Lead offers superior density and weight compared to aluminum, making it an ideal choice for applications requiring high mass in a compact form. Aluminum is favored for its lightweight and corrosion resistance but lacks the heft needed for precise balancing or shielding purposes. Choosing between lead and aluminum depends on whether weight or durability is the primary concern in the specific use case.

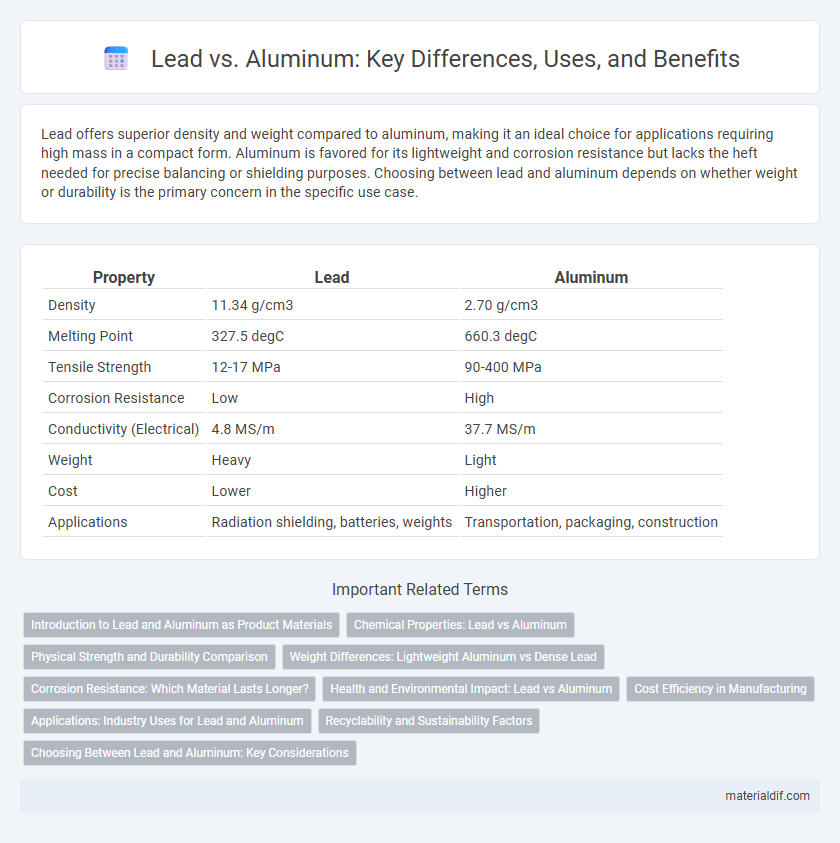

Table of Comparison

| Property | Lead | Aluminum |

|---|---|---|

| Density | 11.34 g/cm3 | 2.70 g/cm3 |

| Melting Point | 327.5 degC | 660.3 degC |

| Tensile Strength | 12-17 MPa | 90-400 MPa |

| Corrosion Resistance | Low | High |

| Conductivity (Electrical) | 4.8 MS/m | 37.7 MS/m |

| Weight | Heavy | Light |

| Cost | Lower | Higher |

| Applications | Radiation shielding, batteries, weights | Transportation, packaging, construction |

Introduction to Lead and Aluminum as Product Materials

Lead, a dense and malleable metal known for its corrosion resistance and soundproofing qualities, is commonly used in batteries, radiation shielding, and construction materials. Aluminum, lightweight and highly conductive, excels in applications requiring strength-to-weight efficiency such as aerospace, packaging, and automotive industries. Both metals offer unique properties that influence their selection based on factors like durability, weight, and environmental impact.

Chemical Properties: Lead vs Aluminum

Lead has a higher atomic number (82) compared to aluminum (13), resulting in greater atomic mass and density. Chemically, lead is more inert and resistant to corrosion due to the formation of a stable oxide layer, while aluminum forms a protective aluminum oxide film that prevents further oxidation. Lead's chemical reactivity is lower, exhibiting poor affinity for oxygen compared to the highly reactive aluminum, which readily oxidizes and reacts with acids and alkalis.

Physical Strength and Durability Comparison

Lead exhibits higher density and malleability but lower tensile strength compared to aluminum, making it less resistant to deformation under stress. Aluminum boasts superior physical strength with a tensile strength ranging from 70 to 700 MPa, while lead typically measures around 12 to 18 MPa. In terms of durability, aluminum's resistance to corrosion and fatigue extends its lifespan in structural applications, contrasting with lead's susceptibility to surface oxidation and fatigue cracking.

Weight Differences: Lightweight Aluminum vs Dense Lead

Aluminum weighs approximately 2.7 grams per cubic centimeter, making it significantly lighter than lead, which has a density of about 11.34 grams per cubic centimeter. This weight difference means aluminum is preferred in applications requiring lightweight materials, such as aerospace and automotive industries. Conversely, lead's high density is ideal for radiation shielding and soundproofing, where weight is less critical.

Corrosion Resistance: Which Material Lasts Longer?

Lead exhibits exceptional corrosion resistance in harsh environments, particularly against acids and salts, making it ideal for applications where longevity is critical. Aluminum forms a protective oxide layer that guards against corrosion, but it can degrade faster in highly alkaline or acidic conditions. Overall, lead's superior resistance to chemical corrosion often results in a longer lifespan compared to aluminum in aggressive environments.

Health and Environmental Impact: Lead vs Aluminum

Lead poses significant health risks due to its toxicity, causing neurological damage and developmental issues, while aluminum is generally considered less harmful but can accumulate in the body over time with potential neurotoxic effects. Environmentally, lead contaminates soil and water, persisting for decades and entering food chains, whereas aluminum production generates greenhouse gases and contributes to habitat destruction but is more recyclable with fewer long-term contamination concerns. Choosing aluminum over lead reduces toxic exposure risks and environmental persistence, favoring safer health and ecological outcomes.

Cost Efficiency in Manufacturing

Lead offers lower raw material costs compared to aluminum, making it more cost-effective for manufacturing applications requiring dense materials. Its ease of casting and machinability reduces production time and tooling expenses, enhancing overall manufacturing efficiency. However, aluminum's lightweight properties and corrosion resistance can lead to longer-term savings in transportation and maintenance despite higher initial costs.

Applications: Industry Uses for Lead and Aluminum

Lead is extensively used in battery manufacturing, radiation shielding, and cable sheathing due to its high density and corrosion resistance. Aluminum finds wide applications in aerospace, automotive, and packaging industries because of its lightweight, high strength-to-weight ratio, and excellent corrosion resistance. Both metals serve critical roles in construction, with lead often used for roofing and soundproofing, while aluminum is favored for structural frameworks and window frames.

Recyclability and Sustainability Factors

Lead features a high recyclability rate, with over 90% of lead products being recycled, reducing the need for mining and minimizing environmental impact. Aluminum exceeds lead in sustainability due to its lighter weight, lower toxicity, and almost infinite recyclability, requiring only 5% of the energy used for primary production when recycled. Both metals support circular economies, but aluminum's superior energy efficiency and non-toxic properties make it the preferred choice for eco-friendly applications.

Choosing Between Lead and Aluminum: Key Considerations

Lead offers superior density and radiation shielding, making it ideal for applications requiring heavy protection and soundproofing. Aluminum provides lightweight strength, corrosion resistance, and better thermal conductivity, suitable for aerospace and automotive industries. Key considerations include weight constraints, environmental impact, cost, and material durability in specific use cases.

Lead vs Aluminum Infographic

materialdif.com

materialdif.com