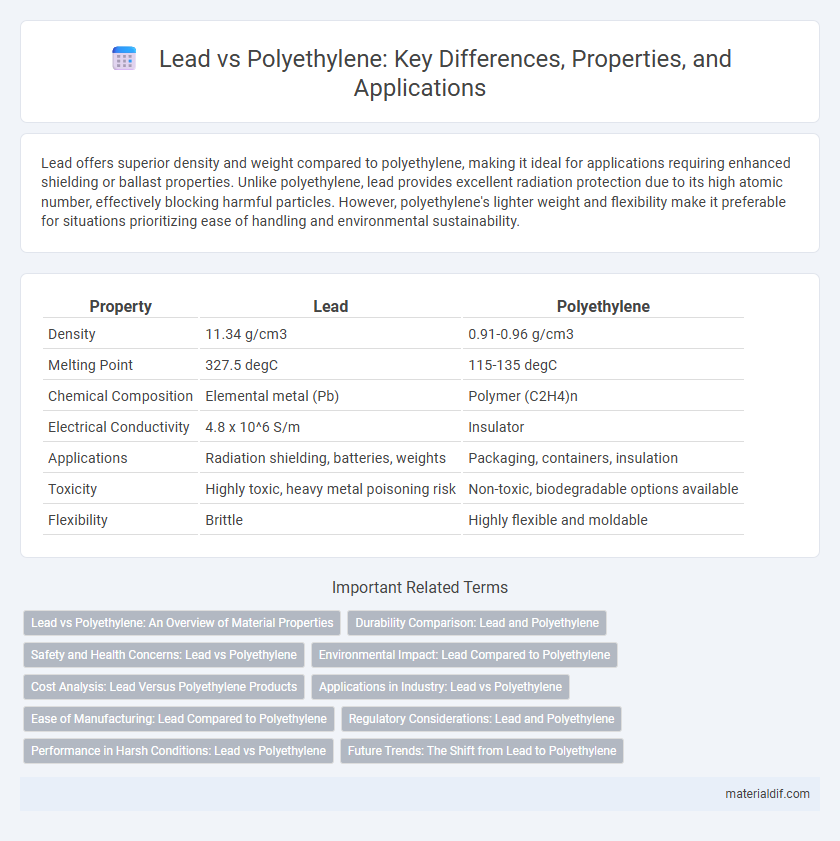

Lead offers superior density and weight compared to polyethylene, making it ideal for applications requiring enhanced shielding or ballast properties. Unlike polyethylene, lead provides excellent radiation protection due to its high atomic number, effectively blocking harmful particles. However, polyethylene's lighter weight and flexibility make it preferable for situations prioritizing ease of handling and environmental sustainability.

Table of Comparison

| Property | Lead | Polyethylene |

|---|---|---|

| Density | 11.34 g/cm3 | 0.91-0.96 g/cm3 |

| Melting Point | 327.5 degC | 115-135 degC |

| Chemical Composition | Elemental metal (Pb) | Polymer (C2H4)n |

| Electrical Conductivity | 4.8 x 10^6 S/m | Insulator |

| Applications | Radiation shielding, batteries, weights | Packaging, containers, insulation |

| Toxicity | Highly toxic, heavy metal poisoning risk | Non-toxic, biodegradable options available |

| Flexibility | Brittle | Highly flexible and moldable |

Lead vs Polyethylene: An Overview of Material Properties

Lead exhibits high density, excellent radiation shielding, and superior malleability, making it ideal for protective applications, whereas polyethylene is lightweight, chemically resistant, and offers high impact strength suitable for packaging and insulation. Lead's atomic number (82) contributes to its effectiveness in blocking X-rays and gamma rays, contrasting with polyethylene's molecular structure that provides flexibility and environmental resistance. Thermal conductivity differs significantly, with lead conducting heat efficiently while polyethylene acts as an insulator, influencing their respective uses in industrial and medical fields.

