TIG welding provides precise, high-quality welds ideal for thin metals and intricate projects, offering superior control over heat and filler material compared to MIG welding. MIG welding excels in speed and ease of use, making it suitable for thicker metals and large-scale fabrication with consistent weld strength. Understanding the specific requirements of a project ensures the optimal choice between TIG's precision and MIG's efficiency.

Table of Comparison

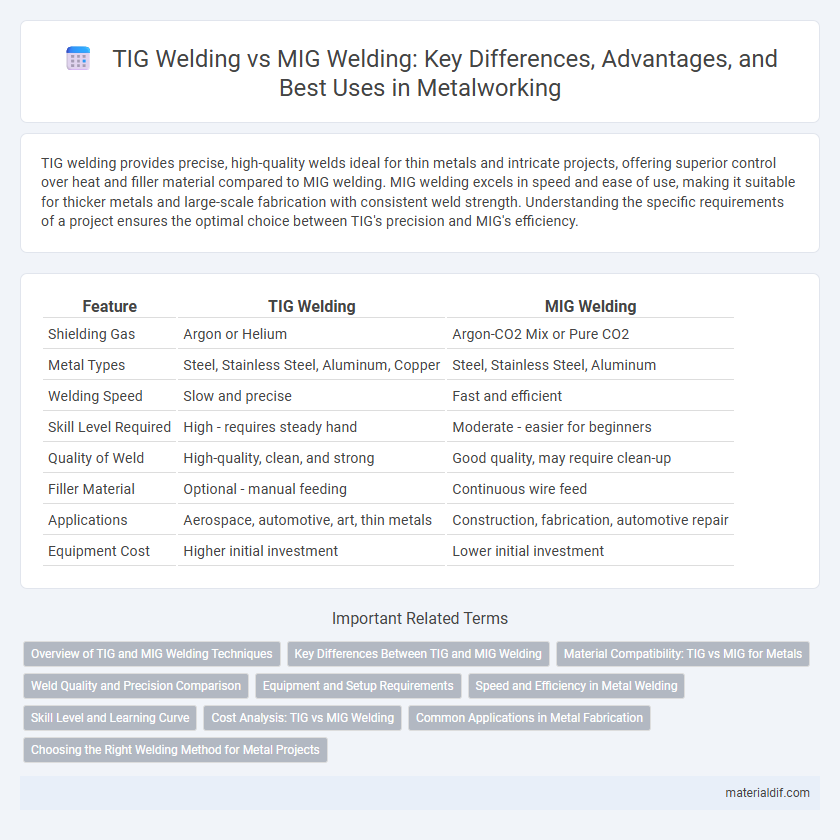

| Feature | TIG Welding | MIG Welding |

|---|---|---|

| Shielding Gas | Argon or Helium | Argon-CO2 Mix or Pure CO2 |

| Metal Types | Steel, Stainless Steel, Aluminum, Copper | Steel, Stainless Steel, Aluminum |

| Welding Speed | Slow and precise | Fast and efficient |

| Skill Level Required | High - requires steady hand | Moderate - easier for beginners |

| Quality of Weld | High-quality, clean, and strong | Good quality, may require clean-up |

| Filler Material | Optional - manual feeding | Continuous wire feed |

| Applications | Aerospace, automotive, art, thin metals | Construction, fabrication, automotive repair |

| Equipment Cost | Higher initial investment | Lower initial investment |

Overview of TIG and MIG Welding Techniques

TIG welding uses a non-consumable tungsten electrode to create precise, high-quality welds ideal for thin metals and intricate work, offering superior control over heat and filler material. MIG welding employs a consumable wire electrode fed continuously through a welding gun, making it efficient for faster, larger-scale projects and thicker metals. Both techniques serve distinct industrial applications, with TIG favored in aerospace and automotive industries for detail and MIG preferred in construction and manufacturing for speed.

