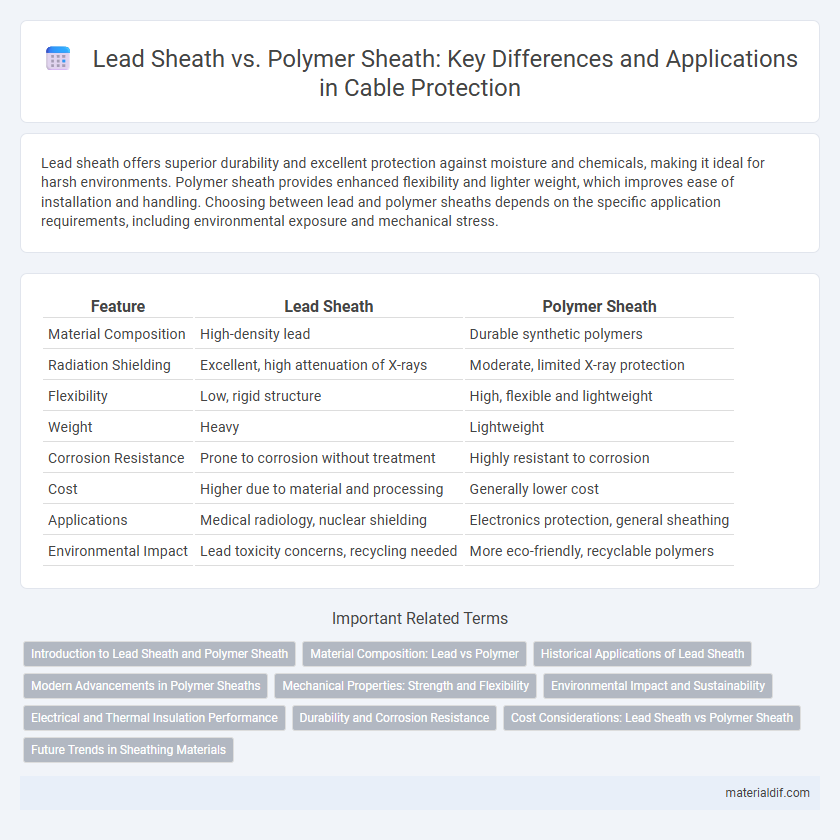

Lead sheath offers superior durability and excellent protection against moisture and chemicals, making it ideal for harsh environments. Polymer sheath provides enhanced flexibility and lighter weight, which improves ease of installation and handling. Choosing between lead and polymer sheaths depends on the specific application requirements, including environmental exposure and mechanical stress.

Table of Comparison

| Feature | Lead Sheath | Polymer Sheath |

|---|---|---|

| Material Composition | High-density lead | Durable synthetic polymers |

| Radiation Shielding | Excellent, high attenuation of X-rays | Moderate, limited X-ray protection |

| Flexibility | Low, rigid structure | High, flexible and lightweight |

| Weight | Heavy | Lightweight |

| Corrosion Resistance | Prone to corrosion without treatment | Highly resistant to corrosion |

| Cost | Higher due to material and processing | Generally lower cost |

| Applications | Medical radiology, nuclear shielding | Electronics protection, general sheathing |

| Environmental Impact | Lead toxicity concerns, recycling needed | More eco-friendly, recyclable polymers |

Introduction to Lead Sheath and Polymer Sheath

Lead sheath provides robust protection against moisture and corrosion for underground cables, often used in power distribution due to its high durability and impermeability. Polymer sheath, made from materials like polyethylene or PVC, offers flexibility, resistance to chemicals, and better environmental sustainability, making it suitable for varied applications including telecommunications and power cables. Choosing between lead sheath and polymer sheath depends on factors like environmental conditions, mechanical stress, and required longevity, with lead excelling in harsh, corrosive environments and polymer favored for lighter, more flexible needs.

