Lead foil and lead sheet differ primarily in thickness, with lead foil being significantly thinner and more flexible, making it ideal for applications requiring lightweight, pliable protection such as radiation shielding in medical devices and electronics. Lead sheet, thicker and more rigid, provides robust durability and structural support, often used in construction, roofing, and industrial settings where strength and resistance to impact are critical. Choosing between lead foil and lead sheet depends on the specific requirements for flexibility, weight, and strength in the intended use.

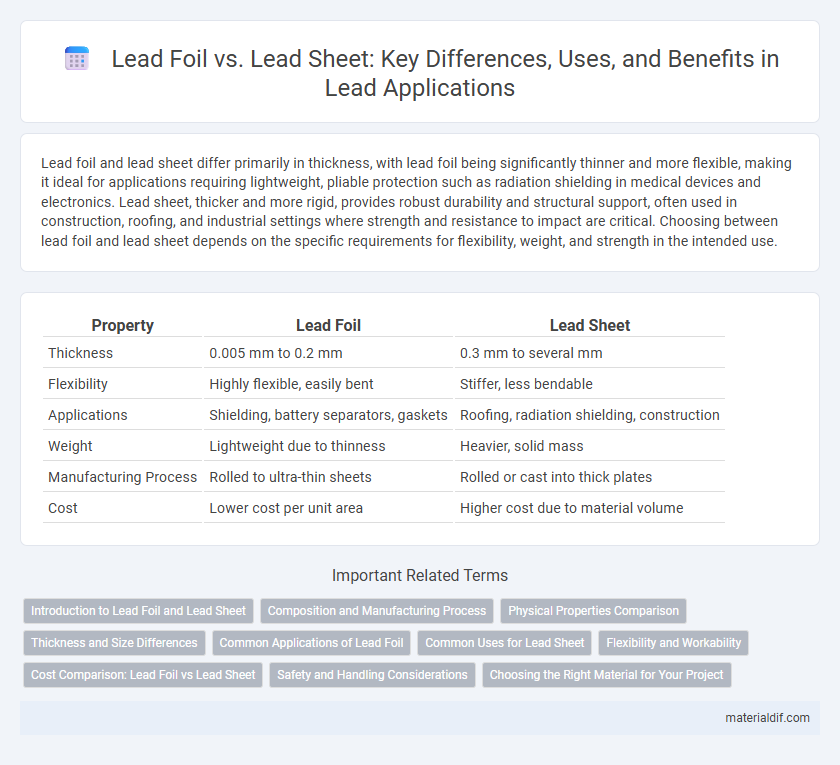

Table of Comparison

| Property | Lead Foil | Lead Sheet |

|---|---|---|

| Thickness | 0.005 mm to 0.2 mm | 0.3 mm to several mm |

| Flexibility | Highly flexible, easily bent | Stiffer, less bendable |

| Applications | Shielding, battery separators, gaskets | Roofing, radiation shielding, construction |

| Weight | Lightweight due to thinness | Heavier, solid mass |

| Manufacturing Process | Rolled to ultra-thin sheets | Rolled or cast into thick plates |

| Cost | Lower cost per unit area | Higher cost due to material volume |

Introduction to Lead Foil and Lead Sheet

Lead foil and lead sheet are both thin layers of pure lead used for shielding and protective applications, with lead foil being thinner and more flexible than lead sheet. Lead foil typically measures less than 0.15 mm in thickness, making it ideal for wrapping, cushioning, and light radiation shielding, while lead sheet ranges from 0.15 mm to several millimeters thick, offering enhanced durability and structural support. The choice between lead foil and lead sheet depends on requirements for flexibility, thickness, and protective strength in industrial, medical, and construction uses.

