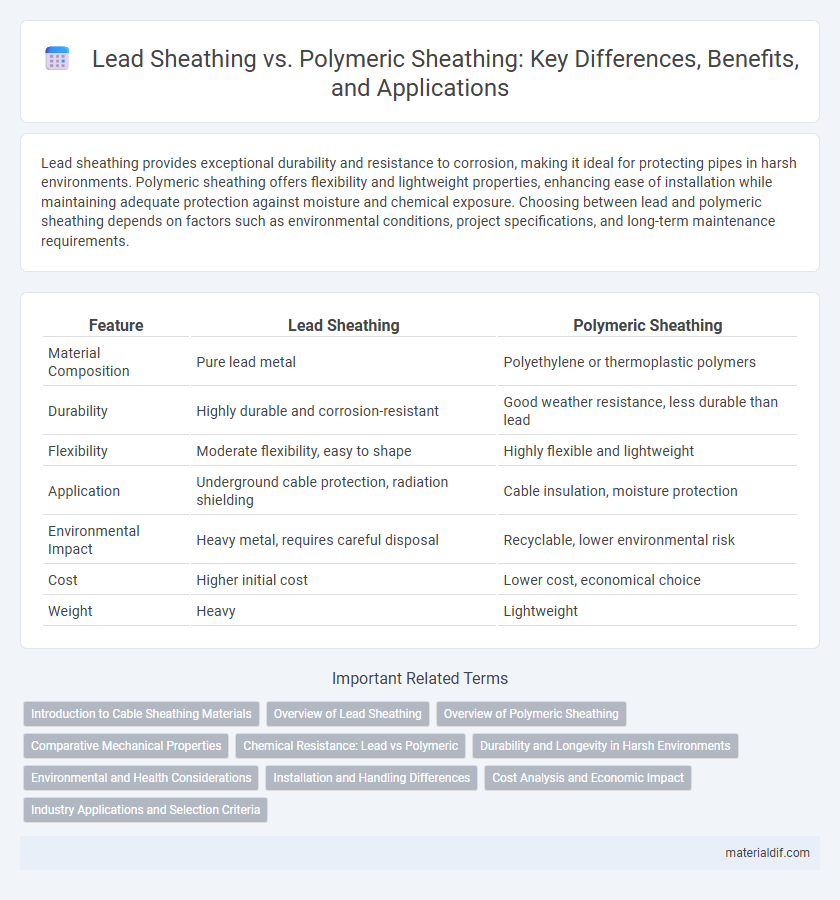

Lead sheathing provides exceptional durability and resistance to corrosion, making it ideal for protecting pipes in harsh environments. Polymeric sheathing offers flexibility and lightweight properties, enhancing ease of installation while maintaining adequate protection against moisture and chemical exposure. Choosing between lead and polymeric sheathing depends on factors such as environmental conditions, project specifications, and long-term maintenance requirements.

Table of Comparison

| Feature | Lead Sheathing | Polymeric Sheathing |

|---|---|---|

| Material Composition | Pure lead metal | Polyethylene or thermoplastic polymers |

| Durability | Highly durable and corrosion-resistant | Good weather resistance, less durable than lead |

| Flexibility | Moderate flexibility, easy to shape | Highly flexible and lightweight |

| Application | Underground cable protection, radiation shielding | Cable insulation, moisture protection |

| Environmental Impact | Heavy metal, requires careful disposal | Recyclable, lower environmental risk |

| Cost | Higher initial cost | Lower cost, economical choice |

| Weight | Heavy | Lightweight |

Introduction to Cable Sheathing Materials

Lead sheathing offers exceptional corrosion resistance and radiation shielding properties, making it ideal for underground and nuclear cable applications. Polymeric sheathing, composed of materials like polyethylene or PVC, provides flexibility, lightweight, and cost-effective protection against moisture and mechanical damage. Choosing between lead and polymeric sheathing depends on environmental conditions, durability requirements, and regulatory standards in cable installations.

