Lead pet toys often provide durability and weight that enhance playtime, but lead-free alternatives prioritize safety by eliminating toxic materials harmful to pets. Choosing lead-free products reduces the risk of lead poisoning, ensuring a healthier environment for animals. Both options offer unique benefits, but lead-free items are increasingly favored for long-term pet well-being.

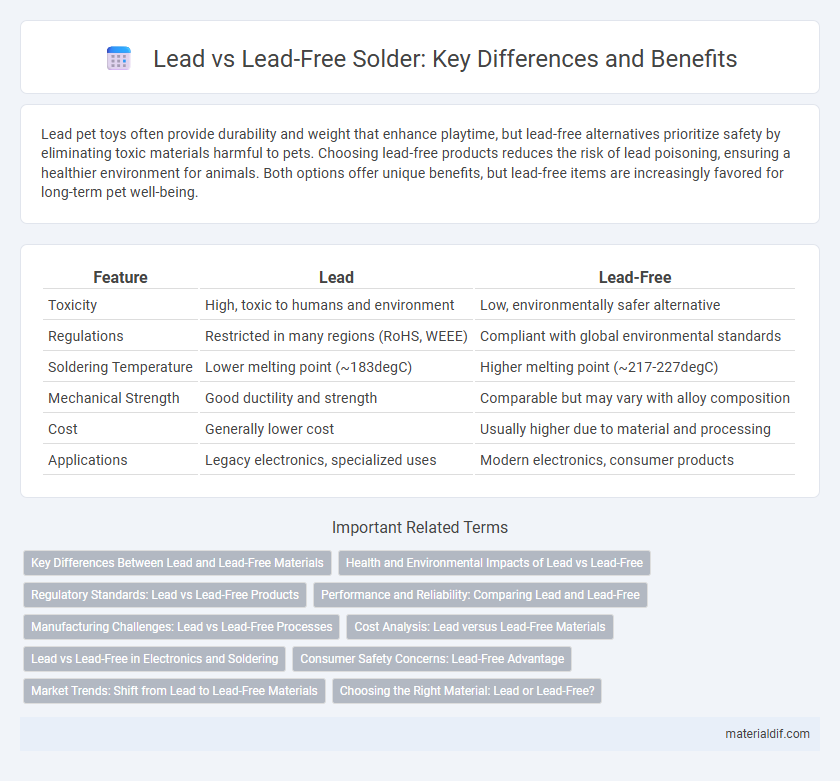

Table of Comparison

| Feature | Lead | Lead-Free |

|---|---|---|

| Toxicity | High, toxic to humans and environment | Low, environmentally safer alternative |

| Regulations | Restricted in many regions (RoHS, WEEE) | Compliant with global environmental standards |

| Soldering Temperature | Lower melting point (~183degC) | Higher melting point (~217-227degC) |

| Mechanical Strength | Good ductility and strength | Comparable but may vary with alloy composition |

| Cost | Generally lower cost | Usually higher due to material and processing |

| Applications | Legacy electronics, specialized uses | Modern electronics, consumer products |

Key Differences Between Lead and Lead-Free Materials

Lead materials exhibit high malleability and excellent thermal and electrical conductivity, which makes them ideal for traditional soldering applications. Lead-free materials, typically composed of tin, silver, and copper alloys, offer improved environmental safety and compliance with RoHS regulations but often require higher melting temperatures and may reduce mechanical reliability. The key differences lie in their chemical composition, melting points, and ecological impact, influencing manufacturing processes and product lifespan.

Health and Environmental Impacts of Lead vs Lead-Free

Lead exposure poses significant health risks, including neurological damage and developmental delays, particularly in children, while lead-free alternatives drastically reduce these hazards by eliminating toxic lead content. Environmentally, lead contaminates soil and water, causing long-lasting ecological damage, whereas lead-free materials minimize pollution and promote safer recycling processes. Transitioning to lead-free technologies supports sustainable development and decreases public health burdens associated with lead poisoning.

Regulatory Standards: Lead vs Lead-Free Products

Regulatory standards strictly limit lead content in consumer products to prevent toxicity and environmental harm, with lead-free certifications increasingly mandated across industries such as electronics and plumbing. Lead products often fail to meet RoHS (Restriction of Hazardous Substances) and CPSIA (Consumer Product Safety Improvement Act) directives, prompting manufacturers to adopt lead-free alternatives. Compliance with these regulations ensures safer products, reduces health risks, and supports sustainable manufacturing practices worldwide.

Performance and Reliability: Comparing Lead and Lead-Free

Lead-based solders offer superior thermal fatigue resistance and lower melting points, enhancing long-term joint reliability in electronic assemblies. Lead-free alternatives, primarily composed of tin, silver, and copper, typically exhibit higher melting temperatures and reduced ductility, which can increase mechanical stress and potential failure under thermal cycling. Performance metrics indicate that while lead-free solders meet environmental regulations, lead-based solders maintain better conductivity and durability in high-reliability applications.

Manufacturing Challenges: Lead vs Lead-Free Processes

Lead-based manufacturing processes benefit from lower melting points, enabling easier soldering and reduced thermal stress on components. Lead-free processes require higher temperatures, often causing increased risk of component warping and equipment wear, creating challenges in maintaining product reliability. Transitioning to lead-free also demands stricter process controls and specialized flux formulations to ensure proper joint formation.

Cost Analysis: Lead versus Lead-Free Materials

Lead materials typically offer lower upfront costs compared to lead-free alternatives due to extensive manufacturing infrastructure and supply chain optimization. Lead-free materials demand higher initial investment driven by stricter compliance, specialized processing, and raw material expenses. Long-term cost analysis must consider potential regulatory penalties, environmental disposal fees, and lifecycle sustainability, where lead-free solutions can mitigate financial risks despite higher initial pricing.

Lead vs Lead-Free in Electronics and Soldering

Lead in electronics and soldering offers superior conductivity and melting point advantages, ensuring reliable electrical connections and durability in circuit assemblies. Lead-free alternatives, driven by environmental regulations such as RoHS, rely on alloys like tin-silver-copper, which demand higher reflow temperatures and may present challenges in joint reliability and wettability. Selecting between lead and lead-free solder requires balancing performance requirements with environmental compliance and health considerations in electronic manufacturing.

Consumer Safety Concerns: Lead-Free Advantage

Lead-free products significantly reduce the risk of lead poisoning, a serious health hazard linked to cognitive impairments and developmental delays in children. Consumer safety regulations increasingly mandate lead-free materials in toys, cosmetics, and cookware to prevent exposure to toxic lead. Choosing lead-free options ensures compliance with safety standards and protects consumers from long-term health consequences.

Market Trends: Shift from Lead to Lead-Free Materials

The global electronics industry is experiencing a significant shift from lead-based solders to lead-free alternatives driven by environmental regulations such as RoHS and consumer demand for sustainable products. Market trends indicate a robust increase in the adoption of lead-free materials like SAC (Tin-Silver-Copper) alloys due to their improved reliability and compliance benefits. Forecasts predict the lead-free solder market will expand annually by over 8%, underscoring the accelerating transition away from traditional lead usage.

Choosing the Right Material: Lead or Lead-Free?

Choosing between lead and lead-free materials hinges on application requirements and environmental considerations. Lead offers superior malleability and corrosion resistance, making it ideal for certain industrial uses, while lead-free alternatives prioritize health and ecological safety by eliminating toxic elements. Evaluating regulatory compliance, durability, and potential health risks guides informed decisions for selecting the right material.

Lead vs Lead-Free Infographic

materialdif.com

materialdif.com