Composition and Manufacturing Process

Lead foil typically measures less than 0.2 millimeters in thickness, made by rolling pure lead or lead alloys to achieve high ductility and pliability, which makes it suitable for wrapping and shielding applications. Lead sheets, thicker than 0.2 millimeters, are produced through casting or rolling processes involving pure lead or specialized lead alloys, enhancing structural strength for industrial uses such as radiation shielding or roofing. The manufacturing processes differ mainly in the degree of rolling and heat treatment, influencing the material's mechanical properties and intended applications.

Physical Properties Comparison

Lead foil is notably thinner, typically ranging from 0.01 to 0.2 millimeters, offering higher flexibility and ease of molding compared to lead sheet, which generally measures 0.2 millimeters and above, providing greater rigidity and structural strength. The density of both materials remains consistent at approximately 11.34 grams per cubic centimeter, but lead sheet's increased thickness results in enhanced durability and superior resistance to mechanical stress. Thermal conductivity is similar in both forms, around 35.3 W/m*K, though lead foil's reduced thickness allows for faster heat dissipation in applications requiring rapid thermal response.

Thickness and Size Differences

Lead foil is typically much thinner, measuring between 0.1 mm to 0.3 mm in thickness, making it ideal for applications requiring flexibility and lightweight shielding. Lead sheets generally range from 0.4 mm to several millimeters thick, offering greater durability and structural support for more robust construction or radiation protection needs. The size of lead sheets tends to be larger, commonly available in standard dimensions such as 1 m x 2 m or 1.22 m x 2.44 m, while lead foil is often supplied in smaller rolls or thin sheets tailored for precise, thin layering.

Common Applications of Lead Foil

Lead foil, known for its thinness and flexibility compared to lead sheet, is commonly applied in radiation shielding for medical and nuclear industries, offering effective protection in compact spaces. It also serves in battery manufacturing, providing conductive layers due to its excellent electrochemical properties. Additionally, lead foil is used in industrial sealing and soundproofing, benefiting from its malleability and density.

Common Uses for Lead Sheet

Lead sheet is commonly used in radiation shielding, roofing, and soundproofing due to its malleability and density. Its durability makes it ideal for waterproofing applications and protective barriers in construction and industrial settings. Lead foil, being thinner and more flexible, is typically reserved for light wrapping and decorative purposes rather than heavy-duty construction.

Flexibility and Workability

Lead foil offers superior flexibility compared to lead sheet, making it ideal for applications requiring intricate shaping and tight wrapping around complex surfaces. Lead sheet, typically thicker, provides greater structural strength but less workability, limiting its use in projects that demand precise contouring. The choice between lead foil and lead sheet depends on the balance needed between pliability and durability in specific construction or fabrication tasks.

Cost Comparison: Lead Foil vs Lead Sheet

Lead foil is significantly thinner and less dense than lead sheet, resulting in lower material costs for applications requiring minimal thickness. Lead sheet, being thicker and heavier, incurs higher raw material expenses but offers enhanced durability and protection. Cost comparison typically favors lead foil for lightweight, budget-sensitive projects, while lead sheet is preferred when structural integrity and longevity justify the additional expense.

Safety and Handling Considerations

Lead foil offers greater flexibility and ease of wrapping small or irregularly shaped objects, but its thinness requires careful handling to avoid tearing and exposure to lead dust. Lead sheet, being thicker and more rigid, provides enhanced durability and better protection against physical damage, reducing the risk of contamination from lead particles. Proper safety measures, including wearing gloves and working in well-ventilated areas, are essential for both forms to minimize lead exposure and prevent health hazards.

Choosing the Right Material for Your Project

Lead foil offers exceptional flexibility and a thinner profile, ideal for precise applications requiring tight bends or intricate shapes. Lead sheets provide greater thickness and durability, making them suitable for heavy-duty projects demanding enhanced protection or structural support. Selecting the right material depends on project specifications, balancing factors such as thickness, flexibility, and durability to ensure optimal performance.

Lead foil vs Lead sheet Infographic

materialdif.com

materialdif.com