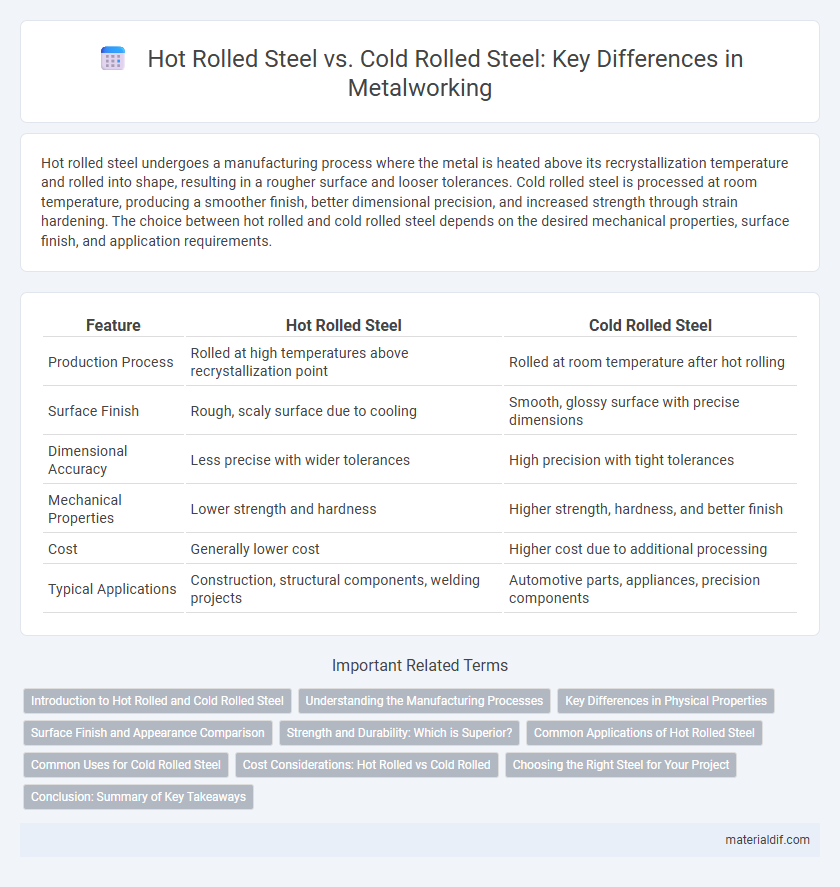

Hot rolled steel undergoes a manufacturing process where the metal is heated above its recrystallization temperature and rolled into shape, resulting in a rougher surface and looser tolerances. Cold rolled steel is processed at room temperature, producing a smoother finish, better dimensional precision, and increased strength through strain hardening. The choice between hot rolled and cold rolled steel depends on the desired mechanical properties, surface finish, and application requirements.

Table of Comparison

| Feature | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Production Process | Rolled at high temperatures above recrystallization point | Rolled at room temperature after hot rolling |

| Surface Finish | Rough, scaly surface due to cooling | Smooth, glossy surface with precise dimensions |

| Dimensional Accuracy | Less precise with wider tolerances | High precision with tight tolerances |

| Mechanical Properties | Lower strength and hardness | Higher strength, hardness, and better finish |

| Cost | Generally lower cost | Higher cost due to additional processing |

| Typical Applications | Construction, structural components, welding projects | Automotive parts, appliances, precision components |

Introduction to Hot Rolled and Cold Rolled Steel

Hot rolled steel undergoes processing at high temperatures exceeding 1700degF, resulting in a rough surface and less precise dimensions ideal for structural applications. Cold rolled steel is produced by further processing hot rolled steel at room temperature, enhancing its surface finish and dimensional accuracy for use in automotive and appliance manufacturing. Both types offer distinct mechanical properties suited to varying industry requirements.

