Ferrous metals contain iron, making them magnetic and highly susceptible to rust, which limits their use in moisture-prone environments. Non-ferrous metals, such as aluminum and copper, resist corrosion and offer superior conductivity, making them ideal for electrical and outdoor applications. The choice between ferrous and non-ferrous metals depends on factors like strength requirements, weight, and environmental exposure.

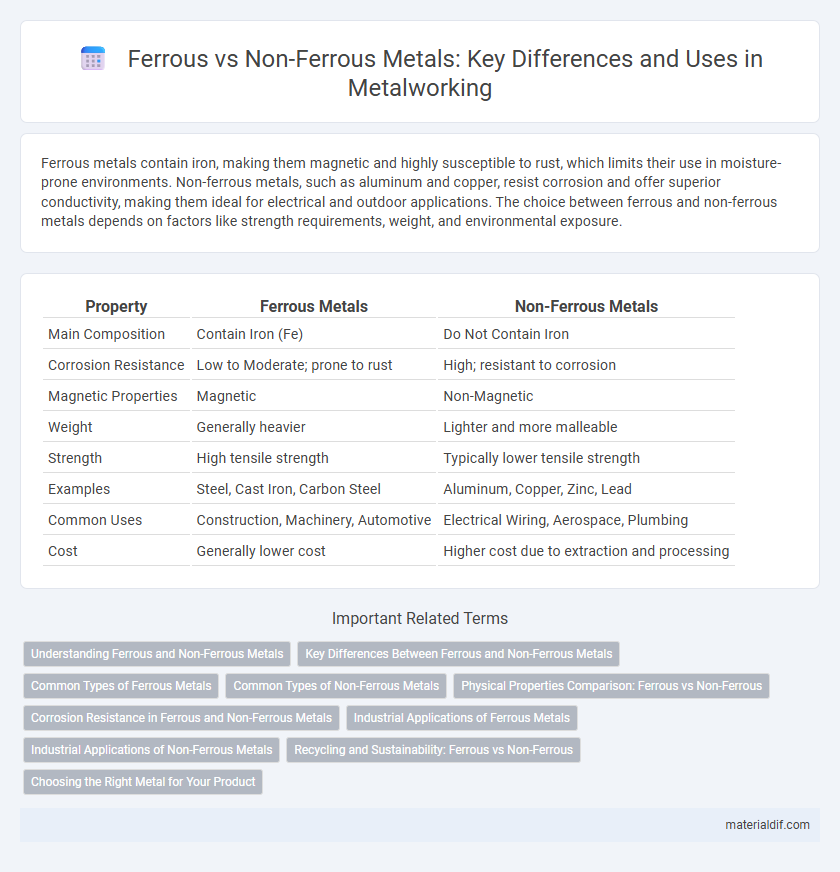

Table of Comparison

| Property | Ferrous Metals | Non-Ferrous Metals |

|---|---|---|

| Main Composition | Contain Iron (Fe) | Do Not Contain Iron |

| Corrosion Resistance | Low to Moderate; prone to rust | High; resistant to corrosion |

| Magnetic Properties | Magnetic | Non-Magnetic |

| Weight | Generally heavier | Lighter and more malleable |

| Strength | High tensile strength | Typically lower tensile strength |

| Examples | Steel, Cast Iron, Carbon Steel | Aluminum, Copper, Zinc, Lead |

| Common Uses | Construction, Machinery, Automotive | Electrical Wiring, Aerospace, Plumbing |

| Cost | Generally lower cost | Higher cost due to extraction and processing |

Understanding Ferrous and Non-Ferrous Metals

Ferrous metals contain iron, making them magnetic and highly durable, which is essential for construction and automotive industries. Non-ferrous metals lack iron, offering superior resistance to corrosion and better conductivity, important for electrical wiring and aerospace applications. Understanding these distinctions helps optimize material selection for specific industrial requirements and product longevity.

Key Differences Between Ferrous and Non-Ferrous Metals

Ferrous metals primarily contain iron and are magnetic, making them strong and ideal for construction and automotive industries; they are prone to rust without proper coating. Non-ferrous metals lack iron, exhibit higher resistance to corrosion and conductivity, and include metals like aluminum, copper, and zinc, widely used in electrical and aerospace applications. Weight differences also play a role, with non-ferrous metals generally being lighter, enhancing their suitability for lightweight structural components.

