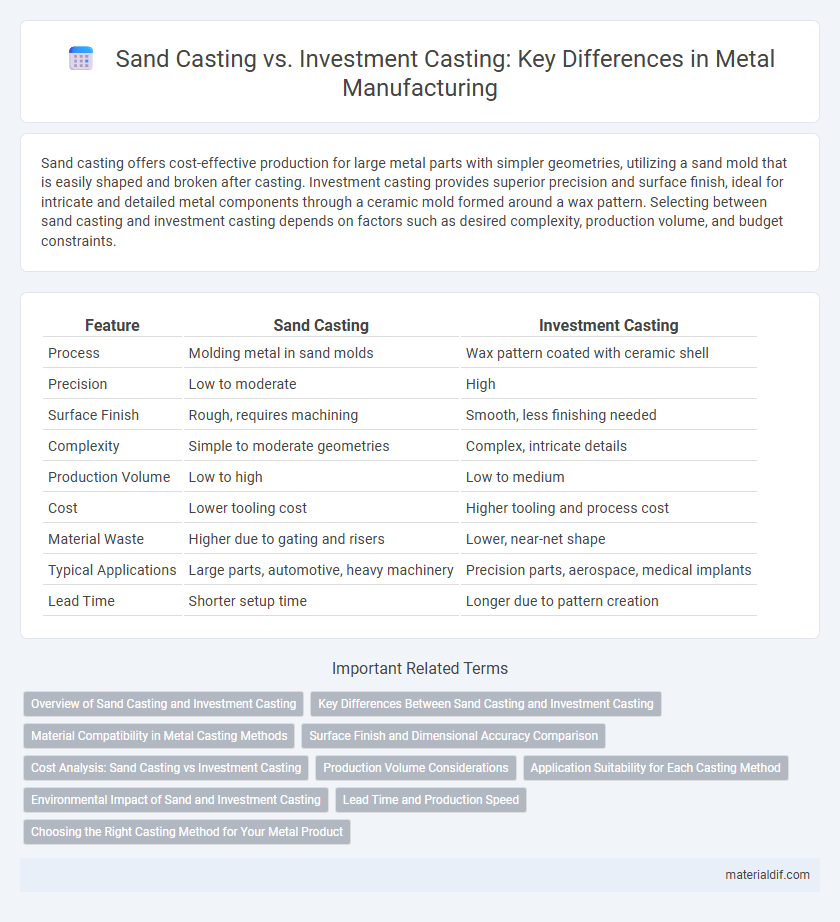

Sand casting offers cost-effective production for large metal parts with simpler geometries, utilizing a sand mold that is easily shaped and broken after casting. Investment casting provides superior precision and surface finish, ideal for intricate and detailed metal components through a ceramic mold formed around a wax pattern. Selecting between sand casting and investment casting depends on factors such as desired complexity, production volume, and budget constraints.

Table of Comparison

| Feature | Sand Casting | Investment Casting |

|---|---|---|

| Process | Molding metal in sand molds | Wax pattern coated with ceramic shell |

| Precision | Low to moderate | High |

| Surface Finish | Rough, requires machining | Smooth, less finishing needed |

| Complexity | Simple to moderate geometries | Complex, intricate details |

| Production Volume | Low to high | Low to medium |

| Cost | Lower tooling cost | Higher tooling and process cost |

| Material Waste | Higher due to gating and risers | Lower, near-net shape |

| Typical Applications | Large parts, automotive, heavy machinery | Precision parts, aerospace, medical implants |

| Lead Time | Shorter setup time | Longer due to pattern creation |

Overview of Sand Casting and Investment Casting

Sand casting uses a mold made from compacted sand, ideal for producing large metal parts with complex geometries and rough surface finishes. Investment casting employs a wax pattern coated with ceramic material, enabling precise, detailed components with smooth surfaces and high dimensional accuracy. Both processes are versatile but differ in cost, production speed, and the level of detail achievable in the final metal product.