Overview of Lead Sheathing

Lead sheathing offers superior corrosion resistance and durability, making it a preferred choice for underground and marine cable protection. Its malleability allows for easy application around complex shapes, while its dense structure provides excellent shielding against moisture and electromagnetic interference. Compared to polymeric sheathing, lead sheathing withstands extreme temperatures and mechanical stresses more effectively, ensuring long-term cable integrity in harsh environments.

Overview of Polymeric Sheathing

Polymeric sheathing offers enhanced corrosion resistance and flexibility compared to traditional lead sheathing, making it ideal for modern cable protection in harsh environments. Composed of materials like polyethylene or PVC, it provides superior insulation and environmental durability while reducing weight and ease of installation. Its versatility in various applications, including underground and underwater cables, ensures long-term performance and safety.

Comparative Mechanical Properties

Lead sheathing offers superior density and malleability, providing excellent durability and resistance to corrosion under mechanical stress. Polymeric sheathing generally delivers higher tensile strength and flexibility, which enhances impact resistance and reduces cracking in dynamic environments. Compared to polymeric options, lead sheathing exhibits better shielding against electromagnetic interference but is heavier and less resistant to UV degradation.

Chemical Resistance: Lead vs Polymeric

Lead sheathing offers exceptional chemical resistance against acids, alkalis, and solvents, making it highly durable in aggressive environments. Polymeric sheathing, while resistant to many chemicals, can degrade when exposed to strong acids or solvents over prolonged periods. The superior chemical inertness of lead makes it preferable for applications requiring long-term protection against corrosive substances.

Durability and Longevity in Harsh Environments

Lead sheathing offers superior durability and longevity in harsh environments due to its natural corrosion resistance and malleability, making it highly effective against moisture, chemicals, and temperature fluctuations. Polymeric sheathing, while lightweight and cost-effective, tends to degrade faster under UV exposure, extreme temperatures, and chemical contact, resulting in a shorter service life. For applications demanding maximum protection and extended lifespan, lead sheathing remains the preferred choice despite its higher initial cost.

Environmental and Health Considerations

Lead sheathing, commonly used for its durability and corrosion resistance, poses significant environmental and health risks due to lead's toxicity and potential for contamination in soil and water. Polymeric sheathing offers a safer alternative, minimizing exposure to hazardous substances and reducing environmental impact through non-toxic, recyclable materials. Choosing polymeric sheathing aligns with growing regulatory standards aimed at protecting public health and ecosystems from lead pollution.

Installation and Handling Differences

Lead sheathing requires specialized handling due to its heaviness and malleability, allowing easy shaping but necessitating careful manual installation to avoid damage. Polymeric sheathing is lighter and more flexible, enabling quicker installation with less manual effort and reducing the risk of deformation during handling. The durability of lead resists environmental factors but demands expert handling, whereas polymeric materials offer easier transport and installation but may require additional protective measures against UV exposure and chemical degradation.

Cost Analysis and Economic Impact

Lead sheathing offers superior durability and corrosion resistance but incurs higher initial material and installation costs compared to polymeric sheathing, which is more cost-effective upfront. Polymeric sheathing presents lower manufacturing expenses and easier handling, leading to reduced labor costs, though it may require more frequent maintenance or replacement, impacting long-term economic viability. A comprehensive cost analysis must weigh the higher capital investment of lead against the potential lifecycle savings and environmental compliance costs associated with polymeric alternatives.

Industry Applications and Selection Criteria

Lead sheathing offers superior protection against moisture and chemical corrosion, making it ideal for underground and marine pipeline applications where durability is critical. Polymeric sheathing provides lightweight, cost-effective insulation suitable for electrical cables and telecommunications, emphasizing flexibility and ease of installation. Selection criteria prioritize environment exposure, mechanical stress, regulatory compliance, and budget constraints to optimize performance and longevity in specific industry sectors.

Lead sheathing vs Polymeric sheathing Infographic

materialdif.com

materialdif.com