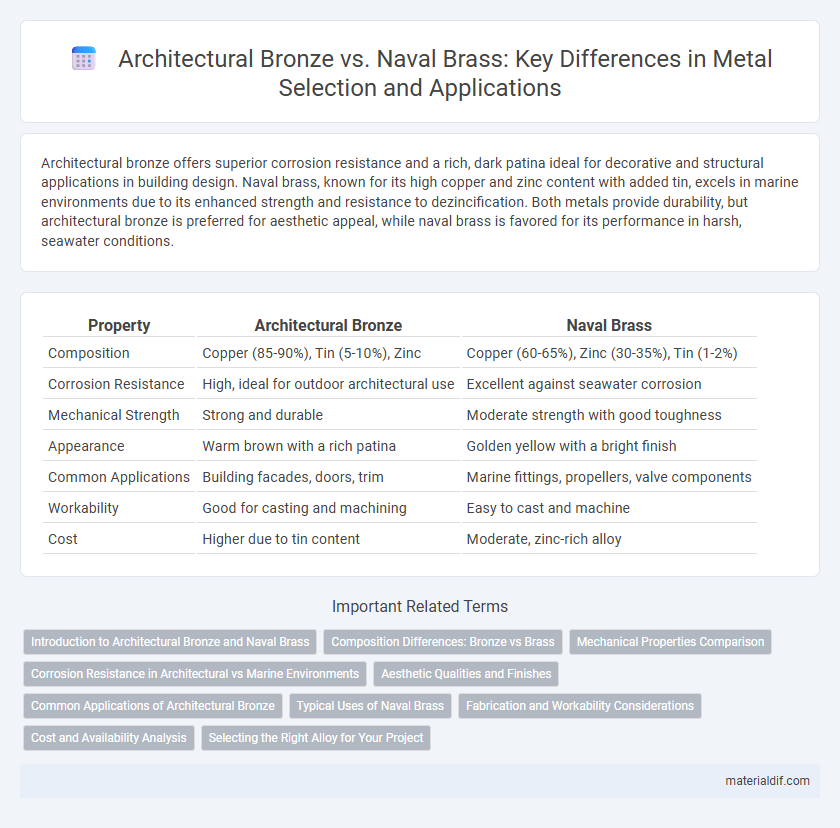

Architectural bronze offers superior corrosion resistance and a rich, dark patina ideal for decorative and structural applications in building design. Naval brass, known for its high copper and zinc content with added tin, excels in marine environments due to its enhanced strength and resistance to dezincification. Both metals provide durability, but architectural bronze is preferred for aesthetic appeal, while naval brass is favored for its performance in harsh, seawater conditions.

Table of Comparison

| Property | Architectural Bronze | Naval Brass |

|---|---|---|

| Composition | Copper (85-90%), Tin (5-10%), Zinc | Copper (60-65%), Zinc (30-35%), Tin (1-2%) |

| Corrosion Resistance | High, ideal for outdoor architectural use | Excellent against seawater corrosion |

| Mechanical Strength | Strong and durable | Moderate strength with good toughness |

| Appearance | Warm brown with a rich patina | Golden yellow with a bright finish |

| Common Applications | Building facades, doors, trim | Marine fittings, propellers, valve components |

| Workability | Good for casting and machining | Easy to cast and machine |

| Cost | Higher due to tin content | Moderate, zinc-rich alloy |

Introduction to Architectural Bronze and Naval Brass

Architectural bronze is a durable alloy primarily composed of copper, zinc, and small amounts of lead, designed for aesthetic appeal and corrosion resistance in building applications. Naval brass, containing copper, zinc, and tin, is specifically formulated for marine environments, offering enhanced strength and resistance to saltwater corrosion. Both metals serve distinct roles in construction and marine hardware due to their tailored compositions and properties.

