Lead-acid batteries are heavier and have a shorter lifespan compared to lithium-ion batteries, which offer higher energy density and longer cycle life, making them ideal for modern applications. While lead-acid batteries are more affordable upfront, lithium-ion batteries provide better efficiency, faster charging, and require less maintenance over time. Choosing between lead-acid and lithium-ion depends largely on budget, weight considerations, and energy requirements.

Table of Comparison

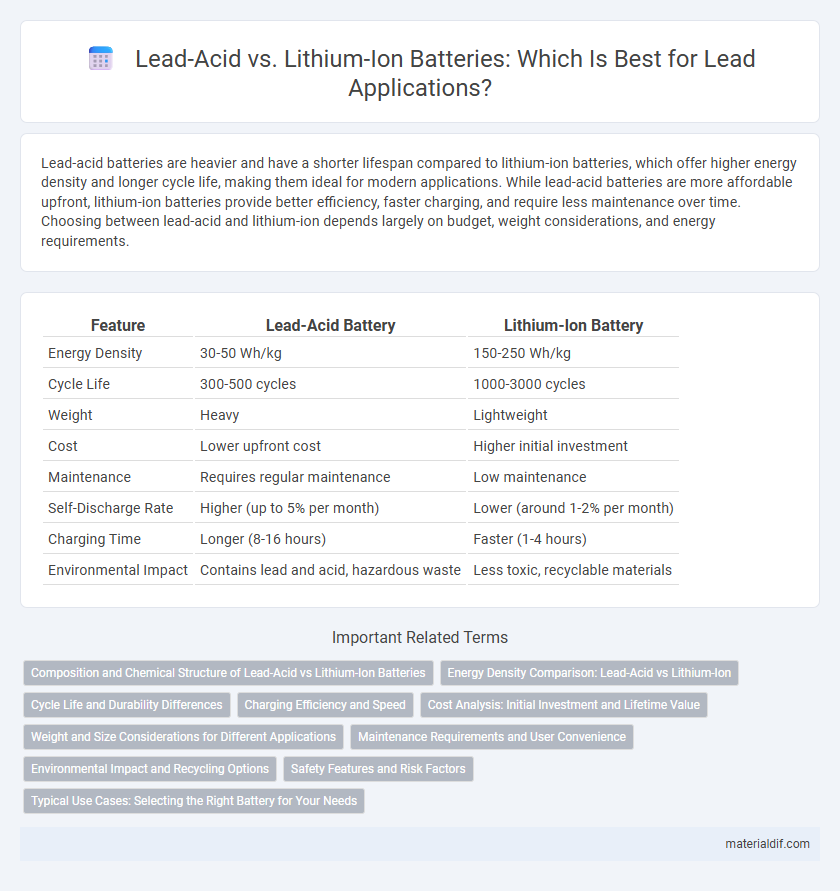

| Feature | Lead-Acid Battery | Lithium-Ion Battery |

|---|---|---|

| Energy Density | 30-50 Wh/kg | 150-250 Wh/kg |

| Cycle Life | 300-500 cycles | 1000-3000 cycles |

| Weight | Heavy | Lightweight |

| Cost | Lower upfront cost | Higher initial investment |

| Maintenance | Requires regular maintenance | Low maintenance |

| Self-Discharge Rate | Higher (up to 5% per month) | Lower (around 1-2% per month) |

| Charging Time | Longer (8-16 hours) | Faster (1-4 hours) |

| Environmental Impact | Contains lead and acid, hazardous waste | Less toxic, recyclable materials |

Composition and Chemical Structure of Lead-Acid vs Lithium-Ion Batteries

Lead-acid batteries consist of lead dioxide (PbO2) cathodes, sponge lead (Pb) anodes, and sulfuric acid (H2SO4) electrolyte, facilitating electrochemical reactions through lead sulfate formation during discharge. Lithium-ion batteries utilize lithium metal oxides (such as LiCoO2) as cathodes and graphite anodes, with organic electrolytes containing lithium salts enabling lithium-ion intercalation. The distinct chemical structures influence energy density, cycle life, and weight, with lithium-ion's layered structure offering higher efficiency compared to the denser lead-sulfate matrix.

