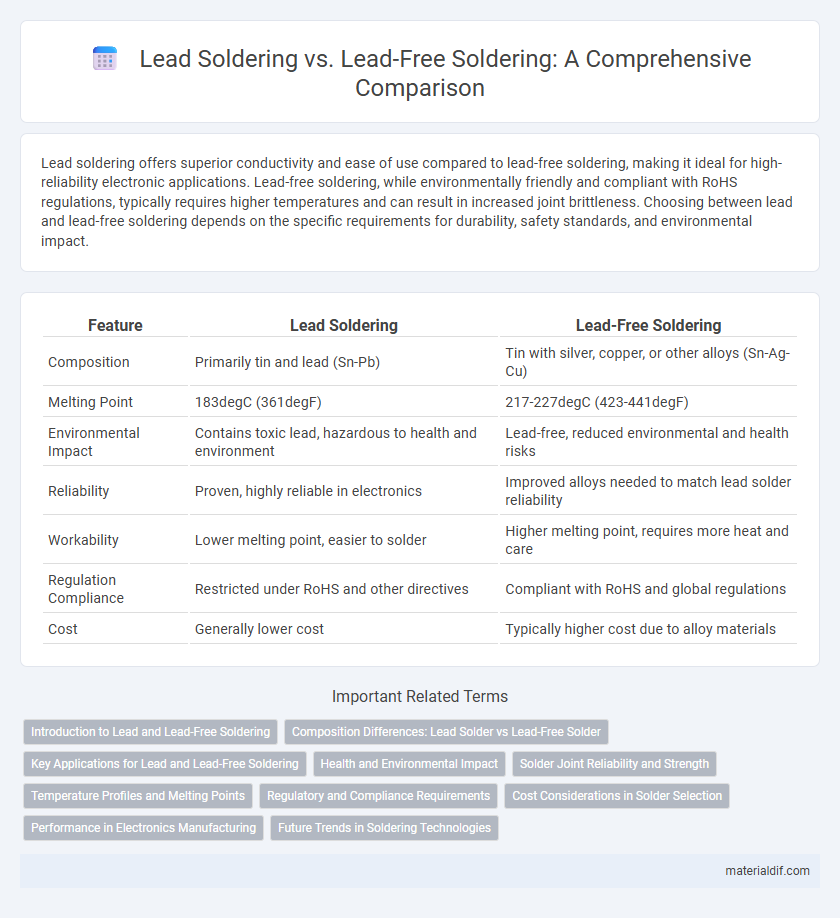

Lead soldering offers superior conductivity and ease of use compared to lead-free soldering, making it ideal for high-reliability electronic applications. Lead-free soldering, while environmentally friendly and compliant with RoHS regulations, typically requires higher temperatures and can result in increased joint brittleness. Choosing between lead and lead-free soldering depends on the specific requirements for durability, safety standards, and environmental impact.

Table of Comparison

| Feature | Lead Soldering | Lead-Free Soldering |

|---|---|---|

| Composition | Primarily tin and lead (Sn-Pb) | Tin with silver, copper, or other alloys (Sn-Ag-Cu) |

| Melting Point | 183degC (361degF) | 217-227degC (423-441degF) |

| Environmental Impact | Contains toxic lead, hazardous to health and environment | Lead-free, reduced environmental and health risks |

| Reliability | Proven, highly reliable in electronics | Improved alloys needed to match lead solder reliability |

| Workability | Lower melting point, easier to solder | Higher melting point, requires more heat and care |

| Regulation Compliance | Restricted under RoHS and other directives | Compliant with RoHS and global regulations |

| Cost | Generally lower cost | Typically higher cost due to alloy materials |

Introduction to Lead and Lead-Free Soldering

Lead soldering utilizes alloys primarily composed of tin and lead, offering low melting points and excellent electrical conductivity, which has made it a standard in electronics assembly for decades. Lead-free soldering, commonly formulated from tin combined with silver, copper, or other metals, addresses environmental and health concerns by eliminating toxic lead content while maintaining solder joint reliability. The transition from lead to lead-free soldering reflects regulatory standards like RoHS, emphasizing safer materials without compromising performance in electronic manufacturing.