Understanding the Manufacturing Processes

Hot rolled steel undergoes processing at temperatures above its recrystallization point, allowing easier shaping and forming by passing the metal through rollers. Cold rolled steel is produced by further processing hot rolled steel at room temperature, enhancing surface finish, dimensional accuracy, and mechanical properties through cold working techniques. Understanding these manufacturing processes is crucial for selecting suitable steel types for applications requiring specific strength, ductility, and surface quality.

Key Differences in Physical Properties

Hot rolled steel features a rough surface texture and looser tolerances due to cooling at room temperature after rolling, resulting in lower strength but higher ductility. Cold rolled steel undergoes further processing through cold reduction, producing a smoother finish, improved surface quality, and increased tensile strength with tighter dimensional tolerances. The differences in grain structure and residual stresses significantly impact hardness and formability, with cold rolled steel being preferable for applications requiring precise machining and aesthetic appeal.

Surface Finish and Appearance Comparison

Hot rolled steel features a rough, scaled surface due to the high-temperature rolling process, resulting in a matte, less refined appearance ideal for structural applications. Cold rolled steel undergoes further processing at room temperature, producing a smoother, shinier surface with tighter tolerances and enhanced aesthetic appeal suitable for precision engineering and decorative uses. The superior surface finish of cold rolled steel reduces the need for additional machining and paint adhesion issues compared to hot rolled steel.

Strength and Durability: Which is Superior?

Hot rolled steel exhibits greater durability due to its thicker, rougher surface and ability to withstand heavy loads, making it ideal for structural applications. Cold rolled steel offers superior strength and a smoother, more precise finish, enhancing performance in automotive and appliance manufacturing. Comparing both, hot rolled steel excels in toughness and impact resistance, while cold rolled steel delivers enhanced tensile strength and dimensional accuracy.

Common Applications of Hot Rolled Steel

Hot rolled steel is widely used in construction for structural components such as I-beams, rails, and metal framing due to its durability and cost-effectiveness. It is also common in manufacturing heavy machinery parts and automotive frames where strength and toughness are crucial. Additionally, hot rolled steel is favored for large-scale infrastructure projects like bridges and pipelines because of its excellent weldability and formability.

Common Uses for Cold Rolled Steel

Cold rolled steel is commonly used in automotive panels, household appliances, and furniture due to its smooth surface finish and precise dimensions. Its enhanced strength and superior surface quality make it ideal for manufacturing components that require tight tolerances and aesthetic appeal. Industries such as construction, electronics, and metal furniture extensively utilize cold rolled steel for durable and visually refined products.

Cost Considerations: Hot Rolled vs Cold Rolled

Hot rolled steel typically incurs lower production costs due to its simpler manufacturing process and reduced energy requirements, making it more affordable for large-scale structural applications. Cold rolled steel involves higher expenses from additional processing stages such as annealing and temper rolling, resulting in superior surface finish and tighter tolerances but at a premium price. Choosing between hot rolled and cold rolled steel depends on balancing budget constraints with the need for precision and aesthetic quality.

Choosing the Right Steel for Your Project

Hot rolled steel offers superior strength and durability, making it ideal for construction and heavy-duty applications, while cold rolled steel provides a smoother finish and tighter tolerances suited for precision projects like automotive parts and appliances. Evaluating project requirements such as surface finish, dimensional accuracy, and mechanical properties is crucial when selecting between hot rolled and cold rolled steel. Cost efficiency and final application environment also influence the decision, with hot rolled steel generally being more affordable and cold rolled steel preferred for detailed, aesthetic, or structural precision.

Conclusion: Summary of Key Takeaways

Hot rolled steel offers superior ductility and is typically used in construction and industrial applications where strength and flexibility are essential, while cold rolled steel provides a smoother surface finish and higher dimensional accuracy suited for precision components and automotive parts. Choosing between hot rolled and cold rolled steel depends on specific project requirements such as strength, surface quality, and tolerances. Manufacturers and engineers prioritize hot rolled steel for structural applications and cold rolled steel for detailed fabrication and aesthetic purposes.

Hot Rolled Steel vs Cold Rolled Steel Infographic

materialdif.com

materialdif.com