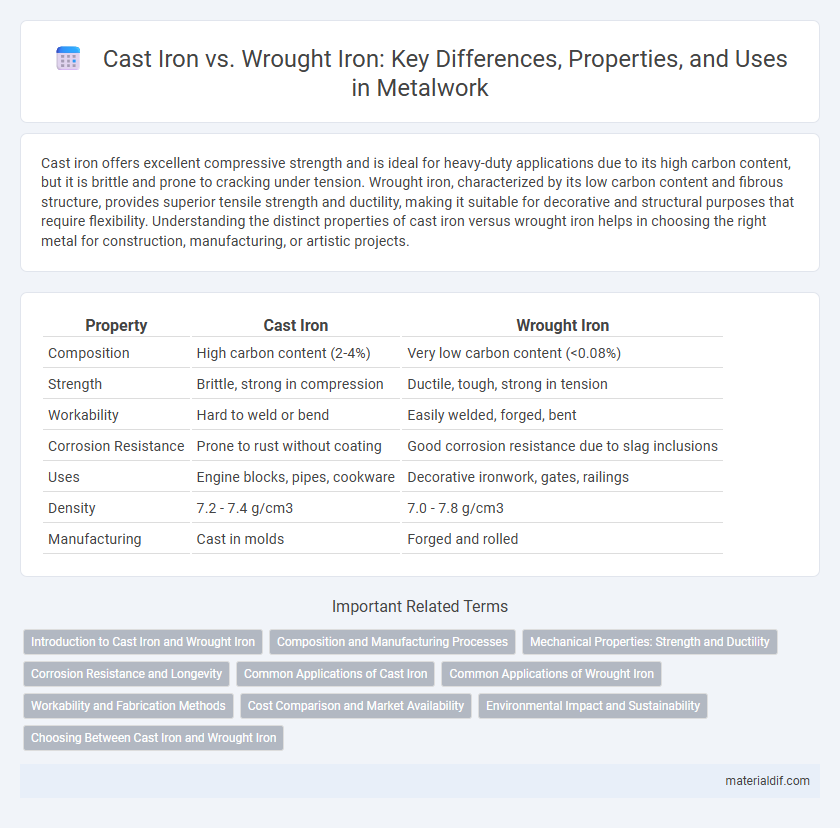

Cast iron offers excellent compressive strength and is ideal for heavy-duty applications due to its high carbon content, but it is brittle and prone to cracking under tension. Wrought iron, characterized by its low carbon content and fibrous structure, provides superior tensile strength and ductility, making it suitable for decorative and structural purposes that require flexibility. Understanding the distinct properties of cast iron versus wrought iron helps in choosing the right metal for construction, manufacturing, or artistic projects.

Table of Comparison

| Property | Cast Iron | Wrought Iron |

|---|---|---|

| Composition | High carbon content (2-4%) | Very low carbon content (<0.08%) |

| Strength | Brittle, strong in compression | Ductile, tough, strong in tension |

| Workability | Hard to weld or bend | Easily welded, forged, bent |

| Corrosion Resistance | Prone to rust without coating | Good corrosion resistance due to slag inclusions |

| Uses | Engine blocks, pipes, cookware | Decorative ironwork, gates, railings |

| Density | 7.2 - 7.4 g/cm3 | 7.0 - 7.8 g/cm3 |

| Manufacturing | Cast in molds | Forged and rolled |

Introduction to Cast Iron and Wrought Iron

Cast iron is a brittle, hard metal alloy primarily composed of iron, carbon (2-4%), and silicon, known for its excellent compressive strength and wear resistance. Wrought iron contains less carbon (typically less than 0.08%), making it malleable, ductile, and easy to weld or forge, favored for decorative and structural applications. These fundamental differences in carbon content and microstructure distinguish cast iron's rigidity from wrought iron's malleability.

Composition and Manufacturing Processes

Cast iron contains a high carbon content, typically 2-4%, combined with silicon, manganese, and trace elements, produced by melting iron and casting it into molds. Wrought iron has a much lower carbon content, usually less than 0.08%, with fibrous inclusions of slag that enhance its toughness, formed through repeated heating and mechanical working such as hammering and rolling. The manufacturing process of cast iron emphasizes melting and casting, while wrought iron is characterized by forging and shaping without melting, resulting in distinct structural and mechanical properties.

Mechanical Properties: Strength and Ductility

Cast iron exhibits high compressive strength but low tensile strength and ductility due to its brittle carbon-rich microstructure, making it prone to cracking under tension. Wrought iron offers moderate tensile strength combined with excellent ductility and toughness, owing to its fibrous slag inclusions that enhance deformation without fracture. The superior ductility of wrought iron allows it to absorb impact and deform plastically, whereas cast iron's brittleness limits its use to applications requiring hardness and wear resistance.

Corrosion Resistance and Longevity

Cast iron offers moderate corrosion resistance due to its carbon content forming a protective oxide layer, but it is more brittle and prone to cracking over time. Wrought iron exhibits superior corrosion resistance thanks to its fibrous slag inclusions that improve durability and oxidation resistance, enhancing its longevity in outdoor environments. Consequently, wrought iron generally outlasts cast iron in terms of durability and rust prevention, making it ideal for fences and outdoor structures.

Common Applications of Cast Iron

Cast iron is widely used in construction for pipes, manhole covers, and architectural elements due to its excellent compressive strength and durability. It also serves critical roles in automotive components like engine blocks and brake rotors, benefiting from its wear resistance and vibration dampening properties. Additionally, cast iron cookware remains popular for heat retention and even cooking performance.

Common Applications of Wrought Iron

Wrought iron is widely used in decorative gates, railings, and furniture due to its malleability and corrosion resistance. Its fibrous structure makes it ideal for ornamental work requiring intricate designs and longevity in outdoor environments. Unlike cast iron, wrought iron is favored for applications demanding flexibility and weldability without compromising strength.

Workability and Fabrication Methods

Cast iron offers limited workability due to its high carbon content, making it brittle and challenging to weld or forge, thus requiring casting as the primary fabrication method. Wrought iron features low carbon content and fibrous inclusions, providing excellent malleability and ductility, which allows it to be easily forged, rolled, or welded. Fabricators prefer wrought iron for intricate designs and structural applications because it withstands mechanical deformation without cracking, unlike cast iron.

Cost Comparison and Market Availability

Cast iron is generally more affordable than wrought iron due to its easier production process and abundant raw materials. Wrought iron commands a higher price because of its labor-intensive forging process and limited supply, making it less available in the market. Cast iron products dominate mass-market availability, while wrought iron is often reserved for premium custom applications.

Environmental Impact and Sustainability

Cast iron production generates higher carbon emissions due to its coke-based smelting process, contributing significantly to air pollution and greenhouse gases. Wrought iron, traditionally made using charcoal and wrought methods, has a lower environmental footprint but is less commonly produced today, reducing its sustainability advantages. Recycling wrought iron consumes less energy and lowers waste, making it a more sustainable option in comparison to cast iron's energy-intensive manufacturing.

Choosing Between Cast Iron and Wrought Iron

Choosing between cast iron and wrought iron depends on the application's strength and durability requirements; cast iron offers superior compressive strength and excellent wear resistance, making it ideal for heavy-duty structures and cookware. Wrought iron, characterized by its fibrous structure and malleability, excels in ornamental work, fencing, and applications requiring flexibility and impact resistance. Understanding the mechanical properties and corrosion behavior of both metals ensures optimal performance and longevity in construction or decorative projects.

Cast Iron vs Wrought Iron Infographic

materialdif.com

materialdif.com