Lead glass contains a significant amount of lead oxide, which increases its density, brilliance, and refractive index compared to soda-lime glass. Soda-lime glass, composed primarily of silica, sodium oxide, and calcium oxide, is more affordable and commonly used for everyday items like windows and bottles due to its durability and ease of manufacturing. The higher lead content in lead glass enhances its clarity and weight, making it ideal for decorative objects and optical applications, while soda-lime glass remains the practical choice for mass production.

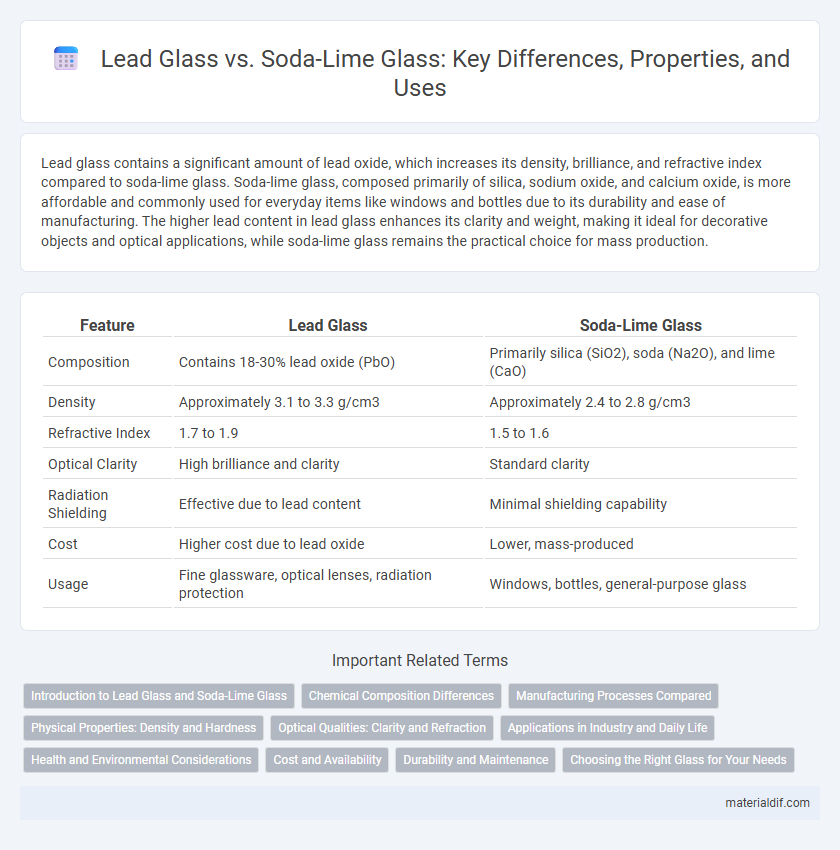

Table of Comparison

| Feature | Lead Glass | Soda-Lime Glass |

|---|---|---|

| Composition | Contains 18-30% lead oxide (PbO) | Primarily silica (SiO2), soda (Na2O), and lime (CaO) |

| Density | Approximately 3.1 to 3.3 g/cm3 | Approximately 2.4 to 2.8 g/cm3 |

| Refractive Index | 1.7 to 1.9 | 1.5 to 1.6 |

| Optical Clarity | High brilliance and clarity | Standard clarity |

| Radiation Shielding | Effective due to lead content | Minimal shielding capability |

| Cost | Higher cost due to lead oxide | Lower, mass-produced |

| Usage | Fine glassware, optical lenses, radiation protection | Windows, bottles, general-purpose glass |

Introduction to Lead Glass and Soda-Lime Glass

Lead glass contains lead oxide, typically between 18-40%, enhancing its refractive index and brilliance, making it ideal for decorative and optical applications. Soda-lime glass, composed mainly of silica, soda, and lime, is the most common glass type used for windows, bottles, and everyday items due to its affordability and durability. The distinct chemical compositions result in differing optical properties, density, and usage across various industries.

