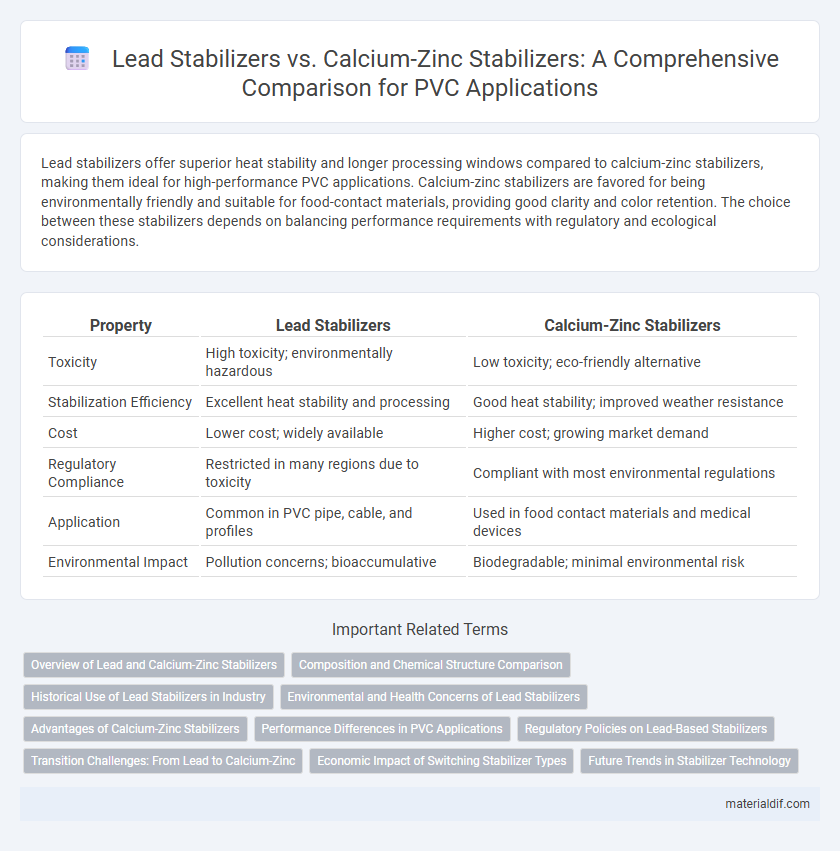

Lead stabilizers offer superior heat stability and longer processing windows compared to calcium-zinc stabilizers, making them ideal for high-performance PVC applications. Calcium-zinc stabilizers are favored for being environmentally friendly and suitable for food-contact materials, providing good clarity and color retention. The choice between these stabilizers depends on balancing performance requirements with regulatory and ecological considerations.

Table of Comparison

| Property | Lead Stabilizers | Calcium-Zinc Stabilizers |

|---|---|---|

| Toxicity | High toxicity; environmentally hazardous | Low toxicity; eco-friendly alternative |

| Stabilization Efficiency | Excellent heat stability and processing | Good heat stability; improved weather resistance |

| Cost | Lower cost; widely available | Higher cost; growing market demand |

| Regulatory Compliance | Restricted in many regions due to toxicity | Compliant with most environmental regulations |

| Application | Common in PVC pipe, cable, and profiles | Used in food contact materials and medical devices |

| Environmental Impact | Pollution concerns; bioaccumulative | Biodegradable; minimal environmental risk |

Overview of Lead and Calcium-Zinc Stabilizers

Lead stabilizers, traditionally used in PVC processing, offer excellent heat stability and cost-effectiveness, making them ideal for rigid applications such as pipes and window profiles. Calcium-zinc stabilizers serve as a non-toxic alternative, providing superior environmental safety and compatibility with flexible and clear PVC products. Both stabilizer types influence thermal degradation resistance and color retention, but calcium-zinc stabilizers excel in regulatory compliance for food and medical-grade materials.

Composition and Chemical Structure Comparison

Lead stabilizers primarily consist of basic lead salts such as lead carbonate and lead sulfate, featuring a relatively simple inorganic structure that provides effective heat stabilization in PVC. Calcium-zinc stabilizers are composed of calcium stearate and zinc stearate, exhibiting a more complex organometallic structure that enhances both thermal stability and environmental safety. The chemical interaction of lead stabilizers involves substitution of labile chlorine atoms in PVC chains, whereas calcium-zinc stabilizers function through dual metal ion mechanisms that scavenge hydrochloric acid and reinforce polymer chains.

