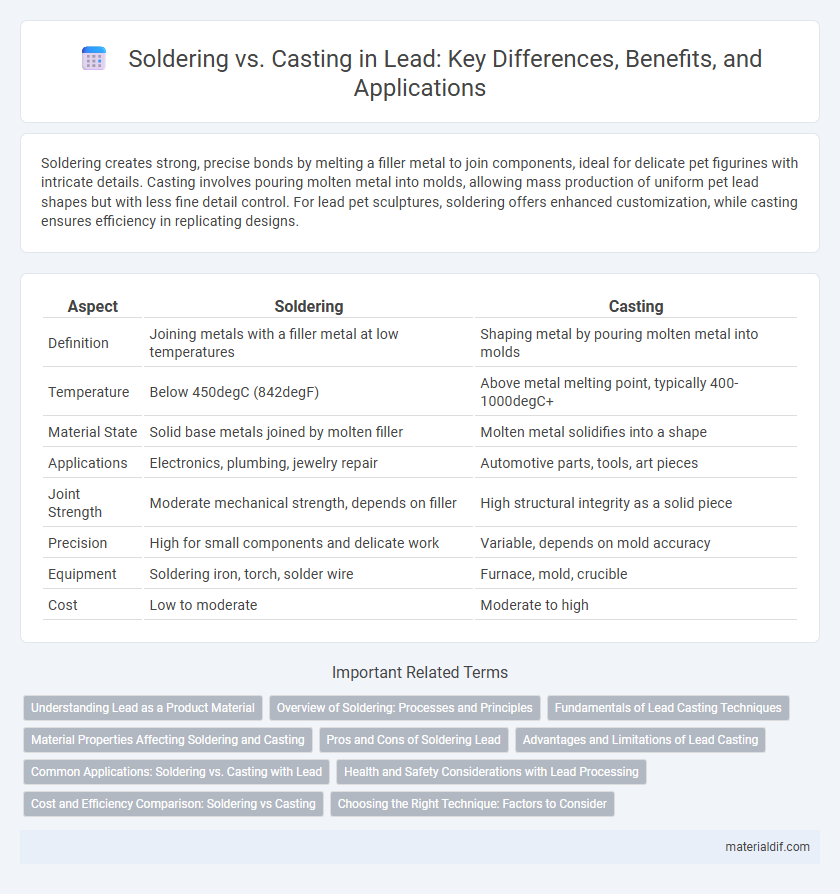

Soldering creates strong, precise bonds by melting a filler metal to join components, ideal for delicate pet figurines with intricate details. Casting involves pouring molten metal into molds, allowing mass production of uniform pet lead shapes but with less fine detail control. For lead pet sculptures, soldering offers enhanced customization, while casting ensures efficiency in replicating designs.

Table of Comparison

| Aspect | Soldering | Casting |

|---|---|---|

| Definition | Joining metals with a filler metal at low temperatures | Shaping metal by pouring molten metal into molds |

| Temperature | Below 450degC (842degF) | Above metal melting point, typically 400-1000degC+ |

| Material State | Solid base metals joined by molten filler | Molten metal solidifies into a shape |

| Applications | Electronics, plumbing, jewelry repair | Automotive parts, tools, art pieces |

| Joint Strength | Moderate mechanical strength, depends on filler | High structural integrity as a solid piece |

| Precision | High for small components and delicate work | Variable, depends on mold accuracy |

| Equipment | Soldering iron, torch, solder wire | Furnace, mold, crucible |

| Cost | Low to moderate | Moderate to high |

Understanding Lead as a Product Material

Lead's unique properties, such as high density, low melting point of 327.5degC, and excellent corrosion resistance, make it suitable for both soldering and casting applications. In soldering, lead alloys provide strong, conductive joints ideal for electrical components, while in casting, lead's fluidity and ability to fill molds precisely are crucial for producing detailed shapes. Understanding lead's toxicity is essential for safe handling, with regulations limiting its use in consumer products to minimize health risks.

Overview of Soldering: Processes and Principles

Soldering involves joining metal parts by melting a filler metal, known as solder, which has a lower melting point than the base metals, ensuring minimal damage to the components. The process requires precise temperature control, typically between 180degC and 250degC, to create strong, conductive, and corrosion-resistant joints without melting the primary materials. Key principles include wetting, capillary action, and the use of flux to prevent oxidation and improve the solder's flow and adherence.

Fundamentals of Lead Casting Techniques

Lead casting techniques rely on the metal's low melting point of 327.5degC, allowing precise mold formation and solidification control. Mastery of temperature regulation and mold design ensures uniform lead distribution and reduces porosity defects. Understanding lead's fluidity and cooling rate is essential for producing high-quality, detailed castings in various industrial applications.

Material Properties Affecting Soldering and Casting

Lead's low melting point and excellent thermal conductivity enhance soldering efficiency by allowing precise temperature control and rapid heat transfer, which minimizes component damage. In casting, lead's high density and fluidity enable smooth mold filling and detailed replication of complex shapes, while its softness facilitates easy machining post-casting. The distinct material properties, including lead's resistance to corrosion and tensile strength, critically influence the choice between soldering for electronic joins and casting for structural applications.

Pros and Cons of Soldering Lead

Soldering lead provides precise control and strong mechanical connections ideal for delicate electronics, offering excellent conductivity and ease of repair compared to casting. However, soldering can introduce flux residues that require cleaning and may produce weaker joints if not executed with proper temperature control, potentially leading to stress fractures. Its lower melting point enables quick assembly but limits exposure to high-temperature environments, making it less suitable for heavy-duty structural applications than casting.

Advantages and Limitations of Lead Casting

Lead casting offers excellent moldability and high density, making it ideal for detailed and durable components in industries like plumbing and radiation shielding. However, limitations include lead's toxicity, requiring careful handling and ventilation controls to prevent health hazards. Its relatively low melting point facilitates ease of casting but restricts applications in high-temperature environments.

Common Applications: Soldering vs. Casting with Lead

Lead soldering is commonly used in electronics for creating reliable electrical connections and assembling circuit boards due to its low melting point and excellent conductivity. Lead casting is frequently applied in manufacturing fishing weights, radiation shielding, and specialized industrial components requiring dense, durable metal parts. Both techniques exploit lead's unique properties but serve distinct purposes: soldering for precision joining and casting for forming solid, heavy-duty objects.

Health and Safety Considerations with Lead Processing

Soldering lead involves exposure to lead fumes and dust, which pose inhalation and ingestion risks, necessitating proper ventilation and protective equipment to minimize lead poisoning. Casting lead generates airborne lead particles and requires temperature control to prevent burns and toxic exposure, making the use of gloves, respirators, and workspace containment essential. Regular monitoring of blood lead levels and strict hygiene practices reduce the risk of chronic lead toxicity during both soldering and casting operations.

Cost and Efficiency Comparison: Soldering vs Casting

Soldering offers lower initial equipment costs and faster setup times, making it more cost-effective for small-scale or precision projects. Casting requires higher upfront investment in molds and materials but achieves greater efficiency and lower per-unit costs in large production runs due to faster batch processing. Evaluating production volume and complexity is essential for choosing between the cost-effective precision of soldering and the scalable efficiency of casting.

Choosing the Right Technique: Factors to Consider

Selecting between soldering and casting for lead work depends on factors like the complexity of the design, desired strength, and production volume. Soldering suits precision joints and small-scale repairs, providing strong bonds without melting the base metal. Casting excels in creating intricate shapes and large quantities by melting and molding lead into detailed forms.

Soldering vs Casting Infographic

materialdif.com

materialdif.com