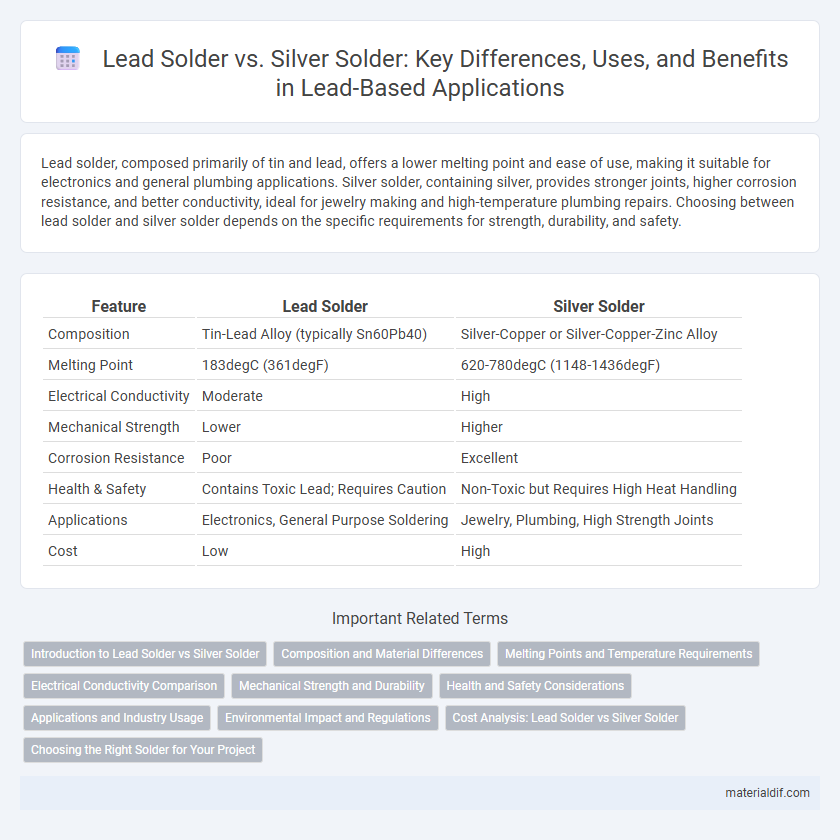

Lead solder, composed primarily of tin and lead, offers a lower melting point and ease of use, making it suitable for electronics and general plumbing applications. Silver solder, containing silver, provides stronger joints, higher corrosion resistance, and better conductivity, ideal for jewelry making and high-temperature plumbing repairs. Choosing between lead solder and silver solder depends on the specific requirements for strength, durability, and safety.

Table of Comparison

| Feature | Lead Solder | Silver Solder |

|---|---|---|

| Composition | Tin-Lead Alloy (typically Sn60Pb40) | Silver-Copper or Silver-Copper-Zinc Alloy |

| Melting Point | 183degC (361degF) | 620-780degC (1148-1436degF) |

| Electrical Conductivity | Moderate | High |

| Mechanical Strength | Lower | Higher |

| Corrosion Resistance | Poor | Excellent |

| Health & Safety | Contains Toxic Lead; Requires Caution | Non-Toxic but Requires High Heat Handling |

| Applications | Electronics, General Purpose Soldering | Jewelry, Plumbing, High Strength Joints |

| Cost | Low | High |

Introduction to Lead Solder vs Silver Solder

Lead solder, composed primarily of tin and lead, is widely used for its low melting point and excellent wetting properties, making it ideal for electrical and plumbing applications. Silver solder, containing silver alongside copper and zinc, offers higher strength and temperature resistance, suitable for metal joining in HVAC and jewelry making. Choosing between lead solder and silver solder depends on factors like mechanical strength requirements, thermal conductivity, and health safety considerations due to lead toxicity.