Historical Use of Lead Stabilizers in Industry

Lead stabilizers dominated the PVC industry for much of the 20th century due to their excellent heat stability and cost-effectiveness. Their widespread use in construction, automotive, and electrical applications was driven by superior performance in maintaining polymer properties during processing. Environmental and health concerns eventually prompted a shift towards non-toxic alternatives like calcium-zinc stabilizers, which gained traction for safer, eco-friendly solutions.

Environmental and Health Concerns of Lead Stabilizers

Lead stabilizers, widely used in PVC production, pose significant environmental and health risks due to lead's toxicity and potential for bioaccumulation, leading to neurological damage and contamination of soil and water. Calcium-zinc stabilizers offer a safer alternative by eliminating heavy metal exposure while providing effective heat stability and preserving material quality. Regulatory agencies increasingly restrict lead stabilizers, driving industry adoption of calcium-zinc formulations for compliance and sustainability goals.

Advantages of Calcium-Zinc Stabilizers

Calcium-zinc stabilizers offer superior heat stability and environmental benefits compared to traditional lead stabilizers, making them ideal for PVC processing in food packaging and medical applications. These stabilizers provide excellent resistance to discoloration and enhance the longevity of PVC products without the toxicity associated with lead-based compounds. Their non-toxic nature and compliance with regulatory standards contribute to safer end products and reduced environmental impact.

Performance Differences in PVC Applications

Lead stabilizers provide exceptional heat stability and cost-effectiveness in rigid PVC applications, ensuring long processing windows and enhanced durability. Calcium-zinc stabilizers offer superior environmental compatibility and improved clarity in flexible PVC products, though they may require higher concentrations to achieve comparable thermal stability. Performance differences include lead stabilizers' stronger resistance to discoloration and degradation under prolonged heat exposure, while calcium-zinc stabilizers excel in maintaining non-toxic, eco-friendly profiles suitable for food contact and medical uses.

Regulatory Policies on Lead-Based Stabilizers

Regulatory policies on lead-based stabilizers have become increasingly stringent due to the toxicological risks associated with lead exposure, prompting many regions to enforce bans or strict limits on lead content in PVC formulations. Calcium-zinc stabilizers are favored in regulatory-compliant applications as they provide effective heat stabilization without the environmental and health hazards posed by lead compounds. Compliance with REACH in Europe and TSCA in the United States drives the industry shift toward non-lead stabilizers, ensuring safer production and end-use of PVC products.

Transition Challenges: From Lead to Calcium-Zinc

Transitioning from lead stabilizers to calcium-zinc stabilizers involves addressing differences in thermal stability, processing temperatures, and compatibility with PVC formulations. Calcium-zinc stabilizers offer eco-friendly benefits and improved heat resistance but require adjustments in processing parameters to ensure product performance. Manufacturers must optimize curing cycles and mechanical properties to achieve seamless integration and maintain material quality during this transition.

Economic Impact of Switching Stabilizer Types

Switching from lead stabilizers to calcium-zinc stabilizers significantly impacts production costs and long-term economic sustainability in the PVC industry. Lead stabilizers offer lower initial expenses but pose high environmental and health-related liabilities, increasing potential regulatory penalties and disposal costs. Calcium-zinc stabilizers, although initially more expensive, reduce long-term liabilities and foster compliance with stringent environmental regulations, potentially enhancing market access and profitability.

Future Trends in Stabilizer Technology

Lead stabilizers have been widely used for their effective heat and UV resistance in PVC applications, but emerging regulations and health concerns drive a shift towards calcium-zinc stabilizers as safer, eco-friendly alternatives. Future trends in stabilizer technology emphasize enhanced thermal stability, improved weatherability, and reduced environmental impact, with calcium-zinc systems evolving to match or exceed the performance of traditional lead-based compounds. Innovations include multifunctional additives and bio-based stabilizers aiming to comply with stringent global regulations while maintaining material durability and processing efficiency.

Lead Stabilizers vs Calcium-Zinc Stabilizers Infographic

materialdif.com

materialdif.com