Chemical Composition Differences

Lead glass contains a high percentage of lead oxide (typically 18-40%), which increases its density, refractive index, and brilliance, making it ideal for decorative and optical applications. Soda-lime glass primarily consists of silica (about 70-74%), sodium oxide, and calcium oxide, providing durability and affordability for everyday uses like windows and bottles. The presence of lead oxide in lead glass significantly alters its chemical and physical properties compared to the alkali and alkaline earth metal oxides dominating soda-lime glass composition.

Manufacturing Processes Compared

Lead glass manufacturing involves adding lead oxide to the silica mixture, which lowers the melting point and increases the density, resulting in enhanced brilliance and clarity compared to soda-lime glass. Soda-lime glass production uses a blend of silica, soda ash, and lime, melted at higher temperatures without lead additives, yielding a more durable and cost-effective material suited for everyday use. The distinct melting temperatures and raw material compositions are key factors influencing their respective clarity, weight, and manufacturing efficiency.

Physical Properties: Density and Hardness

Lead glass exhibits a significantly higher density, approximately 3.1 to 4.0 g/cm3, compared to soda-lime glass, which typically has a density around 2.4 to 2.8 g/cm3. The increased density in lead glass results from its lead oxide content, enhancing its brilliance and weight. Hardness values also differ; lead glass tends to have a Mohs hardness of about 5 to 5.5, whereas soda-lime glass is harder, with a Mohs hardness near 5.5 to 6.0, making it more resistant to scratches and physical wear.

Optical Qualities: Clarity and Refraction

Lead glass exhibits superior optical qualities compared to soda-lime glass due to its higher refractive index, resulting in enhanced brilliance and clarity. The increased density of lead glass amplifies light refraction, producing remarkable sparkle and a more vibrant appearance. Soda-lime glass, with its lower refractive index, provides less clarity and brilliance, making it less suitable for applications demanding high optical performance.

Applications in Industry and Daily Life

Lead glass offers superior radiation shielding and optical clarity, making it ideal for medical imaging equipment, protective windows, and decorative art pieces. Soda-lime glass, with its affordability and durability, dominates everyday items like beverage containers, windows, and jars. Industrial applications favor lead glass in precision instruments, while soda-lime glass serves large-scale manufacturing needs due to its cost-effectiveness.

Health and Environmental Considerations

Lead glass contains lead oxide, significantly enhancing its brilliance and weight but posing health risks due to lead leaching, which can contaminate water and food sources. Soda-lime glass, the most common form of glass, is safer for everyday use as it lacks toxic elements and is more environmentally friendly since it requires less energy to produce and is easier to recycle. Proper disposal and recycling of lead glass are essential to prevent environmental contamination and reduce heavy metal exposure.

Cost and Availability

Lead glass generally costs more than soda-lime glass due to its higher lead oxide content, which enhances brilliance and density but increases production expenses. Soda-lime glass is widely available and economically manufactured, making it the most common glass type for everyday applications. The cost-effectiveness and accessibility of soda-lime glass make it preferable for bulk production, while lead glass is reserved for specialized uses where optical clarity and weight are prioritized.

Durability and Maintenance

Lead glass exhibits higher durability than soda-lime glass due to its increased density and resistance to scratching and chemical corrosion. Its enhanced durability reduces maintenance frequency, making it ideal for applications requiring long-lasting clarity and strength. In contrast, soda-lime glass is more prone to surface wear and requires more regular cleaning and replacement to maintain its appearance and function.

Choosing the Right Glass for Your Needs

Lead glass offers superior clarity and brilliance due to its high refractive index, making it ideal for decorative items and high-quality optical applications. Soda-lime glass is more affordable, durable, and widely used in everyday containers and windows, providing practicality without the weight or expense of lead glass. Selecting the appropriate glass depends on balancing clarity and aesthetic appeal against cost and application durability requirements.

Lead Glass vs Soda-Lime Glass Infographic

materialdif.com

materialdif.com