Sheet metal stamping involves shaping thin metal sheets into precise forms through a press and die, ideal for high-volume production with intricate designs. Metal forging uses compressive forces to shape heated metal, resulting in parts with superior strength and durability, suitable for applications requiring high structural integrity. Choosing between these processes depends on the desired mechanical properties, production volume, and complexity of the metal component.

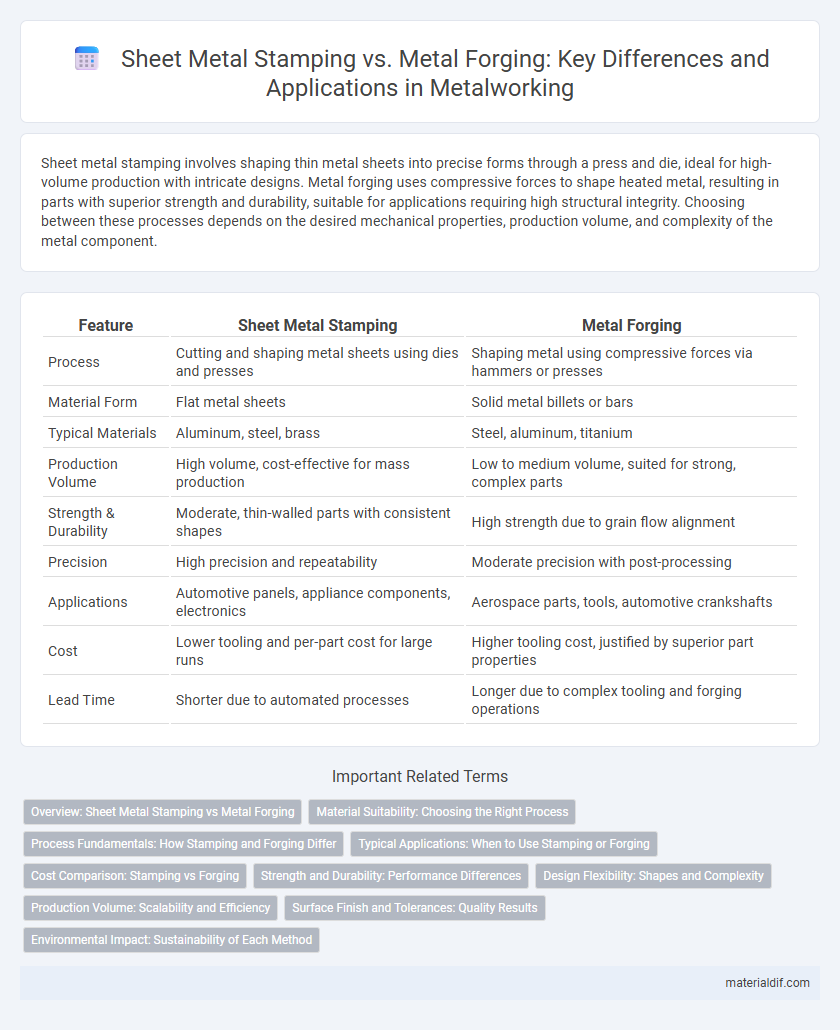

Table of Comparison

| Feature | Sheet Metal Stamping | Metal Forging |

|---|---|---|

| Process | Cutting and shaping metal sheets using dies and presses | Shaping metal using compressive forces via hammers or presses |

| Material Form | Flat metal sheets | Solid metal billets or bars |

| Typical Materials | Aluminum, steel, brass | Steel, aluminum, titanium |

| Production Volume | High volume, cost-effective for mass production | Low to medium volume, suited for strong, complex parts |

| Strength & Durability | Moderate, thin-walled parts with consistent shapes | High strength due to grain flow alignment |

| Precision | High precision and repeatability | Moderate precision with post-processing |

| Applications | Automotive panels, appliance components, electronics | Aerospace parts, tools, automotive crankshafts |

| Cost | Lower tooling and per-part cost for large runs | Higher tooling cost, justified by superior part properties |

| Lead Time | Shorter due to automated processes | Longer due to complex tooling and forging operations |

Overview: Sheet Metal Stamping vs Metal Forging

Sheet metal stamping involves shaping flat metal sheets using dies and presses to create precise, complex parts efficiently, often used for automotive and appliance industries. Metal forging is a high-temperature process that deforms metal billets through compressive forces, producing parts with superior strength and fatigue resistance commonly applied in aerospace and heavy machinery. Both processes serve distinct manufacturing needs, with stamping prioritizing high-volume production and intricate designs, while forging delivers enhanced mechanical properties and durability.

