Machined finish on metal offers a smoother, more precise surface achieved through cutting processes, enhancing both aesthetics and functional fit. In contrast, mill finish is the raw, unrefined texture resulting directly from the metal rolling process, often exhibiting a rougher, more industrial appearance. Choosing between machined and mill finishes depends on the desired surface quality, application requirements, and cost considerations.

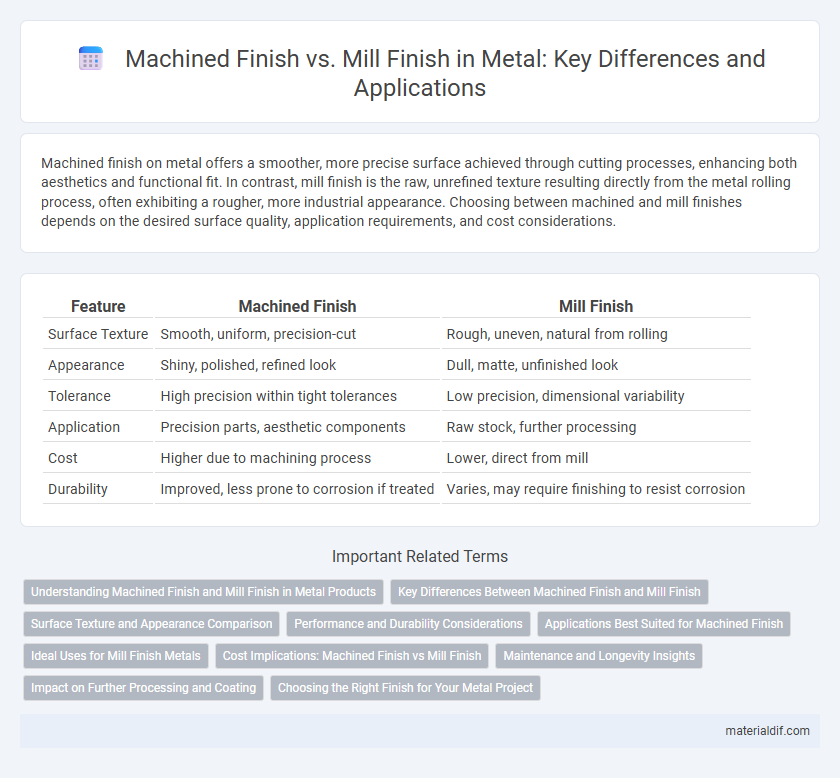

Table of Comparison

| Feature | Machined Finish | Mill Finish |

|---|---|---|

| Surface Texture | Smooth, uniform, precision-cut | Rough, uneven, natural from rolling |

| Appearance | Shiny, polished, refined look | Dull, matte, unfinished look |

| Tolerance | High precision within tight tolerances | Low precision, dimensional variability |

| Application | Precision parts, aesthetic components | Raw stock, further processing |

| Cost | Higher due to machining process | Lower, direct from mill |

| Durability | Improved, less prone to corrosion if treated | Varies, may require finishing to resist corrosion |

Understanding Machined Finish and Mill Finish in Metal Products

Machined finish in metal products involves precise cutting and surface treatment to achieve smoothness and dimensional accuracy, enhancing both aesthetic appeal and functional performance. Mill finish refers to the surface texture produced directly by the rolling or extrusion process, typically rougher and less refined than machined finishes, often requiring further processing for applications needing finer surfaces. Understanding the differences between machined and mill finishes is crucial for selecting the appropriate surface treatment to meet specific engineering and design requirements.

Key Differences Between Machined Finish and Mill Finish

Machined finish refers to the surface texture achieved through precision cutting or grinding, resulting in a smoother, more uniform appearance and tighter dimensional tolerances compared to mill finish. Mill finish is the raw, unprocessed surface of metal directly from the rolling mill, characterized by its rough, uneven texture and higher variability in surface flatness. The key differences lie in surface roughness, aesthetic quality, and suitability for applications requiring enhanced precision and visual appeal.

Surface Texture and Appearance Comparison

Machined finish metal exhibits a smooth, finely detailed surface texture achieved through precise cutting tools, resulting in a polished and uniform appearance ideal for aesthetic applications. Mill finish metal retains the rough, unfinished texture from the rolling or extrusion process, showcasing visible tool marks and imperfections with a matte, industrial look. The choice between machined and mill finish directly impacts corrosion resistance and paint adhesion, as the smoother machined surface provides better protection and coating performance.

Performance and Durability Considerations

Machined finish metal surfaces offer enhanced performance through tighter tolerances and smoother textures, reducing friction and wear in mechanical applications. Mill finish metals, while more cost-effective, typically have rougher surfaces that can harbor contaminants and reduce corrosion resistance, impacting long-term durability. Selecting machined finishes improves fatigue strength and resistance to environmental factors, making them ideal for high-stress or precision components.

Applications Best Suited for Machined Finish

Machined finish metal surfaces offer superior precision and smoothness, making them ideal for high-performance applications such as aerospace components, medical devices, and automotive parts where tight tolerances and aesthetic quality are critical. These finishes enhance corrosion resistance and improve wear characteristics, benefiting environments requiring durability and cleanliness. Industries requiring precise mating surfaces, enhanced fatigue strength, and reduced friction commonly choose machined finishes over mill finishes for optimal functionality.

Ideal Uses for Mill Finish Metals

Mill finish metals are ideal for applications requiring cost-effective material with a raw, untreated surface that maintains structural integrity. Common uses include fabrication processes where the metal will undergo further machining, welding, or painting, as the mill finish provides a uniform base without additional processing costs. These metals are frequently employed in construction, automotive frames, and industrial equipment where surface appearance is secondary to strength and durability.

Cost Implications: Machined Finish vs Mill Finish

Machined finish metal surfaces require additional processing time and precision, leading to higher labor and equipment costs compared to mill finish, which is the natural state after rolling with minimal surface treatment. Machined finishes provide tighter dimensional tolerances and improved surface quality, often justifying the extra expense in applications demanding aesthetics or performance. Mill finish is cost-effective for structural or non-visible parts where appearance and surface smoothness are less critical, offering savings in manufacturing budgets.

Maintenance and Longevity Insights

Machined finish metal surfaces offer enhanced maintenance ease due to their smooth texture, reducing dirt accumulation and corrosion risk compared to rough mill finish surfaces. Mill finish metals, typically untreated and porous, require more frequent cleaning and protective coatings to prevent oxidation and surface degradation. The longer lifespan of machined finishes results from their precision surface treatment that minimizes wear and extends material durability under varying environmental conditions.

Impact on Further Processing and Coating

Machined finish provides a smoother, more uniform surface that enhances adhesion and durability of subsequent coatings, reducing the need for extensive surface preparation. Mill finish, typically rougher and uneven from initial metal rolling, often requires additional sanding or grinding to ensure coating compatibility and to prevent premature corrosion. Choosing machined finish can streamline downstream processes such as painting or plating, improving overall coating performance and longevity.

Choosing the Right Finish for Your Metal Project

Machined finish offers precise surface texture and enhanced durability by removing excess material through cutting tools, ideal for components requiring tight tolerances and aesthetic appeal. Mill finish, the natural state of metal after rolling, features a rougher surface suitable for structural applications where minimal processing is needed. Selecting the right finish depends on project requirements such as surface smoothness, functional performance, and cost efficiency.

Machined Finish vs Mill Finish Infographic

materialdif.com

materialdif.com