Material Composition: Lead vs Polymer

Lead sheath offers superior radiation shielding and corrosion resistance due to its dense, malleable metal composition, making it ideal for high-risk environments. Polymer sheaths, composed of materials like polyethylene or PVC, provide lightweight, flexible insulation with enhanced chemical resistance but lower protection against radiation and mechanical damage. The choice between lead and polymer sheaths depends on balancing durability, environmental exposure, and shielding requirements.

Historical Applications of Lead Sheath

Lead sheath has been historically used in electrical cables due to its excellent corrosion resistance and flexibility in harsh environments, ensuring reliable protection for underground and submarine cables. The material's impermeability to moisture made it a preferred choice for telecommunication and power transmission systems throughout the 20th century. Although polymer sheaths have largely replaced lead due to environmental and health concerns, lead sheath remains significant in legacy infrastructure and high-demand industrial applications where durability is critical.

Modern Advancements in Polymer Sheaths

Modern advancements in polymer sheaths have significantly enhanced their durability, flexibility, and resistance to environmental factors compared to traditional lead sheaths. Innovations in polymer compositions, such as cross-linked polyethylene and fluoropolymer blends, offer improved insulation and protection against moisture, chemicals, and UV exposure. These developments have positioned polymer sheaths as a sustainable and efficient alternative in cable protection applications across industrial and telecommunications sectors.

Mechanical Properties: Strength and Flexibility

Lead sheath provides superior mechanical strength and excellent resistance to impact and compression, making it ideal for harsh environments. Polymer sheath, while generally less robust, offers greater flexibility and resistance to abrasion and chemicals, enhancing durability in dynamic applications. The choice depends on the required balance between strength and flexibility for specific operational conditions.

Environmental Impact and Sustainability

Lead sheath offers excellent durability and corrosion resistance, but poses significant environmental risks due to lead's toxicity and challenges in recycling. Polymer sheath alternatives, such as polyethylene or PVC, provide improved environmental sustainability through easier recyclability and reduced pollutant emissions during production and disposal. Choosing polymer sheaths supports regulatory compliance and lowers ecological footprints in cable insulation applications.

Electrical and Thermal Insulation Performance

Lead sheath provides superior electrical shielding and excellent thermal insulation due to its high density and ductility, effectively protecting cables from moisture and electromagnetic interference. Polymer sheath offers enhanced flexibility, corrosion resistance, and lightweight properties, but generally has lower thermal conductivity and electrical shielding compared to lead. In applications requiring robust electrical insulation and high thermal stability, lead sheath remains the preferred choice despite the heavier weight and environmental concerns.

Durability and Corrosion Resistance

Lead sheath offers superior corrosion resistance in harsh environments, especially against moisture and chemical exposure, making it highly durable for underground and underwater cable protection. Polymer sheath provides enhanced flexibility and resistance to abrasion but may degrade faster under prolonged UV exposure and harsh chemical conditions, impacting long-term durability. Selecting between lead and polymer sheaths depends on the specific environmental factors and the required lifespan of the cable installation.

Cost Considerations: Lead Sheath vs Polymer Sheath

Lead sheaths typically incur higher initial costs due to the expense of raw lead material and specialized installation requirements, making them less economical for large-scale projects. Polymer sheaths offer a more cost-effective solution with lower material and installation expenses, while also reducing maintenance costs over time due to their lighter weight and corrosion resistance. Long-term cost considerations favor polymer sheaths in applications prioritizing budget efficiency and durability.

Future Trends in Sheathing Materials

Future trends in lead sheathing materials emphasize the shift towards polymer sheaths due to their superior corrosion resistance, flexibility, and environmental safety. Advanced polymer composites integrated with nanomaterials enhance mechanical strength and thermal stability, making them ideal for modern cable insulation and protection. Innovations in biodegradable and recyclable polymers highlight sustainability as a key driver in the evolution of sheathing technology.

Lead sheath vs Polymer sheath Infographic

materialdif.com

materialdif.com