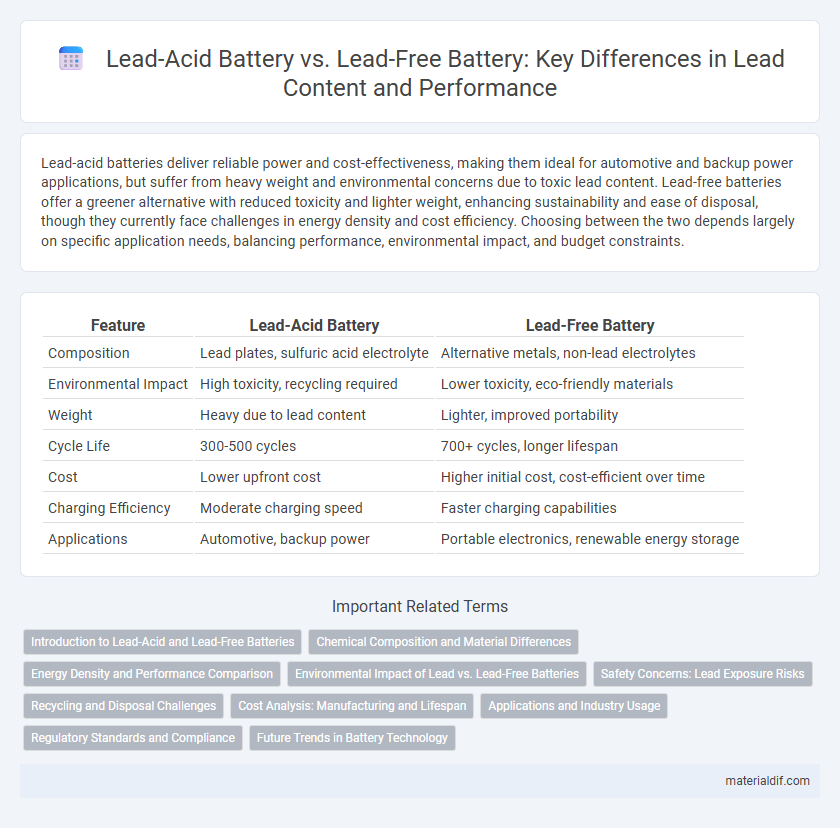

Lead-acid batteries deliver reliable power and cost-effectiveness, making them ideal for automotive and backup power applications, but suffer from heavy weight and environmental concerns due to toxic lead content. Lead-free batteries offer a greener alternative with reduced toxicity and lighter weight, enhancing sustainability and ease of disposal, though they currently face challenges in energy density and cost efficiency. Choosing between the two depends largely on specific application needs, balancing performance, environmental impact, and budget constraints.

Table of Comparison

| Feature | Lead-Acid Battery | Lead-Free Battery |

|---|---|---|

| Composition | Lead plates, sulfuric acid electrolyte | Alternative metals, non-lead electrolytes |

| Environmental Impact | High toxicity, recycling required | Lower toxicity, eco-friendly materials |

| Weight | Heavy due to lead content | Lighter, improved portability |

| Cycle Life | 300-500 cycles | 700+ cycles, longer lifespan |

| Cost | Lower upfront cost | Higher initial cost, cost-efficient over time |

| Charging Efficiency | Moderate charging speed | Faster charging capabilities |

| Applications | Automotive, backup power | Portable electronics, renewable energy storage |

Introduction to Lead-Acid and Lead-Free Batteries

Lead-acid batteries, commonly used in automotive and backup power applications, rely on lead dioxide and sponge lead electrodes immersed in sulfuric acid electrolyte, providing reliable energy storage with high surge currents. Lead-free batteries, often based on lithium-ion or nickel-metal hydride chemistries, eliminate toxic lead components, offering lighter weight, longer cycle life, and enhanced environmental safety. Both battery types serve distinct roles, with lead-acid batteries favored for cost-effective power delivery and lead-free alternatives prioritizing sustainability and advanced performance.