Key Differences Between Sand Casting and Investment Casting

Sand casting involves creating a mold from compacted sand, allowing for affordable production of large metal parts with moderate dimensional accuracy and surface finish. Investment casting, also known as lost-wax casting, uses a wax pattern coated with ceramic material to produce highly detailed, complex parts with superior surface quality and tight tolerances. Key differences between these processes include cost, precision, surface finish, and suitability for intricate designs, with sand casting preferred for large, less detailed components and investment casting ideal for small, complex metal parts.

Material Compatibility in Metal Casting Methods

Sand casting excels in compatibility with ferrous metals like cast iron and steel, accommodating large components and complex shapes at lower costs. Investment casting offers superior precision and is ideal for non-ferrous metals such as stainless steel, aluminum, and titanium, enabling intricate details and tighter tolerances. Material selection depends on the metal's melting point, desired surface finish, and mechanical properties specific to the casting method.

Surface Finish and Dimensional Accuracy Comparison

Sand casting produces parts with a rough surface finish and lower dimensional accuracy due to the coarse sand mold material, resulting in more post-processing. Investment casting offers superior surface finish with smooth and detailed surfaces, achieved through precision wax patterns and ceramic molds. Dimensional accuracy in investment casting is significantly higher, enabling the creation of complex geometries with tight tolerances, ideal for critical metal components.

Cost Analysis: Sand Casting vs Investment Casting

Sand casting typically incurs lower initial tooling costs compared to investment casting, making it more cost-effective for small production runs and larger parts. Investment casting involves higher upfront expenses due to intricate mold creation but offers superior precision and reduced post-processing, which can lower overall costs for complex, high-volume components. Choosing between sand casting and investment casting depends on factors like production volume, part complexity, and required surface finish quality.

Production Volume Considerations

Sand casting suits high-volume production due to its cost-effective mold creation and ability to handle large, complex parts with relatively quick turnaround times. Investment casting excels in low to medium production volumes by delivering superior precision and intricate detail, minimizing machining requirements and material waste. Selection between these methods hinges on balancing production volume with desired surface finish quality and dimensional accuracy.

Application Suitability for Each Casting Method

Sand casting is ideal for producing large, complex metal parts such as engine blocks, pump housings, and heavy machinery components due to its cost-effectiveness and ability to handle a wide range of metals. Investment casting excels in creating intricate, precise parts with fine surface finishes, commonly used in aerospace components, medical devices, and turbine blades where tolerance and detail are critical. Each method's application suitability depends on factors like part complexity, production volume, and required material properties.

Environmental Impact of Sand and Investment Casting

Sand casting generates significant waste due to the disposal of silica-based sand and consumes large volumes of water for cooling, leading to environmental challenges such as soil contamination and resource depletion. Investment casting, while requiring higher energy inputs for wax melting and ceramic shell firing, produces less solid waste and allows for better material efficiency, reducing scrap metal and minimizing ecological footprint. The choice between these methods impacts emissions, resource usage, and waste management, with investment casting generally offering a more sustainable option despite higher initial energy consumption.

Lead Time and Production Speed

Sand casting offers shorter lead times and faster production speeds due to its simple mold-making process and quick cycle times, making it ideal for large, low-volume parts. Investment casting involves longer lead times because of its detailed wax pattern creation and ceramic shell building, but it delivers higher precision and smoother surface finishes. Production speed in investment casting is slower but better suited for complex geometries requiring tight tolerances.

Choosing the Right Casting Method for Your Metal Product

Sand casting excels in producing large, complex metal parts with excellent dimensional accuracy and cost-effectiveness for small to medium production runs. Investment casting offers superior surface finish, intricate detail, and tighter tolerances, making it ideal for high-precision components in aerospace and medical industries. Selecting the right casting method depends on factors such as part size, complexity, production volume, and required mechanical properties to ensure optimal performance and cost efficiency.

Sand Casting vs Investment Casting Infographic

materialdif.com

materialdif.com