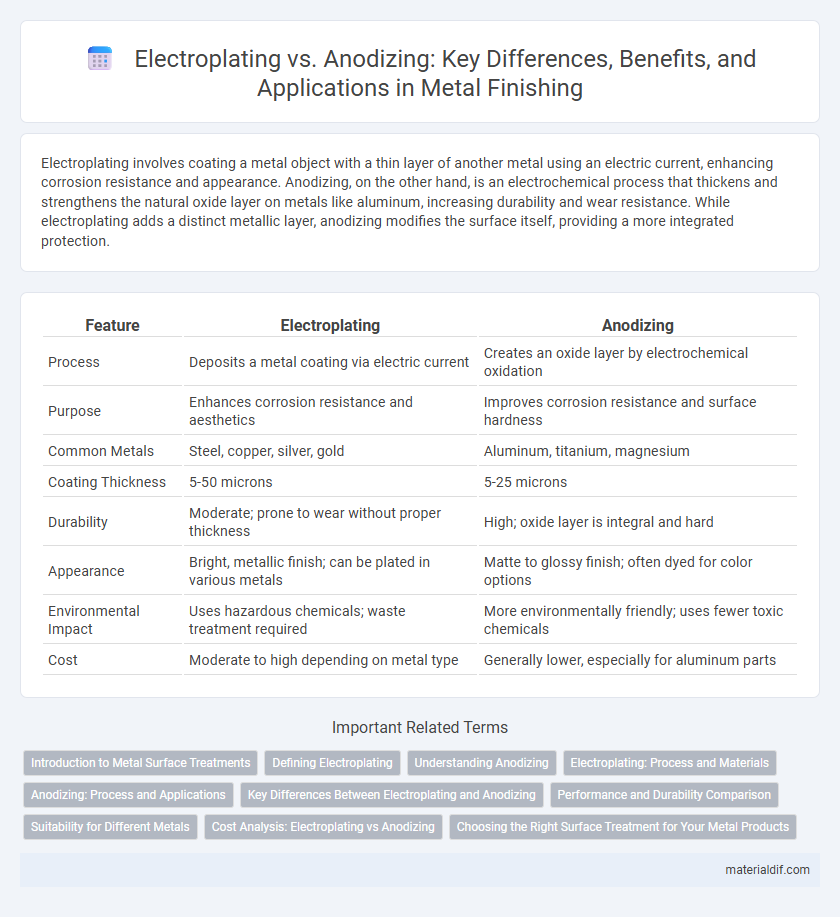

Electroplating involves coating a metal object with a thin layer of another metal using an electric current, enhancing corrosion resistance and appearance. Anodizing, on the other hand, is an electrochemical process that thickens and strengthens the natural oxide layer on metals like aluminum, increasing durability and wear resistance. While electroplating adds a distinct metallic layer, anodizing modifies the surface itself, providing a more integrated protection.

Table of Comparison

| Feature | Electroplating | Anodizing |

|---|---|---|

| Process | Deposits a metal coating via electric current | Creates an oxide layer by electrochemical oxidation |

| Purpose | Enhances corrosion resistance and aesthetics | Improves corrosion resistance and surface hardness |

| Common Metals | Steel, copper, silver, gold | Aluminum, titanium, magnesium |

| Coating Thickness | 5-50 microns | 5-25 microns |

| Durability | Moderate; prone to wear without proper thickness | High; oxide layer is integral and hard |

| Appearance | Bright, metallic finish; can be plated in various metals | Matte to glossy finish; often dyed for color options |

| Environmental Impact | Uses hazardous chemicals; waste treatment required | More environmentally friendly; uses fewer toxic chemicals |

| Cost | Moderate to high depending on metal type | Generally lower, especially for aluminum parts |

Introduction to Metal Surface Treatments

Electroplating and anodizing are essential metal surface treatments that enhance corrosion resistance and aesthetic appeal. Electroplating deposits a thin layer of metal, such as chromium or nickel, onto the substrate to improve conductivity and prevent oxidation. Anodizing, primarily used for aluminum, thickens the natural oxide layer, increasing durability and providing a porous surface for dyeing or sealing.