Energy Density Comparison: Lead-Acid vs Lithium-Ion

Lithium-ion batteries exhibit significantly higher energy density compared to lead-acid batteries, typically ranging from 150 to 250 Wh/kg, whereas lead-acid batteries average around 30 to 50 Wh/kg. This higher energy density in lithium-ion batteries allows for longer runtime and reduced weight, making them more suitable for portable and high-performance applications. Lead-acid batteries, although heavier and bulkier, remain cost-effective and reliable for stationary energy storage where weight and space are less critical.

Cycle Life and Durability Differences

Lead-acid batteries typically offer 300 to 500 cycles before capacity significantly declines, making them less durable compared to lithium-ion counterparts which can deliver 2,000 to 5,000 cycles. The extended cycle life of lithium-ion batteries results from superior chemical stability and lower degradation rates under normal operating conditions. Lead-acid batteries suffer from sulfation and corrosion, reducing lifespan, whereas lithium-ion technology maintains consistent capacity over more extended use, enhancing overall durability.

Charging Efficiency and Speed

Lithium-ion batteries exhibit significantly higher charging efficiency, typically around 90-95%, compared to lead-acid batteries, which average 70-85%. The faster charging speed of lithium-ion cells allows them to reach full charge in 1-3 hours, whereas lead-acid batteries often require 8-12 hours. This efficiency and speed advantage make lithium-ion batteries ideal for applications demanding rapid turnaround and reduced energy loss.

Cost Analysis: Initial Investment and Lifetime Value

Lead-acid batteries have a lower initial investment cost, typically ranging between $100 to $200 per kWh, but their shorter lifespan of 3-5 years results in higher replacement frequency and cumulative expenses. Lithium-ion batteries, although priced higher upfront at approximately $400 to $600 per kWh, offer a longer lifespan of 10-15 years and superior energy density, generating better lifetime value and reduced total cost of ownership. The cost per cycle for lithium-ion is significantly lower, making it a more economical choice for long-term energy storage despite the steeper initial investment.

Weight and Size Considerations for Different Applications

Lead-acid batteries weigh significantly more and occupy larger volumes compared to lithium-ion batteries, making them less suitable for weight-sensitive applications such as electric vehicles and portable electronics. Lithium-ion batteries offer a higher energy density, enabling more compact and lightweight designs that enhance overall efficiency and usability. The reduced weight and size of lithium-ion cells improve performance in aerospace, automotive, and renewable energy storage systems where space and mass constraints are critical.

Maintenance Requirements and User Convenience

Lead-acid batteries require regular maintenance such as checking electrolyte levels, cleaning terminals, and equalizing charges to prevent sulfation and extend lifespan, making them less user-friendly. Lithium-ion batteries offer low maintenance with sealed designs that eliminate the need for electrolyte checks and typically include battery management systems for optimal performance and safety. The convenience of lithium-ion's lightweight structure and longer cycle life makes them more suitable for modern applications where ease of use and minimal upkeep are priorities.

Environmental Impact and Recycling Options

Lead-acid batteries contain toxic lead and sulfuric acid, posing significant environmental hazards during disposal and requiring specialized recycling processes to prevent soil and water contamination. Lithium-ion batteries, while having a higher energy density and longer lifespan, involve extraction of critical minerals such as lithium, cobalt, and nickel, raising concerns about mining impacts and resource depletion. Recycling technologies for lithium-ion are advancing but remain less established than lead-acid recycling, highlighting the need for improved circular economy solutions in battery waste management.

Safety Features and Risk Factors

Lead-acid batteries contain sulfuric acid and emit hydrogen gas, posing risks of acid leaks and explosions if damaged or improperly maintained, while Lithium-ion batteries feature advanced safety mechanisms such as thermal management systems and overcharge protection to reduce fire hazards. Lead-acid cells are more prone to sulfation and corrosion, which can cause early failure and safety hazards, whereas lithium-ion technology uses stable electrolytes and robust casings to mitigate short circuits and thermal runaway. Understanding the chemical stability and ventilation requirements is critical when comparing safety and risk factors between lead-acid and lithium-ion battery systems.

Typical Use Cases: Selecting the Right Battery for Your Needs

Lead-acid batteries are commonly used in automotive starters, uninterruptible power supplies (UPS), and backup power systems due to their cost-effectiveness and reliability in high-current applications. Lithium-ion batteries excel in portable electronics, electric vehicles, and renewable energy storage because of their higher energy density, longer cycle life, and lighter weight. Choosing between lead-acid and lithium-ion depends on factors like budget, weight constraints, and required battery lifespan for your specific use case.

Lead-acid vs Lithium-ion Infographic

materialdif.com

materialdif.com