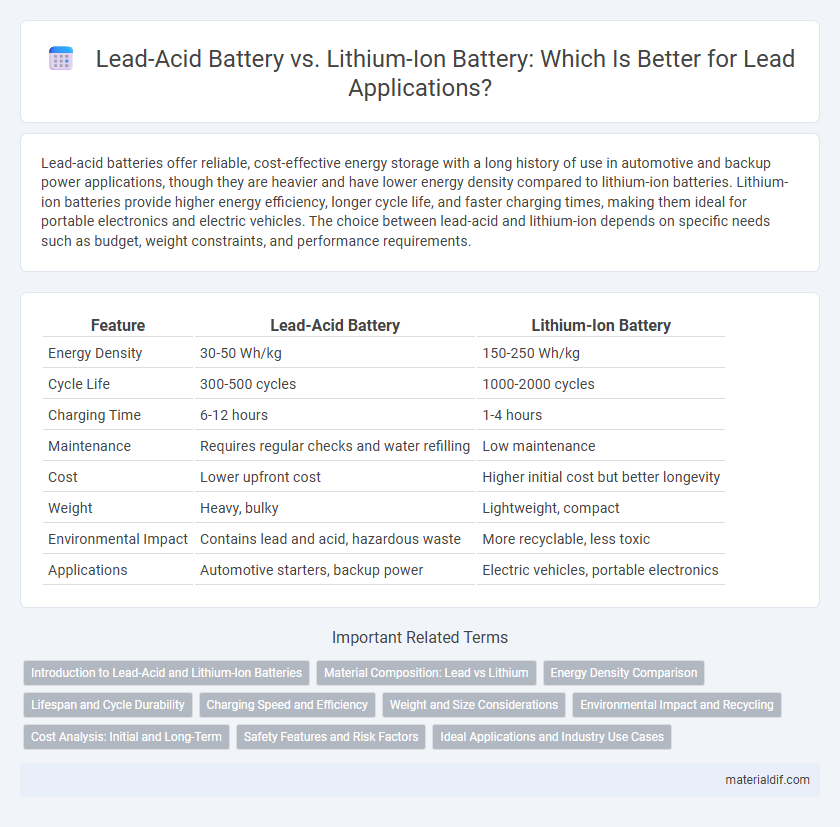

Lead-acid batteries offer reliable, cost-effective energy storage with a long history of use in automotive and backup power applications, though they are heavier and have lower energy density compared to lithium-ion batteries. Lithium-ion batteries provide higher energy efficiency, longer cycle life, and faster charging times, making them ideal for portable electronics and electric vehicles. The choice between lead-acid and lithium-ion depends on specific needs such as budget, weight constraints, and performance requirements.

Table of Comparison

| Feature | Lead-Acid Battery | Lithium-Ion Battery |

|---|---|---|

| Energy Density | 30-50 Wh/kg | 150-250 Wh/kg |

| Cycle Life | 300-500 cycles | 1000-2000 cycles |

| Charging Time | 6-12 hours | 1-4 hours |

| Maintenance | Requires regular checks and water refilling | Low maintenance |

| Cost | Lower upfront cost | Higher initial cost but better longevity |

| Weight | Heavy, bulky | Lightweight, compact |

| Environmental Impact | Contains lead and acid, hazardous waste | More recyclable, less toxic |

| Applications | Automotive starters, backup power | Electric vehicles, portable electronics |

Introduction to Lead-Acid and Lithium-Ion Batteries

Lead-acid batteries utilize lead plates and sulfuric acid electrolyte to store and release electrical energy through chemical reactions, offering reliable performance in automotive and backup power applications. Lithium-ion batteries employ lithium compounds and graphite electrodes, providing higher energy density, longer cycle life, and faster charging capabilities for portable electronics and electric vehicles. The fundamental differences in electrochemistry and materials result in distinct advantages and usage scenarios for each battery type.