Defining Electroplating

Electroplating is a metal finishing process that uses an electric current to deposit a thin layer of metal onto the surface of a substrate, improving corrosion resistance, appearance, and wear properties. This technique typically involves immersing the base metal into an electrolyte solution containing ions of the plating metal, such as nickel, chromium, or gold. Unlike anodizing, which oxidizes the metal surface to create a protective film, electroplating adds a physical metal coating to enhance surface characteristics.

Understanding Anodizing

Anodizing is an electrochemical process that enhances the natural oxide layer on metals like aluminum, increasing corrosion resistance and surface hardness. Unlike electroplating, which deposits a layer of metal onto the surface, anodizing converts the metal surface into a durable, porous oxide layer that can also absorb dyes for improved aesthetics. This method is widely used in aerospace, automotive, and architectural applications for long-lasting protection and vibrant finishes.

Electroplating: Process and Materials

Electroplating involves depositing a thin layer of metal onto a conductive surface using an electrolytic cell, where the object acts as the cathode and metal ions in solution are reduced onto its surface. Common materials used in electroplating include metals such as nickel, chromium, copper, and gold, selected based on their corrosion resistance, aesthetic appeal, and electrical conductivity. This process enhances surface properties like hardness, wear resistance, and corrosion protection for a wide range of metal components in industries including automotive, electronics, and jewelry.

Anodizing: Process and Applications

Anodizing is an electrochemical process that enhances the natural oxide layer on metal surfaces, primarily aluminum, by immersing the metal in an acid electrolyte bath and applying an electric current. This process improves corrosion resistance, surface hardness, and allows for vibrant dye absorption, making it ideal for aerospace components, architectural panels, and consumer electronics. Anodized aluminum offers superior durability and aesthetic appeal compared to electroplated metals, which rely on depositing external metal layers.

Key Differences Between Electroplating and Anodizing

Electroplating involves depositing a thin layer of metal, such as chromium or nickel, onto a substrate to enhance corrosion resistance and aesthetic appeal, whereas anodizing creates a durable oxide layer typically on aluminum surfaces for improved wear resistance and color stability. Electroplating uses an electric current to reduce metal cations onto the base material, while anodizing is an electrolytic passivation process that thickens the natural oxide layer. The key differences also include the types of metals treated, with electroplating applicable to a wide range of metals and anodizing primarily used for aluminum and titanium.

Performance and Durability Comparison

Electroplating enhances metal surfaces by depositing a layer of metal, improving corrosion resistance and aesthetic appeal but may wear off over time under harsh conditions. Anodizing creates a thick oxide layer on aluminum, offering superior resistance to corrosion, wear, and UV exposure, resulting in longer-lasting protection. For performance and durability, anodizing generally provides a more robust and maintenance-free finish compared to electroplating, especially in outdoor and high-wear applications.

Suitability for Different Metals

Electroplating is highly suitable for metals like steel, copper, and aluminum due to its ability to deposit a thin layer of conductive metal such as nickel, chromium, or gold, enhancing corrosion resistance and aesthetic appeal. Anodizing primarily applies to aluminum alloys, titanium, and magnesium, where it thickens the natural oxide layer to improve wear resistance and surface hardness without adding material. The choice between electroplating and anodizing depends on the metal substrate and desired properties, with electroplating favored for versatile metal finishes and anodizing preferred for lightweight, corrosion-resistant aluminum components.

Cost Analysis: Electroplating vs Anodizing

Electroplating generally incurs higher initial costs due to expensive metal salts and complex waste disposal requirements, but it offers a thinner, more uniform coating suitable for corrosion resistance and decorative finishes. Anodizing presents a more cost-effective solution with lower environmental impact and maintenance expenses, especially for aluminum substrates, by creating a durable oxide layer through an electrochemical process. Evaluating long-term expenses, anodizing often proves more economical for large-scale applications, while electroplating prioritizes precise metal deposition where material-specific properties are critical.

Choosing the Right Surface Treatment for Your Metal Products

Electroplating provides a thin metal coating that enhances corrosion resistance and improves aesthetic appeal, making it ideal for decorative and conductive applications. Anodizing thickens the natural oxide layer on metals like aluminum, offering superior durability and resistance to wear and environmental damage. Selecting the appropriate surface treatment depends on factors such as desired finish, corrosion protection level, and the specific metal substrate involved.

Electroplating vs Anodizing Infographic

materialdif.com

materialdif.com