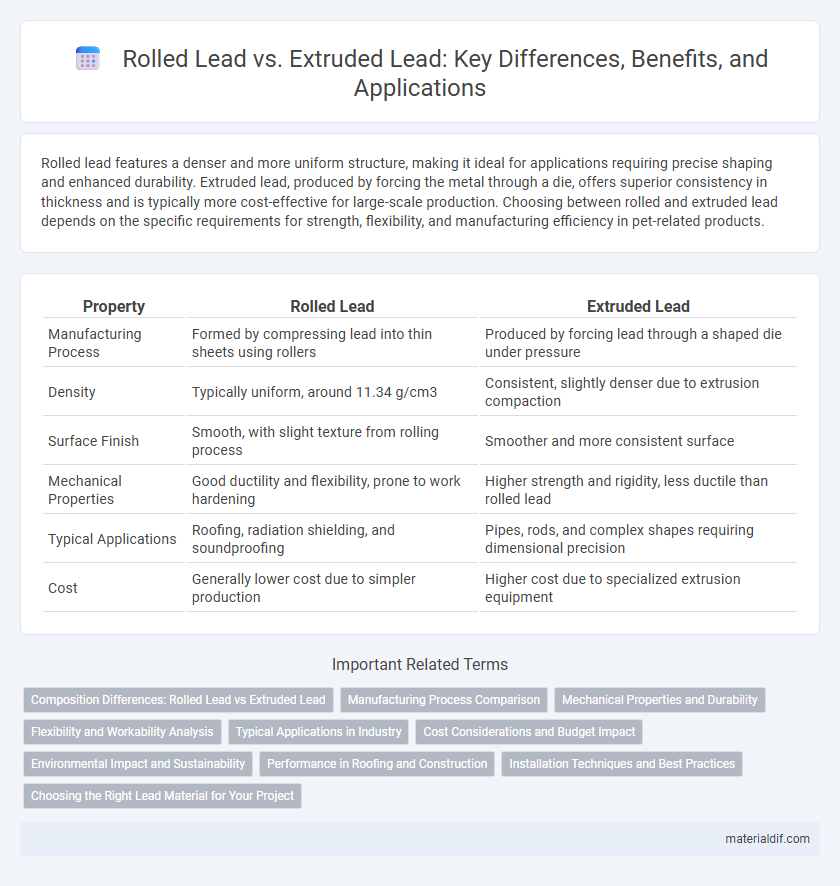

Rolled lead features a denser and more uniform structure, making it ideal for applications requiring precise shaping and enhanced durability. Extruded lead, produced by forcing the metal through a die, offers superior consistency in thickness and is typically more cost-effective for large-scale production. Choosing between rolled and extruded lead depends on the specific requirements for strength, flexibility, and manufacturing efficiency in pet-related products.

Table of Comparison

| Property | Rolled Lead | Extruded Lead |

|---|---|---|

| Manufacturing Process | Formed by compressing lead into thin sheets using rollers | Produced by forcing lead through a shaped die under pressure |

| Density | Typically uniform, around 11.34 g/cm3 | Consistent, slightly denser due to extrusion compaction |

| Surface Finish | Smooth, with slight texture from rolling process | Smoother and more consistent surface |

| Mechanical Properties | Good ductility and flexibility, prone to work hardening | Higher strength and rigidity, less ductile than rolled lead |

| Typical Applications | Roofing, radiation shielding, and soundproofing | Pipes, rods, and complex shapes requiring dimensional precision |

| Cost | Generally lower cost due to simpler production | Higher cost due to specialized extrusion equipment |

Composition Differences: Rolled Lead vs Extruded Lead

Rolled lead typically contains higher tin content, enhancing its hardness and resistance to deformation, while extruded lead has a purer composition with minimal additives, resulting in greater malleability. The alloy composition in rolled lead often includes trace metals like antimony or arsenic, improving mechanical strength for structural applications. Extruded lead's simpler composition makes it ideal for applications requiring high ductility and ease of shaping, such as cable sheathing or radiation shielding.

