy process where metal powders are heated below their melting point to bond particles into a solid mass, enhancing material properties and producing complex shapes with minimal waste. Forging involves deforming metal under high pressure, typically at elevated temperatures, to improve strength through grain refinement and directional flow. Both methods optimize metal performance, but sintering excels in precision and material utilization, while forging delivers superior mechanical strength and toughness.

Fundamental Principles of Sintering

Sintering is a powder metallurgy process where metal particles are heated below their melting point to bond and form a solid mass, emphasizing diffusion mechanisms for particle cohesion. This process relies on atomic diffusion that reduces porosity and increases strength by neck growth between particles without melting the base material. Unlike forging, which deforms solid metal through compressive forces, sintering achieves densification through controlled thermal energy and material transport phenomena.

Core Processes in Metal Forging

Metal forging core processes involve heating metal to a malleable state before shaping it with compressive forces, enhancing grain structure and mechanical properties. Unlike sintering, which fuses powdered metal particles through heat below melting point, forging ensures superior strength and durability by deforming solid metal billets. Key forging methods include open-die, closed-die, and impression-die forging, each optimizing microstructure and reducing porosity for critical industrial applications.

Material Properties: Sintered vs Forged Metals

Sintered metals exhibit increased porosity, resulting in lower density and reduced mechanical strength compared to forged metals, which have a more uniform and compact grain structure that enhances tensile strength and toughness. Forging aligns the metal's grain flow, improving fatigue resistance and impact strength, whereas sintering may retain residual porosity that can act as stress concentrators. The choice between sintering and forging significantly influences hardness, ductility, and structural integrity based on the intended application and performance requirements.

Strength and Durability Comparison

Sintering enhances metal strength through controlled particle bonding at lower temperatures, resulting in uniform microstructures and optimized fatigue resistance. Forging generates superior durability by deforming metal under high pressure, aligning grain flow and eliminating internal voids for exceptional toughness. Both processes yield strong metals, but forging typically achieves higher tensile strength and impact resistance critical for demanding applications.

Applications Suited for Sintering

Sintering is especially suited for producing complex, high-precision metal components with intricate geometries that are difficult to achieve through forging. Industries such as automotive, aerospace, and electronics rely on sintering to manufacture porous parts, filters, and magnetic components with controlled porosity and precise dimensional tolerances. This powder metallurgy process excels in mass production of small to medium-sized parts with consistent quality and reduced material waste.

Industrial Uses of Forged Metal Products

Forged metal products are extensively used in industries requiring high-strength components such as automotive, aerospace, and heavy machinery due to their superior mechanical properties and fatigue resistance. The forging process enhances the grain structure, resulting in improved durability and reliability for critical parts like crankshafts, connecting rods, and turbine blades. Industrial applications favor forged metals for their ability to withstand extreme stresses and harsh operating conditions compared to sintered alternatives.

Energy Efficiency: Sintering vs Forging

Sintering consumes less energy compared to forging due to lower temperature requirements and shorter processing times, making it ideal for producing complex metal parts with minimal energy input. Forging demands higher energy because it involves heating metals to very high temperatures and applying substantial mechanical force, which increases overall power consumption. Energy efficiency in sintering contributes to reduced production costs and environmental impact, especially in mass manufacturing of powder metallurgy components.

Cost Analysis of Sintering and Forging

Sintering offers a cost-effective advantage due to lower material waste and reduced energy consumption compared to forging, which requires high capital investment in heavy machinery and extensive labor. Forging incurs higher operational costs from prolonged heating cycles and machining processes, but it delivers superior mechanical properties that can reduce long-term maintenance expenses. Evaluating the total cost of ownership reveals sintering as optimal for mass production of complex shapes, while forging suits applications demanding enhanced structural integrity despite increased initial expenses.

Choosing the Right Process for Your Metal Product

Selecting the right metal forming process depends on the desired product characteristics and application requirements. Sintering excels in producing complex shapes with fine microstructures and minimal material waste, ideal for powdered metal components used in automotive and aerospace industries. Forging offers superior mechanical strength and toughness by refining grain structures, making it suitable for high-stress parts such as crankshafts and connecting rods in heavy machinery.

Sintering vs Forging Infographic

materialdif.com

materialdif.com