Lead ballast offers higher density and superior stability compared to iron ballast, making it ideal for applications requiring compact weight distribution. Iron ballast, while more cost-effective, is heavier and less efficient, potentially increasing overall weight without proportionate stability benefits. Choosing lead ballast enhances performance by minimizing size and maximizing balance in marine and automotive settings.

Table of Comparison

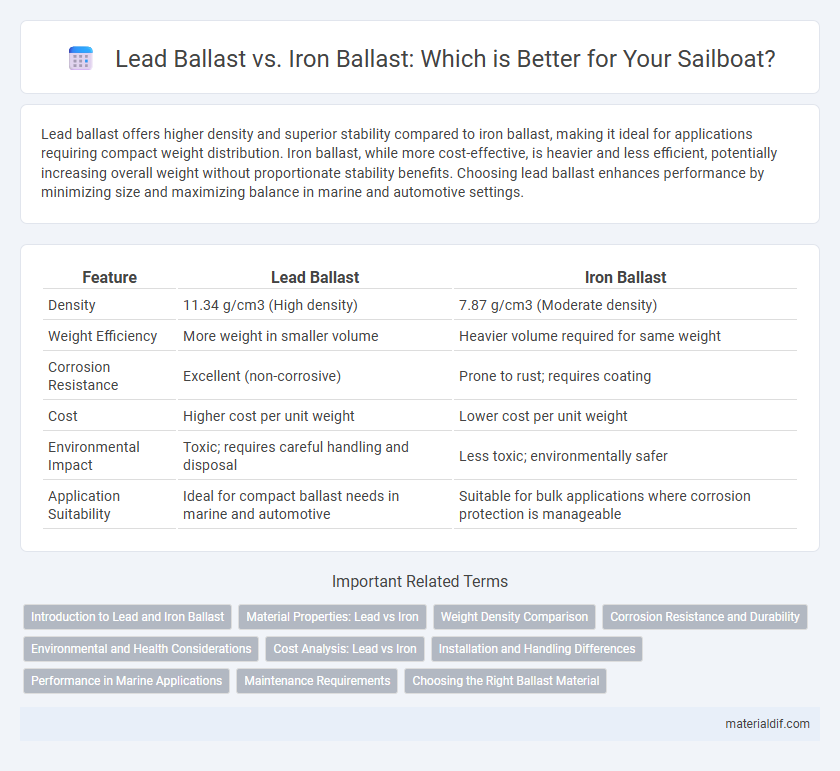

| Feature | Lead Ballast | Iron Ballast |

|---|---|---|

| Density | 11.34 g/cm3 (High density) | 7.87 g/cm3 (Moderate density) |

| Weight Efficiency | More weight in smaller volume | Heavier volume required for same weight |

| Corrosion Resistance | Excellent (non-corrosive) | Prone to rust; requires coating |

| Cost | Higher cost per unit weight | Lower cost per unit weight |

| Environmental Impact | Toxic; requires careful handling and disposal | Less toxic; environmentally safer |

| Application Suitability | Ideal for compact ballast needs in marine and automotive | Suitable for bulk applications where corrosion protection is manageable |

Introduction to Lead and Iron Ballast

Lead ballast, commonly used in marine and automotive applications, offers high density and excellent corrosion resistance, providing optimal weight distribution and stability. Iron ballast, though less dense than lead, is a cost-effective alternative with good strength, often utilized in construction and industrial settings where weight management and budget constraints are priorities. Understanding the material properties and environmental impact of lead and iron ballast is essential for selecting the appropriate ballast type for specific engineering and safety requirements.

Material Properties: Lead vs Iron

Lead ballast offers higher density, allowing more weight to be concentrated in a smaller volume compared to iron ballast, which is less dense and bulkier. Lead's superior malleability and corrosion resistance make it easier to shape and maintain, whereas iron ballast is prone to rust and requires protective coatings. Despite lead's toxicity concerns, its material properties provide enhanced stability and longevity in applications demanding compact, heavy ballast.

Weight Density Comparison

Lead ballast offers a significantly higher weight density compared to iron ballast, with lead typically around 11.34 g/cm3 versus iron's 7.87 g/cm3. This difference allows lead ballast to provide greater mass in a smaller volume, enhancing stability without increasing size. The higher density of lead makes it the preferred choice in applications requiring compact, heavy weight such as in marine and automotive industries.

Corrosion Resistance and Durability

Lead ballast offers superior corrosion resistance compared to iron ballast, as lead naturally forms a protective oxide layer that prevents further deterioration. Iron ballast, while strong and commonly used, is prone to rust and requires additional coatings or treatments to enhance durability in harsh environments. The enhanced corrosion resistance of lead ballast often leads to a longer service life and reduced maintenance costs in maritime and industrial applications.

Environmental and Health Considerations

Lead ballast poses significant environmental and health risks due to its toxicity and potential to contaminate soil and water, causing neurological damage and other serious health issues. Iron ballast offers a safer alternative with minimal ecological impact, being non-toxic and more easily recyclable without hazardous effects. Choosing iron over lead reduces the risk of heavy metal pollution and promotes a healthier environment.

Cost Analysis: Lead vs Iron

Lead ballast typically costs more than iron ballast due to the higher raw material price of lead and its greater density, which reduces the volume needed. Iron ballast is more economical upfront but may require more volume and maintenance due to corrosion risks. When factoring in longevity and weight efficiency, lead ballast can offer better value despite the initial cost difference.

Installation and Handling Differences

Lead ballast offers easier installation due to its higher density, allowing smaller volumes to achieve the same weight compared to iron ballast. Iron ballast, being less dense, requires larger size and more secure anchoring during handling and installation to maintain stability. Handling lead ballast demands caution because of toxicity risks, whereas iron ballast is generally safer but heavier and bulkier to maneuver.

Performance in Marine Applications

Lead ballast offers superior density and corrosion resistance compared to iron ballast, enhancing stability and performance in marine applications. Its higher specific gravity allows for more efficient weight distribution in smaller volumes, improving vessel agility and fuel efficiency. Iron ballast, while cost-effective, is prone to rust and requires additional coatings to maintain performance over time.

Maintenance Requirements

Lead ballast requires less frequent maintenance due to its resistance to corrosion and wear, ensuring long-term stability with minimal upkeep. Iron ballast, prone to rust and degradation over time, demands regular inspections and protective coatings to maintain performance and prevent structural damage. Choosing lead ballast reduces maintenance efforts and costs, enhancing durability in marine and industrial applications.

Choosing the Right Ballast Material

Lead ballast offers higher density than iron ballast, allowing for a more compact weight that maximizes stability in marine and automotive applications. Iron ballast, while less dense, is typically more cost-effective and resistant to corrosion when properly coated, making it suitable for budget-conscious projects. Selecting the right ballast material depends on balancing density requirements, budget constraints, and environmental factors such as exposure to moisture and potential for rust.

Lead ballast vs Iron ballast Infographic

materialdif.com

materialdif.com