Chemical Composition and Material Differences

Lead-acid batteries contain lead dioxide (PbO2) at the positive electrode and metallic lead (Pb) at the negative electrode, submerged in sulfuric acid (H2SO4) electrolyte, enabling electrochemical reactions that store and release energy. Lead-free batteries replace lead components with alternative materials such as lithium-ion or nickel-metal hydride, using electrodes composed of lithium cobalt oxide (LiCoO2) or nickel-metal hydride alloys, which offer improved energy density and reduced environmental toxicity. The chemical composition difference directly influences battery weight, recyclability, and performance characteristics, with lead-acid batteries being heavier but more recyclable and lead-free batteries providing longer cycle life and lower environmental impact.

Energy Density and Performance Comparison

Lead-acid batteries typically offer lower energy density, around 30-50 Wh/kg, compared to lead-free batteries such as lithium-ion, which can exceed 150 Wh/kg, resulting in significantly higher performance efficiency. The higher energy density of lead-free batteries enables longer runtimes and faster charging, making them more suitable for applications requiring compact size and lightweight design. Performance-wise, lead-free batteries demonstrate better cycle life and thermal stability, reducing maintenance and improving reliability over lead-acid counterparts.

Environmental Impact of Lead vs. Lead-Free Batteries

Lead-acid batteries pose significant environmental risks due to the toxicity and persistence of lead, which can contaminate soil and water if improperly disposed of. Lead-free batteries use safer materials, reducing hazardous waste and enhancing recyclability, thus minimizing ecological damage. Shifting to lead-free alternatives aligns with stricter environmental regulations and promotes sustainable battery lifecycle management.

Safety Concerns: Lead Exposure Risks

Lead-acid batteries pose significant safety concerns due to the risk of lead exposure, which can cause serious health issues such as neurological damage and kidney problems. Lead-free batteries eliminate these risks by using alternative materials, ensuring safer handling and disposal. Proper safety protocols and protective equipment are essential when working with lead-acid batteries to minimize lead poisoning hazards.

Recycling and Disposal Challenges

Lead-acid batteries pose significant recycling and disposal challenges due to the toxic lead content, requiring specialized facilities to prevent environmental contamination. Lead-free batteries, often containing lithium or nickel-based compounds, present different waste management issues, including the risk of chemical leakage and the need for advanced recycling technologies to recover valuable materials. Effective recycling protocols are essential for both types to minimize hazardous waste and promote sustainable resource use.

Cost Analysis: Manufacturing and Lifespan

Lead-acid batteries typically have a lower initial manufacturing cost due to the abundance and low price of lead, but their shorter lifespan increases long-term replacement expenses. Lead-free batteries, often utilizing alternative materials like lithium or sodium, incur higher upfront manufacturing costs but benefit from extended cycle life and reduced maintenance, resulting in better cost efficiency over time. Evaluating total cost of ownership requires balancing immediate production expenses against durability and replacement frequency for each battery type.

Applications and Industry Usage

Lead-acid batteries dominate automotive and industrial backup power applications due to their cost-effectiveness and robust performance in high-discharge scenarios. Lead-free batteries, often lithium-ion variants, are increasingly adopted in consumer electronics, electric vehicles, and renewable energy storage for their lightweight, longer cycle life, and environmental benefits. Industries focused on sustainability and advanced technology integration prioritize lead-free solutions, while traditional sectors like automotive and uninterruptible power supply systems still rely heavily on lead-acid technology.

Regulatory Standards and Compliance

Lead-acid batteries must comply with stringent regulatory standards such as the EU Battery Directive and the U.S. EPA Lead Management Regulations, which govern lead content, recycling, and disposal processes to minimize environmental impact. Lead-free batteries, often lithium-based, adhere to different regulations like the RoHS Directive, which restricts hazardous substances but offer greater compliance flexibility due to non-toxic materials. Manufacturers increasingly prefer lead-free alternatives to meet evolving global environmental regulations while reducing hazardous waste and ensuring safer end-of-life battery management.

Future Trends in Battery Technology

Future trends in battery technology emphasize the shift from traditional lead-acid batteries toward advanced lead-free alternatives that offer higher energy density, improved environmental sustainability, and longer lifecycle performance. Innovations in lithium-ion and solid-state battery chemistries are set to disrupt the market by providing safer, lighter, and more efficient energy storage solutions for automotive and stationary applications. Research into scalable, cost-effective manufacturing processes aims to accelerate the adoption of lead-free batteries, aligning with global demands for cleaner energy and reduced heavy metal usage.

Lead-acid battery vs Lead-free battery Infographic

materialdif.com

materialdif.com