Common Types of Ferrous Metals

Common types of ferrous metals include carbon steel, cast iron, and stainless steel, each characterized by varying carbon content and alloy compositions. Carbon steel is known for its strength and versatility, making it widely used in construction and manufacturing. Cast iron offers excellent wear resistance and compressive strength, while stainless steel provides corrosion resistance through its chromium content, making it ideal for medical instruments and kitchenware.

Common Types of Non-Ferrous Metals

Common types of non-ferrous metals include aluminum, copper, lead, nickel, tin, and zinc, each prized for distinct properties like corrosion resistance, conductivity, and malleability. Aluminum is lightweight and highly resistant to oxidation, making it ideal for aerospace and automotive applications. Copper excels in electrical conductivity, essential for wiring and electronic components, while zinc and tin serve crucial roles in galvanization and soldering respectively.

Physical Properties Comparison: Ferrous vs Non-Ferrous

Ferrous metals contain iron, making them magnetic, dense, and susceptible to corrosion, whereas non-ferrous metals lack iron, resulting in non-magnetic properties, superior corrosion resistance, and generally lower density. Ferrous metals like steel and cast iron exhibit high tensile strength and hardness, while non-ferrous metals such as aluminum, copper, and zinc offer excellent malleability and thermal conductivity. The physical differences influence their applications, with ferrous metals preferred for structural uses and non-ferrous metals favored in electrical, aerospace, and corrosion-resistant components.

Corrosion Resistance in Ferrous and Non-Ferrous Metals

Non-ferrous metals exhibit superior corrosion resistance compared to ferrous metals due to their lower iron content, which reduces the tendency to oxidize and form rust. Aluminum, copper, and stainless steel are notable non-ferrous metals with enhanced corrosion resistance owing to their oxide film formation that protects against environmental damage. In contrast, typical ferrous metals like carbon steel are more prone to rusting, requiring protective coatings to improve their durability in corrosive environments.

Industrial Applications of Ferrous Metals

Ferrous metals, primarily composed of iron and its alloys, dominate industrial applications due to their high tensile strength, durability, and magnetic properties. These metals are extensively used in construction, automotive manufacturing, heavy machinery, and infrastructure development where corrosion resistance and load-bearing capacity are critical. Steel, a key ferrous alloy, is particularly valued for its versatility in producing structural frameworks, tools, and industrial equipment.

Industrial Applications of Non-Ferrous Metals

Non-ferrous metals such as aluminum, copper, and titanium play crucial roles in aerospace, automotive, and electrical industries due to their superior corrosion resistance, lightweight properties, and excellent conductivity. Applications include aircraft structural components, electrical wiring, and heat exchangers, where strength-to-weight ratio and resistance to oxidation are critical. The high cost and recyclability of non-ferrous metals further enhance their industrial value in sustainable manufacturing.

Recycling and Sustainability: Ferrous vs Non-Ferrous

Ferrous metals, primarily composed of iron and steel, are highly recyclable and dominate recycling industries due to their magnetic properties and economic efficiency in reprocessing. Non-ferrous metals like aluminum, copper, and zinc offer superior corrosion resistance and conductivity, making them vital in sustainable technologies and energy-efficient applications while also being fully recyclable without quality loss. Recycling ferrous metals reduces carbon emissions significantly, but non-ferrous metal recycling is critical for conserving scarce resources and minimizing environmental impact in high-tech and renewable energy sectors.

Choosing the Right Metal for Your Product

Ferrous metals, primarily composed of iron and carbon, offer high strength, durability, and magnetic properties ideal for construction and automotive applications. Non-ferrous metals such as aluminum, copper, and brass provide superior corrosion resistance, electrical conductivity, and lightweight characteristics essential for aerospace, electrical, and decorative products. Selecting the right metal depends on key factors including mechanical properties, environmental exposure, weight requirements, and cost-effectiveness tailored to the product's specific performance needs.

Ferrous metals vs Non-ferrous metals Infographic

materialdif.com

materialdif.com