Lead-free solder offers a safer and more environmentally friendly alternative to leaded solder by eliminating toxic lead content, which reduces health risks during manufacturing and disposal. It typically consists of a tin, silver, and copper alloy that provides strong mechanical and electrical connections, though it may require higher melting temperatures and can be less malleable than leaded solder. In contrast, leaded solder, traditionally made of tin and lead, offers lower melting points and better flow characteristics but poses significant health hazards and regulatory challenges due to lead's toxicity.

Table of Comparison

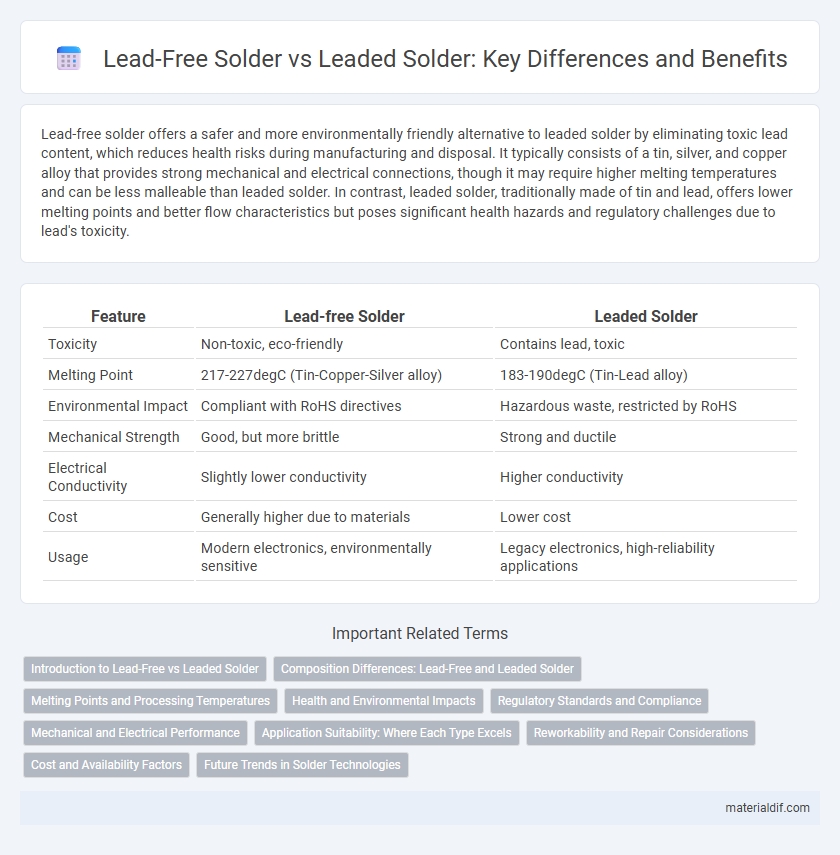

| Feature | Lead-free Solder | Leaded Solder |

|---|---|---|

| Toxicity | Non-toxic, eco-friendly | Contains lead, toxic |

| Melting Point | 217-227degC (Tin-Copper-Silver alloy) | 183-190degC (Tin-Lead alloy) |

| Environmental Impact | Compliant with RoHS directives | Hazardous waste, restricted by RoHS |

| Mechanical Strength | Good, but more brittle | Strong and ductile |

| Electrical Conductivity | Slightly lower conductivity | Higher conductivity |

| Cost | Generally higher due to materials | Lower cost |

| Usage | Modern electronics, environmentally sensitive | Legacy electronics, high-reliability applications |

Introduction to Lead-Free vs Leaded Solder

Lead-free solder, primarily composed of tin, copper, and silver, offers an environmentally safer alternative to traditional leaded solder, which contains a significant percentage of lead. The transition to lead-free solder is driven by regulations such as RoHS, aiming to reduce toxic waste and human health risks associated with lead exposure. While leaded solder provides superior electrical conductivity and ease of use, lead-free variants are continuously improved to meet the demands of modern electronics manufacturing.

