Lead is denser and softer than steel, making it more malleable and easier to shape for specific applications. Steel, on the other hand, offers superior tensile strength and durability, ideal for high-stress environments. When choosing between lead and steel, consider lead's corrosion resistance versus steel's mechanical robustness.

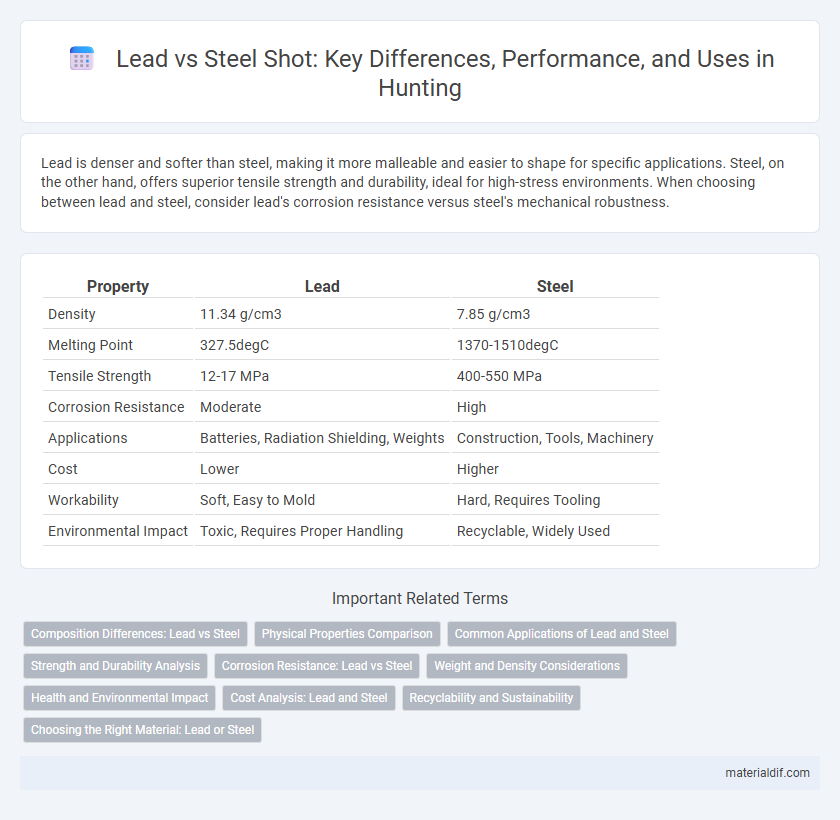

Table of Comparison

| Property | Lead | Steel |

|---|---|---|

| Density | 11.34 g/cm3 | 7.85 g/cm3 |

| Melting Point | 327.5degC | 1370-1510degC |

| Tensile Strength | 12-17 MPa | 400-550 MPa |

| Corrosion Resistance | Moderate | High |

| Applications | Batteries, Radiation Shielding, Weights | Construction, Tools, Machinery |

| Cost | Lower | Higher |

| Workability | Soft, Easy to Mold | Hard, Requires Tooling |

| Environmental Impact | Toxic, Requires Proper Handling | Recyclable, Widely Used |

Composition Differences: Lead vs Steel

Lead primarily consists of the element Pb (lead) with a dense atomic structure, while steel is an alloy composed mainly of iron (Fe) combined with carbon (C) and varying amounts of other elements such as manganese, chromium, and nickel to enhance strength and corrosion resistance. Lead's composition results in a soft, malleable metal with low tensile strength, whereas steel's iron-carbon matrix provides high tensile strength and durability. The significant compositional differences between lead and steel directly influence their mechanical properties and applications in construction and manufacturing industries.

Physical Properties Comparison

Lead exhibits a density of approximately 11.34 g/cm3, significantly higher than steel's typical range of 7.75 to 8.05 g/cm3, contributing to its heavier weight per volume. The softness of lead with a Mohs hardness around 1.5 contrasts sharply with steel's hardness, which ranges from 4 to 8 depending on alloy composition and treatment. Lead's melting point at 327.5degC is substantially lower than steel's melting range of 1370degC to 1510degC, influencing their applications based on thermal resistance requirements.

Common Applications of Lead and Steel

Lead is commonly used in radiation shielding, batteries, and plumbing due to its high density and corrosion resistance, making it ideal for protecting against X-rays and chemical exposure. Steel finds widespread applications in construction, automotive manufacturing, and heavy machinery because of its exceptional strength, durability, and versatility. Both materials serve critical roles in industrial and structural contexts, with lead preferred for protective uses and steel favored for load-bearing and structural components.

Strength and Durability Analysis

Lead exhibits significantly lower tensile strength and hardness compared to steel, resulting in limited load-bearing capacity and structural integrity. Steel's high carbon content and alloying elements enhance its strength and durability, making it ideal for construction and heavy-duty applications. The corrosion resistance of certain steel grades further extends their lifespan, whereas lead is more susceptible to deformation and environmental degradation.

Corrosion Resistance: Lead vs Steel

Lead exhibits superior corrosion resistance compared to steel due to its natural ability to form a protective oxide layer that prevents further degradation. Steel, especially when untreated, is prone to rust and corrosion when exposed to moisture and oxygen, leading to structural weakening over time. This inherent difference makes lead an ideal choice for applications requiring long-term exposure to corrosive environments.

Weight and Density Considerations

Lead has a density of approximately 11.34 g/cm3, making it significantly heavier than steel, which has a density around 7.85 g/cm3. This higher density means lead provides greater mass in a smaller volume, essential for applications requiring compact weight solutions. Steel's lower density results in lighter structures, favorable when strength-to-weight ratio and rigidity are priorities.

Health and Environmental Impact

Lead exposure poses significant health risks, including neurological damage and toxicity, particularly in children, while steel is generally considered safer with minimal toxic effects. Environmentally, lead mining and processing contaminate soil and water, causing long-term ecological harm; steel production emits considerable CO2 but offers better recyclability and lower environmental persistence. Choosing steel over lead reduces human health hazards and supports more sustainable environmental management practices.

Cost Analysis: Lead and Steel

Lead typically costs more per ton compared to common structural steel varieties but offers advantages in density and corrosion resistance that can reduce overall project expenses. Steel prices vary widely depending on grade and market fluctuations, often making it more cost-effective for large-scale structural applications. Lead's higher raw material cost is offset by lower maintenance and replacement costs in specific environments such as marine or chemical settings.

Recyclability and Sustainability

Lead offers superior recyclability compared to steel, with recycling rates exceeding 90% due to its ability to be reused without quality loss, making it highly sustainable for battery and radiation shielding applications. Steel recycling, while also sustainable, typically achieves lower rates and requires more energy-intensive processing to maintain integrity. The higher recyclability of lead contributes significantly to reducing mining impacts and conserving natural resources, enhancing its role in circular economy strategies.

Choosing the Right Material: Lead or Steel

Lead offers superior corrosion resistance and malleability, making it ideal for applications requiring easy shaping and environmental protection, while steel provides greater tensile strength and durability suitable for structural support and heavy-load bearing. Consider lead for shielding in radiation protection or soundproofing, whereas steel is preferred in construction and manufacturing for its robustness and longevity. Selecting between lead and steel depends on balancing factors like strength requirements, environmental exposure, weight constraints, and cost efficiency.

Lead vs Steel Infographic

materialdif.com

materialdif.com