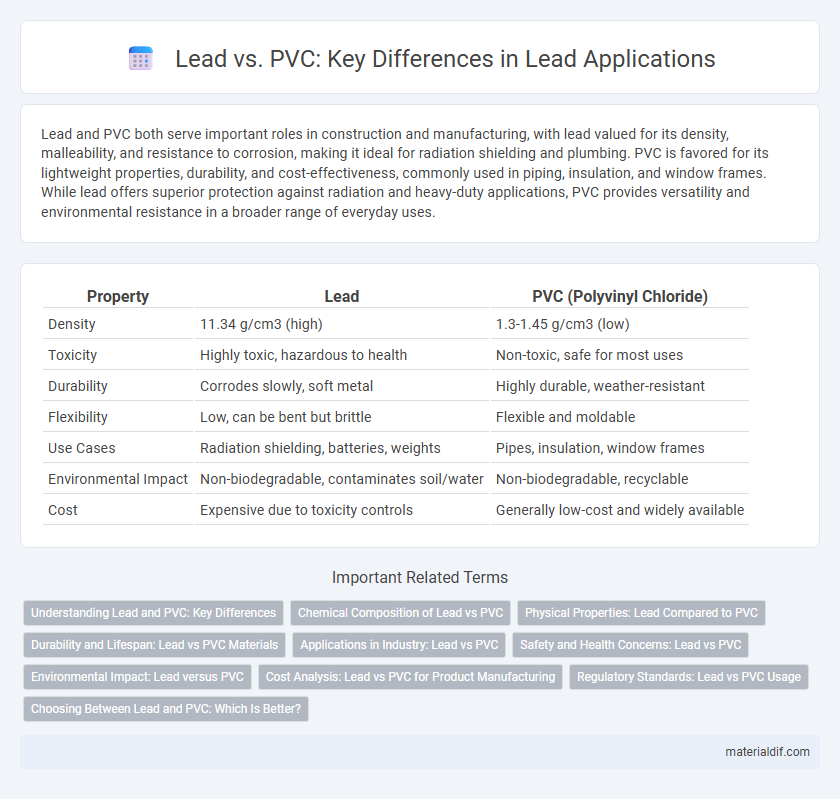

Lead and PVC both serve important roles in construction and manufacturing, with lead valued for its density, malleability, and resistance to corrosion, making it ideal for radiation shielding and plumbing. PVC is favored for its lightweight properties, durability, and cost-effectiveness, commonly used in piping, insulation, and window frames. While lead offers superior protection against radiation and heavy-duty applications, PVC provides versatility and environmental resistance in a broader range of everyday uses.

Table of Comparison

| Property | Lead | PVC (Polyvinyl Chloride) |

|---|---|---|

| Density | 11.34 g/cm3 (high) | 1.3-1.45 g/cm3 (low) |

| Toxicity | Highly toxic, hazardous to health | Non-toxic, safe for most uses |

| Durability | Corrodes slowly, soft metal | Highly durable, weather-resistant |

| Flexibility | Low, can be bent but brittle | Flexible and moldable |

| Use Cases | Radiation shielding, batteries, weights | Pipes, insulation, window frames |

| Environmental Impact | Non-biodegradable, contaminates soil/water | Non-biodegradable, recyclable |

| Cost | Expensive due to toxicity controls | Generally low-cost and widely available |

Understanding Lead and PVC: Key Differences

Lead is a heavy, malleable metal often used in construction and plumbing due to its corrosion resistance, while PVC (polyvinyl chloride) is a durable plastic commonly used for piping and insulation. Lead poses health risks such as toxicity and environmental contamination, whereas PVC offers safer handling and greater flexibility in installation. Understanding these key differences in material properties, health implications, and application suitability is crucial for making informed choices in building projects.