Composition Differences: Lead-Free and Leaded Solder

Lead-free solder typically consists of a combination of tin, silver, and copper, often in ratios like Sn96.5/Ag3.0/Cu0.5, while leaded solder primarily contains tin and lead, commonly in the 60/40 or 63/37 Sn/Pb compositions. The absence of lead in lead-free solder reduces toxicity and environmental impact, but it generally requires higher melting temperatures compared to leaded solder, which melts around 183degC. These composition differences affect mechanical properties, wettability, and joint reliability in electronic assembly processes.

Melting Points and Processing Temperatures

Lead-free solder typically has a higher melting point, around 217-221degC, compared to leaded solder which melts at approximately 183-190degC, influencing manufacturing processes. The elevated melting temperatures of lead-free solders demand higher processing temperatures, requiring equipment adjustments and longer cooling times. These differences impact thermal profiles and energy consumption in electronics assembly, favoring leaded solder for low-temperature applications while lead-free solder meets environmental and health regulations.

Health and Environmental Impacts

Lead-free solder significantly reduces health risks by eliminating exposure to toxic lead fumes and lead contamination, which can cause neurological damage and developmental issues. Environmentally, lead-free solder minimizes soil and water pollution, preventing hazardous lead accumulation that harms ecosystems and wildlife. Transitioning to lead-free solder supports safer manufacturing practices and promotes sustainable electronic waste management.

Regulatory Standards and Compliance

Lead-free solder complies with global regulatory standards such as RoHS (Restriction of Hazardous Substances), which restricts the use of lead to reduce environmental and health risks. Leaded solder, although offering superior electrical conductivity and melting properties, is increasingly restricted by regulations in electronics manufacturing due to its toxic impact. Compliance requirements drive manufacturers to adopt lead-free alternatives, ensuring adherence to international safety and environmental guidelines.

Mechanical and Electrical Performance

Lead-free solder often exhibits higher melting points and reduced ductility compared to leaded solder, influencing mechanical reliability in thermal cycling applications. Electrical conductivity in leaded solder typically surpasses that of lead-free alternatives, ensuring marginally better signal integrity in high-frequency circuits. The choice between lead-free and leaded solder impacts joint strength and performance stability in electronic assemblies, with leaded variants providing superior mechanical resilience and lead-free options aligning with environmental regulations.

Application Suitability: Where Each Type Excels

Lead-free solder excels in electronics manufacturing with stringent environmental regulations, offering superior thermal fatigue resistance for complex circuit boards and outdoor applications. Leaded solder remains preferred in high-reliability aerospace and military sectors due to its lower melting point and ease of use, ensuring robust mechanical strength and reduced joint defects. Selection depends on application requirements, regulatory compliance, and desired long-term performance characteristics.

Reworkability and Repair Considerations

Lead-free solder typically presents challenges in reworkability due to its higher melting point and increased hardness compared to leaded solder, which can cause more thermal stress on components during repair. Leaded solder offers superior wetting properties and easier flow, facilitating more efficient rework and reducing the risk of damage to delicate parts. Repair considerations favor leaded solder in applications requiring frequent maintenance, while lead-free solder demands advanced techniques and equipment for effective rework.

Cost and Availability Factors

Lead-free solder generally costs more than leaded solder due to the use of alternative metals like tin, silver, and copper, which are pricier and subject to market fluctuations. Leaded solder remains more widely available and affordable because it has been the industry standard for decades, resulting in established manufacturing and supply chains. Cost-conscious manufacturers often face higher expenses and limited supply options when switching to lead-free solder, impacting production budgets and timelines.

Future Trends in Solder Technologies

Future trends in solder technologies emphasize the shift toward lead-free solder due to environmental regulations such as RoHS and the global push for sustainable electronics manufacturing. Innovations in lead-free solder alloys like SAC305 (tin-silver-copper) enhance mechanical strength and thermal fatigue resistance, addressing reliability challenges in high-performance applications. Emerging materials like nano-solder and low-temperature soldering solutions are poised to improve manufacturing efficiency and environmental safety in next-generation electronic devices.

Lead-free Solder vs Leaded Solder Infographic

materialdif.com

materialdif.com