Material Suitability: Choosing the Right Process

Sheet metal stamping excels with thin, ductile metals like aluminum and mild steel, offering precision for complex shapes in high-volume production. Metal forging suits tougher materials such as carbon steel, stainless steel, and titanium, enhancing strength and durability through controlled deformation. Selecting the right process depends on the material's thickness, mechanical properties, and the desired part strength.

Process Fundamentals: How Stamping and Forging Differ

Sheet metal stamping involves shaping thin metal sheets into specific forms using dies and high-pressure presses, allowing for precise, repeatable, and high-speed production of complex parts. Metal forging, by contrast, uses compressive forces to shape heated metal billets or ingots, enhancing mechanical properties through grain refinement and producing stronger, more durable components. The primary difference lies in stamping's material deformation at room temperature for detailed shapes versus forging's plastic deformation at elevated temperatures to optimize strength and structural integrity.

Typical Applications: When to Use Stamping or Forging

Sheet metal stamping is ideal for high-volume production of precise, intricate components like automotive panels, appliances, and electronic enclosures where consistent repetition and tight tolerances are critical. Metal forging excels in creating strong, durable parts such as crankshafts, gears, and aircraft landing gear that require superior mechanical properties and resistance to fatigue. Selecting stamping or forging depends on the balance between production volume, geometric complexity, and the mechanical strength requirements of the final product.

Cost Comparison: Stamping vs Forging

Sheet metal stamping offers lower initial tooling costs and faster production cycles, making it cost-effective for high-volume manufacturing of thin metal parts. Metal forging involves higher upfront equipment and tooling expenses but produces stronger, more durable components ideal for high-stress applications. Cost efficiency depends on production volume, part complexity, and material properties, with stamping favored for mass production and forging preferred for quality and strength.

Strength and Durability: Performance Differences

Sheet metal stamping produces components with precise dimensions and smooth surfaces, ideal for lightweight applications but generally offers lower strength compared to forged parts. Metal forging involves deforming metal under high pressure, resulting in a denser grain structure that significantly enhances tensile strength and durability. Forged metal components excel in high-stress environments, making them the preferred choice for critical structural applications requiring superior mechanical performance.

Design Flexibility: Shapes and Complexity

Sheet metal stamping offers exceptional design flexibility, enabling the creation of intricate shapes and highly detailed patterns with precise tolerances. Metal forging, while producing stronger and more durable parts, is generally limited to simpler geometries due to the deformation process. Complex, thin-walled, or detailed components are better suited for stamping, whereas forging excels in producing robust, load-bearing structures with less design complexity.

Production Volume: Scalability and Efficiency

Sheet metal stamping offers high scalability and efficiency for large production volumes due to its automated processes and rapid cycle times, making it ideal for mass manufacturing. Metal forging, while providing superior strength and durability in parts, is less efficient and slower for high-volume production because of its labor-intensive and time-consuming operations. Choosing between the two methods depends on balancing the need for production speed with the mechanical properties required in the final metal component.

Surface Finish and Tolerances: Quality Results

Sheet metal stamping offers high precision with tight tolerances, typically achieving surface finishes ranging from 32 to 125 microinches Ra, ideal for detailed and consistent parts. Metal forging produces superior mechanical properties with slightly looser tolerances but often requires additional finishing processes to reach comparable surface quality. Both methods yield quality results, with stamping excelling in smooth surface finishes and precise dimensions, while forging provides enhanced strength and durability.

Environmental Impact: Sustainability of Each Method

Sheet metal stamping generates less waste and consumes less energy compared to metal forging, making it a more environmentally sustainable option for mass production. Metal forging demands higher temperatures and energy inputs, resulting in increased carbon emissions and resource usage. Recycling stamped sheet metal is also more efficient, reducing the overall environmental footprint of manufacturing processes.

Sheet Metal Stamping vs Metal Forging Infographic

materialdif.com

materialdif.com