Composition Differences: Bronze vs Brass

Architectural bronze primarily consists of copper, with about 5-12% tin, which enhances its hardness and corrosion resistance suitable for decorative and structural applications. Naval brass, on the other hand, includes roughly 60-70% copper, 30-40% zinc, and small amounts of tin and iron to improve resistance against saltwater corrosion and biofouling. The key compositional difference lies in the tin content, higher in architectural bronze for durability, while naval brass relies more on zinc for strength and performance in marine environments.

Mechanical Properties Comparison

Architectural bronze exhibits higher tensile strength and greater hardness compared to naval brass, making it more suitable for structural applications requiring durability and wear resistance. Naval brass offers superior corrosion resistance and better machinability, especially in marine environments, due to its higher zinc and tin content. The choice between architectural bronze and naval brass depends on balancing mechanical strength requirements against environmental exposure and fabrication needs.

Corrosion Resistance in Architectural vs Marine Environments

Architectural bronze exhibits superior corrosion resistance in urban and industrial environments due to its high copper and tin content, which forms a durable oxide layer protecting against pollutants and weathering. Naval brass, containing zinc and small amounts of lead, is specifically engineered for marine environments, offering excellent resistance to seawater corrosion and biofouling. While architectural bronze performs well against atmospheric corrosion, naval brass is optimized for submerged or splash zone applications where chloride exposure is intense.

Aesthetic Qualities and Finishes

Architectural bronze offers a rich, warm patina that enhances building facades and interior design with its deep, chocolate-brown hues and smooth, matte finishes. Naval brass, composed primarily of copper and zinc, features a brighter, yellow-gold appearance with a high polish that resists tarnishing, making it ideal for decorative elements exposed to harsh marine environments. Both metals provide durable, aesthetically distinct options, with architectural bronze favored for its elegant, weathering characteristics, and naval brass prized for its reflective brilliance and corrosion resistance.

Common Applications of Architectural Bronze

Architectural bronze is primarily used in high-end architectural elements such as doors, window frames, and decorative trim due to its corrosion resistance and elegant appearance. It is favored for exterior building components and interior design features, providing durability and a timeless aesthetic. Unlike naval brass, which is typically used in marine environments and hardware, architectural bronze is selected for its strength and visual appeal in construction and ornamental applications.

Typical Uses of Naval Brass

Naval brass is primarily used in marine environments due to its excellent corrosion resistance and strength, making it ideal for ship fittings, propellers, and seawater piping systems. Its high copper content combined with zinc and small amounts of tin allows it to withstand prolonged exposure to saltwater without significant degradation. This alloy's durability and resistance to dezincification also make it suitable for valves, pumps, and other components in offshore and underwater applications.

Fabrication and Workability Considerations

Architectural bronze offers superior corrosion resistance and ease of machining, making it ideal for intricate fabrications and detailed ornamental work. Naval brass, with its higher zinc and tin content, provides excellent strength and toughness but presents more challenges during machining due to its tendency to work-harden. Choosing between these alloys depends on prioritizing either fabrication complexity or mechanical durability in architectural metalwork projects.

Cost and Availability Analysis

Architectural bronze generally commands a higher price than naval brass due to its premium copper and tin composition, which offers enhanced durability and corrosion resistance. Naval brass, an alloy of copper, zinc, and small amounts of tin, is more readily available and cost-effective, making it a preferred choice for budget-conscious projects. The broader supply chain and established manufacturing processes for naval brass contribute to its lower market price and quicker lead times compared to architectural bronze.

Selecting the Right Alloy for Your Project

Architectural bronze offers superior corrosion resistance and a rich, warm patina ideal for decorative elements and structural applications in urban environments. Naval brass, containing higher zinc content and tin, excels in marine settings with exceptional resistance to saltwater corrosion and biofouling. Choosing between architectural bronze and naval brass depends on environmental exposure, aesthetic preference, and mechanical properties required for longevity and performance.

Architectural Bronze vs Naval Brass Infographic

materialdif.com

materialdif.com