Manufacturing Process Comparison

Rolled lead is produced by compressing lead slabs between rollers to achieve a thin, flat sheet with uniform thickness, optimizing surface smoothness and structural consistency. Extruded lead involves forcing heated lead through a die to create specific shapes or profiles, enhancing mechanical strength and dimensional precision. While rolling prioritizes surface finish and flatness, extrusion enables more complex cross-sectional designs suitable for specialized industrial applications.

Mechanical Properties and Durability

Rolled lead exhibits superior tensile strength and hardness due to work hardening during the rolling process, enhancing its mechanical durability compared to extruded lead. Extruded lead, characterized by a more uniform microstructure, offers better ductility and resistance to cracking under stress, making it preferable for applications requiring flexibility. Both forms provide excellent corrosion resistance, but rolled lead's improved fatigue resistance contributes to a longer lifespan in structural and shielding applications.

Flexibility and Workability Analysis

Rolled lead exhibits superior flexibility due to its grain structure developed through the rolling process, making it ideal for applications requiring bending and shaping without cracking. Extruded lead, while offering consistent cross-sectional dimensions, tends to be less flexible but provides enhanced surface finish and precise tolerances. The workability of rolled lead excels in forming operations, whereas extruded lead is preferred for components demanding uniformity and dimensional accuracy.

Typical Applications in Industry

Rolled lead is predominantly used in radiation shielding for medical and nuclear industries due to its uniform thickness and ease of fabrication into sheets and plates. Extruded lead finds applications in corrosion resistance and battery grids because of its improved mechanical strength and ability to be formed into complex profiles. Both forms are essential in industrial sectors requiring durable and adaptable lead materials tailored to specific performance needs.

Cost Considerations and Budget Impact

Rolled lead typically offers lower production costs due to simpler manufacturing processes and reduced material waste, making it a cost-effective option for large-scale applications. Extruded lead, while more expensive due to specialized equipment and higher energy consumption, provides superior material consistency and strength, potentially reducing long-term maintenance expenses. Budget impact analysis should weigh initial outlays against durability benefits, with rolled lead favoring upfront savings and extruded lead promising cost efficiency over the product lifecycle.

Environmental Impact and Sustainability

Rolled lead production typically generates less waste and consumes less energy compared to extruded lead, making it a more environmentally sustainable option. Extruded lead processes often involve higher emissions and greater resource use due to the intensive heating and shaping required. Choosing rolled lead supports reduced carbon footprints and enhanced sustainability in lead manufacturing industries.

Performance in Roofing and Construction

Rolled lead offers superior tensile strength and flexibility, making it ideal for intricate roofing shapes and weatherproofing applications that require precise molding. Extruded lead provides consistent thickness and density, ensuring enhanced durability and long-term resistance to corrosion in construction projects. Both materials deliver excellent performance, but rolled lead excels in adaptability while extruded lead prioritizes structural reliability.

Installation Techniques and Best Practices

Rolled lead offers superior flexibility and is ideal for applications requiring tight bends and intricate detailing, making it easier to shape during installation without cracking. Extruded lead, characterized by its uniform thickness and higher density, provides enhanced durability and corrosion resistance, suited for projects demanding long-term stability and minimal maintenance. Best practices include selecting rolled lead for detailed flashing work and extruded lead for roofing components exposed to heavy wear, ensuring precise adherence with compatible soldering and sealing techniques to optimize performance.

Choosing the Right Lead Material for Your Project

Rolled lead offers superior flexibility and better surface finish, making it ideal for roofing and flashing applications where malleability is crucial. Extruded lead provides higher structural strength and dimensional stability, suitable for profiles and custom shapes that require precise, consistent cross-sections. Selecting between rolled and extruded lead depends on the specific project demands, balancing flexibility with strength for optimal performance and durability.

Rolled lead vs Extruded lead Infographic

materialdif.com

materialdif.com