Lead ingots offer high density and stability, making them ideal for industrial casting and manufacturing applications, while lead pellets provide versatility and ease of handling for ammunition and ballistic testing. Lead pellets are typically smaller, allowing for more precise control in loading and consistent performance, whereas lead ingots are larger blocks suited for melting and molding processes. Choosing between the two depends on specific project requirements, balancing factors such as size, weight, and handling convenience.

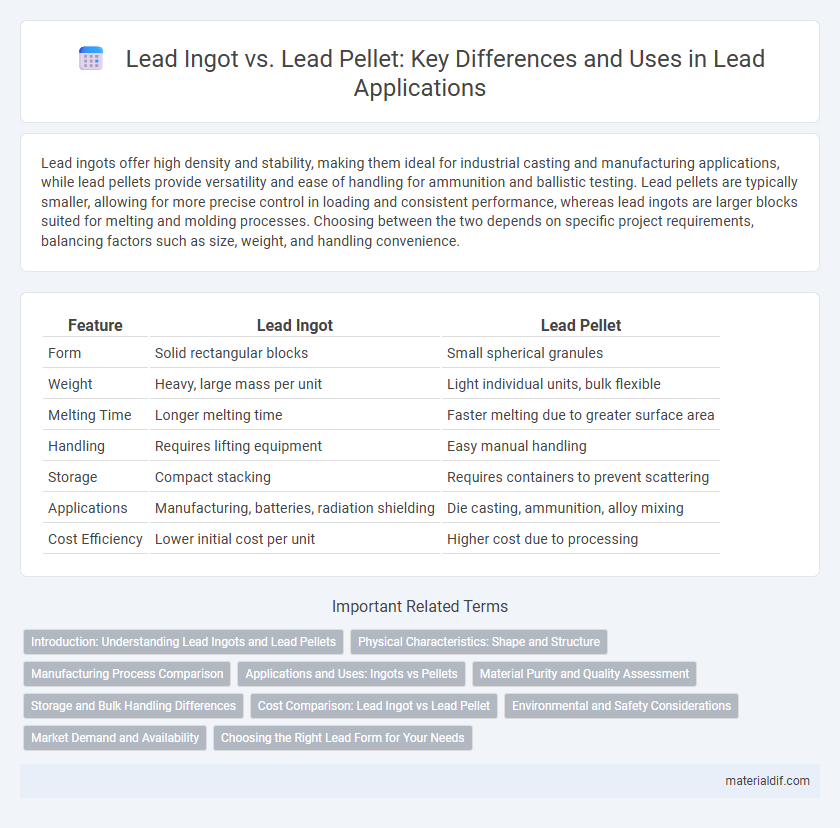

Table of Comparison

| Feature | Lead Ingot | Lead Pellet |

|---|---|---|

| Form | Solid rectangular blocks | Small spherical granules |

| Weight | Heavy, large mass per unit | Light individual units, bulk flexible |

| Melting Time | Longer melting time | Faster melting due to greater surface area |

| Handling | Requires lifting equipment | Easy manual handling |

| Storage | Compact stacking | Requires containers to prevent scattering |

| Applications | Manufacturing, batteries, radiation shielding | Die casting, ammunition, alloy mixing |

| Cost Efficiency | Lower initial cost per unit | Higher cost due to processing |

Introduction: Understanding Lead Ingots and Lead Pellets

Lead ingots are solid blocks of lead typically cast into standardized shapes for ease of transport and storage, commonly used in industrial applications such as battery manufacturing. Lead pellets, on the other hand, are small, rounded particles of lead primarily utilized in ammunition and fishing weights due to their uniform size and density. Both forms offer distinct advantages depending on the requirements for melting, shaping, or direct application in various sectors.

Physical Characteristics: Shape and Structure

Lead ingots are typically rectangular or square blocks with smooth surfaces, designed for efficient stacking and easy transport. Lead pellets have a more rounded, granular shape that facilitates melting and mixing in applications requiring quick uniform distribution. The dense, compact structure of ingots contrasts with the loose, smaller size of pellets, affecting handling and melting rates in industrial processes.

Manufacturing Process Comparison

Lead ingots are produced by melting recycled lead and pouring it into molds, resulting in large, solid blocks primarily used for industrial applications. Lead pellets are formed by casting molten lead into smaller, uniform shapes through specialized pelletizing equipment, enabling precise sizing for ammunition and fishing sinkers. The ingot manufacturing process emphasizes bulk production and purity control, while pellet manufacturing requires stringent shape uniformity and surface finish standards.

Applications and Uses: Ingots vs Pellets

Lead ingots are primarily used in large-scale industrial applications such as battery manufacturing, radiation shielding, and construction due to their dense, uniform shape and ease of storage. Lead pellets, offering greater surface area and faster melting times, are favored in ammunition production, fishing weights, and certain chemical processes. The choice between ingots and pellets depends on specific application requirements, including handling efficiency, melting speed, and material uniformity.

Material Purity and Quality Assessment

Lead ingots typically exhibit higher material purity, often exceeding 99.9% lead content, making them ideal for applications requiring superior conductivity and corrosion resistance. Lead pellets, while convenient for melting and casting, may contain impurities or alloying elements that affect their overall quality and uniformity. Quality assessment of lead products involves rigorous testing for impurity levels, density, and homogeneity to ensure compliance with industry standards and optimal performance in industrial use.

Storage and Bulk Handling Differences

Lead ingots offer greater stability in storage due to their solid, uniform shape, reducing risks of contamination and spillage. Lead pellets, being smaller and more granular, require specialized bulk handling equipment such as hoppers and conveyors to prevent segregation and loss during transport. Both forms demand corrosion-resistant containers and controlled environments to minimize oxidation and ensure safe long-term storage.

Cost Comparison: Lead Ingot vs Lead Pellet

Lead ingots typically offer a lower cost per kilogram compared to lead pellets due to their simplified manufacturing process and reduced handling requirements. Bulk purchasing of lead ingots further decreases expenses, making them more economical for industrial applications where melting and molding are required. Lead pellets, while more convenient for certain uses, often incur higher prices because of additional processing and packaging complexities.

Environmental and Safety Considerations

Lead ingots and lead pellets differ significantly in environmental and safety considerations; lead ingots pose less immediate inhalation risk due to their solid form but require careful handling to prevent heavy metal contamination. Lead pellets, often used in ammunition, can fragment and disperse into ecosystems, increasing the risk of soil and water pollution and toxic exposure to wildlife. Proper storage, disposal, and the use of protective equipment are critical in managing the hazards associated with both lead forms to minimize environmental impact and health risks.

Market Demand and Availability

Lead ingots dominate the market due to their high demand in industrial applications such as battery manufacturing and radiation shielding, where large, consistent quantities of lead are required. Lead pellets, favored in niche markets like ammunition and fishing sinkers, experience variable availability influenced by seasonal demand and raw material supply chains. Market trends indicate a steady increase in lead ingot production driven by automotive and renewable energy sectors, while lead pellet availability remains relatively limited and sensitive to regulatory changes.

Choosing the Right Lead Form for Your Needs

Choosing the right lead form depends on the specific application and handling requirements; lead ingots offer high purity and are ideal for industrial manufacturing and recycling, while lead pellets provide ease of use in precise measurements and ammunition production. Lead ingots typically have a higher density and uniformity, ensuring consistent performance in casting and alloying processes. Lead pellets, being smaller and more manageable, allow for efficient melting and dosing in chemical and laboratory environments.

Lead Ingot vs Lead Pellet Infographic

materialdif.com

materialdif.com