Composition and Material Differences

Lead solder primarily consists of a tin-lead alloy, typically with 60% tin and 40% lead, offering low melting points around 183degC for easy soldering. Silver solder, often containing a higher percentage of silver (up to 50%) along with copper and zinc, has a higher melting temperature ranging from 600degC to 800degC, providing stronger joints and better thermal and electrical conductivity. The material differences lead to distinct applications: lead solder is common in electronics for delicate components, while silver solder is favored in plumbing and metalwork for durability and corrosion resistance.

Melting Points and Temperature Requirements

Lead solder typically melts around 183degC (361degF), making it suitable for low-temperature applications and delicate electronic components. Silver solder, with melting points ranging from 620degC to 780degC (1148degF to 1436degF), is preferred for high-strength joints and requires significantly higher temperatures for soldering. These melting point differences dictate the choice of solder based on application-specific temperature requirements and material compatibility.

Electrical Conductivity Comparison

Lead solder typically offers electrical conductivity around 8.8 MS/m, while silver solder's conductivity can exceed 25 MS/m due to its higher silver content. The superior conductivity of silver solder makes it ideal for high-performance electronic applications requiring efficient current flow. Despite lead solder's widespread use, silver solder's enhanced electrical properties provide significant advantages in precision circuitry and critical connections.

Mechanical Strength and Durability

Lead solder typically offers moderate mechanical strength suitable for electronic applications, but it lacks the high tensile strength and durability found in silver solder. Silver solder provides superior mechanical strength, with tensile strengths often exceeding 50,000 psi, making it ideal for heavy-duty joints and high-stress environments. Its enhanced durability resists fatigue and thermal cycling better than lead solder, ensuring longer-lasting, reliable connections in demanding mechanical and industrial settings.

Health and Safety Considerations

Lead solder contains toxic lead that poses serious health risks including lead poisoning, neurological damage, and reproductive harm, requiring strict ventilation and protective measures during use. Silver solder, often lead-free and composed mainly of silver, copper, and sometimes zinc, offers a safer alternative with lower toxicity but still demands caution due to fumes generated when heated. Proper personal protective equipment (PPE) and adherence to occupational safety standards are essential to minimize health hazards in soldering processes.

Applications and Industry Usage

Lead solder remains widely used in electronics manufacturing due to its excellent electrical conductivity, low melting point, and cost-effectiveness, making it ideal for circuit board assembly and electrical connections. Silver solder, enriched with silver content ranging from 15% to 30%, is preferred in plumbing, jewelry, and aerospace industries for its superior strength, corrosion resistance, and ability to withstand high temperatures. Industries requiring durable, high-performance joints under mechanical stress, such as automotive and HVAC sectors, favor silver solder for its enhanced mechanical properties compared to lead solder.

Environmental Impact and Regulations

Lead solder poses significant environmental hazards due to its toxic lead content, which can contaminate soil and water, leading to strict regulations such as the RoHS directive restricting its use in electronics. Silver solder, containing less harmful metals like silver and copper, presents a lower environmental impact and is often preferred to comply with eco-friendly regulations and reduce hazardous waste. Despite silver solder being more expensive, its compliance with global environmental standards makes it a sustainable alternative to lead-based solders.

Cost Analysis: Lead Solder vs Silver Solder

Lead solder typically costs significantly less than silver solder, making it a budget-friendly choice for large-scale electronics manufacturing. Silver solder, containing precious metals like silver and copper, commands a higher price due to its enhanced mechanical strength and superior thermal conductivity. Cost analysis must weigh the upfront savings of lead solder against potential long-term benefits of silver solder in durability and performance.

Choosing the Right Solder for Your Project

Choosing the right solder depends on the specific requirements of your project, with lead solder offering excellent electrical conductivity and ease of use for electronics, while silver solder provides superior strength and corrosion resistance ideal for plumbing and metalwork. Lead solder melts at a lower temperature, making it suitable for delicate components, whereas silver solder's higher melting point ensures durable, high-temperature joints. Consider factors such as thermal sensitivity, mechanical stress, and regulatory restrictions to determine whether lead or silver solder best meets your project's performance and safety needs.

Lead Solder vs Silver Solder Infographic

materialdif.com

materialdif.com