Key Differences Between TIG and MIG Welding

TIG welding uses a non-consumable tungsten electrode and provides greater precision, making it ideal for thin metals and intricate work, while MIG welding employs a consumable wire electrode fed continuously, allowing faster welding on thicker materials. TIG welding requires a shielding gas like argon and produces cleaner welds with minimal spatter, whereas MIG welding uses shielding gases such as argon-CO2 mixes and is better suited for high-production environments due to its speed. The key differences between TIG and MIG welding include electrode type, welding speed, application suitability, and finish quality, influencing their selection based on project requirements.

Material Compatibility: TIG vs MIG for Metals

TIG welding excels in welding thin metals like stainless steel, aluminum, and copper due to its precise heat control and clean welds, offering superior compatibility with reactive and non-ferrous metals. MIG welding is more versatile for thicker metals and is ideal for ferrous metals such as carbon steel and low alloy steel, providing faster welds with greater deposition rates. Choosing between TIG and MIG welding depends on the metal type, thickness, and the required weld quality for the specific application.

Weld Quality and Precision Comparison

TIG welding offers superior weld quality and precision due to its controlled heat input and ability to produce clean, high-strength welds with minimal spatter, making it ideal for thin metals and critical applications. MIG welding provides faster deposition rates but may result in less precise welds with more spatter, suitable for thicker materials and production environments. The choice between TIG and MIG welding depends on the required weld finish, material type, and project specifications.

Equipment and Setup Requirements

TIG welding requires a tungsten electrode, a constant current power supply, and an inert gas such as argon for shielding, leading to a more intricate and precise equipment setup compared to MIG welding. MIG welding uses a continuously fed wire electrode and a constant voltage power source with a shielding gas mix like argon and CO2, making its setup simpler and faster to configure for production environments. The equipment differences impact the portability, maintenance, and skill level required for each welding process.

Speed and Efficiency in Metal Welding

TIG welding offers precise control and is ideal for thin metals but generally works slower due to its manual process. MIG welding excels in speed and efficiency, making it suitable for thicker metals and large-scale projects by continuously feeding wire and producing less downtime. For high-speed production tasks, MIG welding is typically the preferred choice due to its rapid application and lower skill requirements.

Skill Level and Learning Curve

TIG welding demands a higher skill level due to its precise control of heat and filler material, making it ideal for detailed and thin metalwork but requiring extensive practice to master. MIG welding offers a gentler learning curve with easier operation and faster welding speeds, suitable for beginners and high-production environments. The choice between TIG and MIG welding often depends on the operator's experience and the complexity of the welding task.

Cost Analysis: TIG vs MIG Welding

TIG welding generally incurs higher costs due to slower welding speeds, specialized gas requirements, and more expensive equipment compared to MIG welding. MIG welding offers cost-effectiveness with faster deposition rates, lower labor expenses, and simpler shielding gas setups, making it ideal for high-volume production. Evaluating project budgets, weld quality needs, and material thickness is crucial for determining the most economical welding process.

Common Applications in Metal Fabrication

TIG welding is commonly used for precision work on thin metals like stainless steel and aluminum, offering clean, high-quality welds ideal for aerospace and automotive industries. MIG welding excels in faster, thicker metal fabrication, making it popular in construction, shipbuilding, and heavy equipment manufacturing. Both methods serve critical roles in metal fabrication, with TIG chosen for detailed, visually appealing joints and MIG preferred for rapid production and structural strength.

Choosing the Right Welding Method for Metal Projects

Tig welding offers precise control and is ideal for thin metals and intricate projects, providing high-quality, clean welds with minimal spatter. Mig welding excels in speed and ease of use, making it suitable for thicker metals and larger-scale fabrication tasks where efficiency is crucial. Selecting between Tig and Mig welding depends on factors like metal type, project complexity, and desired weld strength, ensuring the method aligns with specific metalworking requirements.

Tig Welding vs Mig Welding Infographic

materialdif.com

materialdif.com