Chemical Composition of Lead vs PVC

Lead is a heavy metal with the chemical symbol Pb and atomic number 82, composed primarily of pure elemental lead with trace impurities. PVC (polyvinyl chloride) is a synthetic polymer composed of carbon, hydrogen, and chlorine atoms arranged in repeating vinyl chloride monomers (C2H3Cl)n. The chemical composition of lead is metallic and elemental, whereas PVC is a complex organic compound combining carbon chains with chlorine atoms, resulting in distinct physical and chemical properties.

Physical Properties: Lead Compared to PVC

Lead exhibits a high density of 11.34 g/cm3, making it significantly heavier than PVC, which has a density around 1.38 g/cm3. Its malleability and softness allow easy shaping, contrasting with PVC's rigidity and resistance to deformation. Lead also offers superior thermal conductivity of 35.3 W/m*K compared to PVC's low thermal conductivity of approximately 0.19 W/m*K, influencing their applications in heat management.

Durability and Lifespan: Lead vs PVC Materials

Lead exhibits exceptional durability and a lifespan often exceeding 100 years due to its resistance to corrosion and environmental factors, making it suitable for long-term applications. PVC, while more affordable and lightweight, generally offers a shorter lifespan of around 50 years and can degrade under prolonged UV exposure and extreme temperatures. Choosing between lead and PVC depends on the required durability and longevity for specific construction or plumbing projects.

Applications in Industry: Lead vs PVC

Lead is widely used in industrial applications requiring radiation shielding and corrosion resistance, such as in nuclear facilities, batteries, and chemical plants. PVC is favored for electrical insulation, plumbing, and construction due to its durability, flexibility, and resistance to chemicals. While lead offers superior density and protection, PVC's lightweight and non-toxic properties make it ideal for safer, eco-friendly industrial uses.

Safety and Health Concerns: Lead vs PVC

Lead poses significant safety and health concerns due to its toxic nature, leading to neurotoxicity, especially in children, and potential long-term exposure risks such as kidney damage and developmental delays. PVC, while generally safer, contains additives like phthalates and chlorine that can release harmful chemicals during manufacturing and disposal, raising concerns about respiratory issues and environmental pollution. Both materials require careful handling and regulation to minimize health hazards and environmental impact.

Environmental Impact: Lead versus PVC

Lead poses significant environmental hazards due to its toxicity and persistence, causing soil and water contamination that adversely affects ecosystems and human health. PVC, while less toxic during use, generates harmful dioxins and releases toxic chemicals during manufacturing and incineration, contributing to air and water pollution. Choosing materials with lower life cycle environmental footprints is crucial for reducing long-term ecological and health impacts.

Cost Analysis: Lead vs PVC for Product Manufacturing

Lead offers superior durability and corrosion resistance but comes with significantly higher raw material and processing costs compared to PVC. PVC provides a cost-effective alternative with lower material expenses and easier manufacturing processes, making it ideal for large-scale production where budget constraints are critical. Evaluating the total cost of ownership, including maintenance and environmental disposal, positions PVC as the more economically viable option for most product manufacturing applications.

Regulatory Standards: Lead vs PVC Usage

Regulatory standards for lead and PVC usage vary significantly due to their environmental and health impacts, with lead strictly limited or banned in many countries because of its toxicity and potential to cause neurological damage. PVC, while generally regarded as safer, is regulated for its chlorine content and the use of harmful additives like phthalates and heavy metals to mitigate environmental pollution during production and disposal. Compliance with international standards such as RoHS, REACH, and EPA guidelines dictates the permissible applications of lead and PVC, prioritizing safer alternatives and rigorous monitoring.

Choosing Between Lead and PVC: Which Is Better?

Choosing between lead and PVC depends on factors like durability, safety, and environmental impact. Lead pipes offer excellent corrosion resistance but pose health risks due to toxicity and heavy metal contamination. PVC provides a safer, cost-effective alternative with high chemical resistance and ease of installation, making it the preferred choice for most modern plumbing systems.

Lead vs PVC Infographic

materialdif.com

materialdif.com