Durability Comparison: Lead and Polyethylene

Lead exhibits superior durability due to its high density and resistance to corrosion, making it ideal for long-term applications in harsh environments. Polyethylene, while resistant to impact and chemical degradation, tends to degrade under prolonged UV exposure and extreme temperatures, limiting its lifespan compared to lead. In terms of durability, lead outperforms polyethylene in structural stability and resistance to environmental factors.

Safety and Health Concerns: Lead vs Polyethylene

Lead exposure poses significant health risks, including neurotoxicity, kidney damage, and developmental issues, making it a major safety concern in various applications. Polyethylene, a common plastic polymer, is generally considered safe and inert, with minimal health hazards under normal use conditions. Unlike lead, polyethylene does not release harmful toxins, reducing the risk of contamination and chronic health problems in both industrial and consumer settings.

Environmental Impact: Lead Compared to Polyethylene

Lead poses significant environmental risks due to its toxicity, accumulation in soil and water, and persistence in ecosystems, leading to bioaccumulation and harm to wildlife and human health. Polyethylene, a widely used plastic, contributes to environmental pollution primarily through its non-biodegradability and potential to form microplastics, though it is less toxic than lead. Compared to polyethylene, lead's heavy metal contamination presents more severe long-term ecological and health hazards, despite polyethylene's challenges in waste management and pollution.

Cost Analysis: Lead Versus Polyethylene Products

Lead products typically present higher material and handling costs due to their weight and toxicity compared to polyethylene. Polyethylene offers cost advantages with lower raw material expenses, ease of manufacturing, and reduced transportation costs attributed to its lightweight nature. Maintenance and disposal expenses also favor polyethylene, making it a more economical option for applications requiring corrosion resistance and flexibility.

Applications in Industry: Lead vs Polyethylene

Lead excels in applications requiring high radiation shielding and corrosion resistance, such as in nuclear reactors, batteries, and cable sheathing. Polyethylene is favored in packaging, insulation, and chemical processing due to its lightweight, flexibility, and excellent chemical resistance. Industries select lead for durability under extreme conditions, while polyethylene is preferred for cost-effective, versatile, and non-toxic solutions.

Ease of Manufacturing: Lead Compared to Polyethylene

Lead offers superior ease of manufacturing due to its low melting point of 327.5degC, enabling simple casting and shaping processes compared to polyethylene's higher melting range of 115-135degC which requires more specialized extrusion or molding techniques. The malleability and ductility of lead allow for effortless fabrication into complex forms without extensive tooling adjustments, whereas polyethylene often demands precise temperature controls and pressure settings to prevent deformation. Lead's inherent machinability and lower processing energy result in reduced production times and costs relative to polyethylene.

Regulatory Considerations: Lead and Polyethylene

Lead is heavily regulated due to its toxicity, with strict limits imposed by agencies such as the EPA and OSHA to minimize exposure and environmental contamination. Polyethylene, classified as a non-toxic polymer, faces fewer regulatory constraints and is widely approved for food packaging and medical use by authorities like the FDA. Compliance with lead regulations requires ongoing monitoring and risk mitigation, whereas polyethylene's regulatory focus centers on product safety standards and environmental impact through recycling protocols.

Performance in Harsh Conditions: Lead vs Polyethylene

Lead exhibits superior resistance to extreme temperatures and corrosive environments compared to polyethylene, making it ideal for harsh industrial applications. Unlike polyethylene, lead maintains structural integrity under prolonged exposure to acids, alkalis, and intense radiation. Polyethylene tends to degrade and lose mechanical strength in such conditions, limiting its effectiveness where durability and chemical resistance are critical.

Future Trends: The Shift from Lead to Polyethylene

The shift from lead to polyethylene in industries like construction, plumbing, and packaging is driven by polyethylene's superior corrosion resistance, lightweight properties, and environmental safety. Future trends highlight increased adoption of high-density polyethylene (HDPE) applications due to regulatory restrictions on lead usage and a global push for sustainable materials. Innovations in polyethylene composites and recycling technologies further accelerate this transition, emphasizing reduced health risks and enhanced durability.

Lead vs Polyethylene Infographic

materialdif.com

materialdif.com