Composition Differences: Lead Solder vs Lead-Free Solder

Lead solder typically contains a high percentage of tin combined with around 60% lead, providing low melting points and excellent wetting properties for reliable electrical connections. In contrast, lead-free solder alloys commonly use tin as the base metal mixed with silver, copper, or bismuth, which increases melting temperatures and can affect joint mechanical strength. These compositional differences impact soldering techniques, thermal profiles, and environmental compliance, with lead-free solders favored for RoHS certification and reduced toxicity.

Key Applications for Lead and Lead-Free Soldering

Lead soldering remains widely used in automotive and aerospace industries due to its superior mechanical strength and reliable thermal fatigue resistance. Lead-free soldering is preferred in consumer electronics and medical devices to meet stringent environmental regulations like RoHS, promoting eco-friendly manufacturing. Both soldering types play crucial roles: lead for high-stress, long-life applications and lead-free for reduced toxicity and compliance requirements.

Health and Environmental Impact

Lead soldering releases toxic lead particles posing significant health risks, including neurological damage and developmental issues, especially in occupational settings. Lead-free soldering, typically using tin, silver, and copper alloys, minimizes these health hazards and reduces environmental contamination. However, lead-free solders may require higher temperatures and can impact electronic reliability, balancing health benefits with technical performance.

Solder Joint Reliability and Strength

Lead soldering typically offers superior solder joint reliability and mechanical strength due to its lower melting point and better wetting properties, resulting in more uniform and defect-free joints. Lead-free soldering often faces challenges such as increased brittleness and higher incidence of voids or cracks, which can compromise long-term joint durability under thermal cycling. Advances in lead-free alloys, such as SAC305 (Tin-Silver-Copper), have improved solder joint reliability, but leaded solders generally still outperform in critical applications requiring maximum joint strength.

Temperature Profiles and Melting Points

Lead soldering commonly uses alloys with melting points around 183degC, enabling lower temperature profiles that reduce thermal stress on components. Lead-free soldering typically requires higher temperatures, often exceeding 217degC due to alloys like SAC305, which affects PCB and component durability. Managing these temperature profiles is essential to prevent damage and ensure reliable solder joints in electronic assembly processes.

Regulatory and Compliance Requirements

Lead soldering faces stringent regulatory restrictions due to its toxic lead content, with norms like RoHS (Restriction of Hazardous Substances) and REACH limiting its use in electronics manufacturing. Lead-free soldering complies with these regulations by utilizing alternatives such as tin-silver-copper alloys, significantly reducing hazardous substance emissions. Manufacturers must ensure compliance through rigorous testing and certification processes to meet global environmental and safety standards.

Cost Considerations in Solder Selection

Lead soldering typically offers lower material costs due to the widespread availability and lower price of lead-based alloys compared to lead-free alternatives. Lead-free soldering incurs higher initial expenses owing to the use of more expensive metals like silver, copper, and tin, as well as increased energy consumption during the higher melting temperature process. Long-term cost factors include potential savings in waste management and regulatory compliance with lead-free options, offsetting the upfront cost differences in some manufacturing environments.

Performance in Electronics Manufacturing

Lead soldering provides superior electrical conductivity and lower melting points, resulting in efficient heat transfer and reliable joints in electronics manufacturing. Lead-free soldering emphasizes environmental compliance and health safety but often requires higher temperatures, which can stress components and potentially affect joint durability. Performance trade-offs between lead and lead-free soldering influence production yield, long-term reliability, and overall product lifespan in electronic assemblies.

Future Trends in Soldering Technologies

Future trends in soldering technologies emphasize the shift from traditional lead soldering to lead-free alternatives due to environmental regulations such as RoHS compliance. Advances in lead-free solder materials, including tin-silver-copper (SAC) alloys, improve joint reliability and thermal fatigue resistance in electronics manufacturing. Emerging techniques like laser soldering and flux-free soldering aim to enhance precision and reduce the environmental impact of soldering processes.

Lead Soldering vs Lead-Free Soldering Infographic

materialdif.com

materialdif.com