Material Composition: Lead vs Lithium

Lead-acid batteries primarily use lead dioxide (PbO2) and sponge lead (Pb) as active materials, combined with sulfuric acid electrolyte, providing high recyclability and cost-effectiveness for energy storage. Lithium-ion batteries utilize lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), or other lithium metal oxides as cathode materials, paired with graphite anodes, resulting in higher energy density and lighter weight. The fundamental difference in material composition directly impacts the electrochemical properties, cycle life, and application suitability of each battery technology.

Energy Density Comparison

Lead-acid batteries typically have an energy density of 30-50 Wh/kg, which is significantly lower than lithium-ion batteries that range from 150-250 Wh/kg. This higher energy density in lithium-ion batteries enables longer runtimes and lighter weight for portable devices and electric vehicles. Consequently, lithium-ion technology is preferred in applications demanding compact storage and extended energy capacity.

Lifespan and Cycle Durability

Lead-acid batteries typically offer a lifespan of 3 to 5 years with around 500 to 1,000 charge cycles, while lithium-ion batteries can last 8 to 15 years and endure 2,000 to 5,000 charge cycles. The superior cycle durability of lithium-ion batteries is due to their advanced chemistry, enabling more consistent performance over time. This longer lifespan and higher cycle count make lithium-ion batteries more cost-effective and reliable for long-term energy storage applications.

Charging Speed and Efficiency

Lead-acid batteries typically exhibit slower charging speeds and lower energy efficiency compared to lithium-ion batteries, which can charge rapidly and maintain higher charge retention rates. Lithium-ion technology offers superior cyclical efficiency, losing less capacity over repeated charging cycles than lead-acid chemistry. This translates into quicker recharge times and more effective energy use, making lithium-ion batteries preferable for applications demanding fast turnaround and long service life.

Weight and Size Considerations

Lead-acid batteries are significantly heavier and bulkier compared to lithium-ion batteries, making lithium-ion the preferred choice for applications requiring compactness and lightweight solutions. Lithium-ion batteries offer a higher energy density, enabling smaller sizes without sacrificing capacity or performance. This weight and size efficiency enhances portability and installation flexibility in electric vehicles, renewable energy systems, and portable electronics.

Environmental Impact and Recycling

Lead-acid batteries contain toxic lead and sulfuric acid, posing significant environmental risks if not properly recycled, but their recycling rate exceeds 95%, making them highly sustainable in terms of material recovery. Lithium-ion batteries, while having a lower toxicity profile, involve complex recycling processes due to diverse chemistries and require significant energy input, resulting in challenges for large-scale material recovery and environmental impact mitigation. Innovations in recycling technologies and regulations are critical for reducing the ecological footprint of both battery types, with lead-acid systems currently benefiting from a more established circular economy infrastructure.

Cost Analysis: Initial and Long-Term

Lead-acid batteries generally have a lower initial cost compared to lithium-ion batteries, making them more accessible for budget-conscious applications. However, lithium-ion batteries offer a longer lifespan and higher energy density, resulting in lower total cost of ownership over time due to reduced maintenance and replacement expenses. The long-term financial benefits of lithium-ion technology often outweigh the upfront savings of lead-acid options in scalable energy storage solutions.

Safety Features and Risk Factors

Lead-acid batteries offer robust safety features with lower risk of thermal runaway due to their stable chemical composition but pose hazards like acid leakage and heavy metal contamination. Lithium-ion batteries provide higher energy density and longer cycle life but carry increased safety risks, including overheating, fire, and explosion caused by internal short circuits or mechanical damage. Proper management systems and protective circuitry are critical in lithium-ion batteries to mitigate these risks, while lead-acid batteries require careful handling to prevent acid spills and environmental harm.

Ideal Applications and Industry Use Cases

Lead-acid batteries remain ideal for automotive starters, uninterruptible power supplies (UPS), and renewable energy storage due to their low cost and reliable performance in high-discharge scenarios. Lithium-ion batteries dominate portable electronics, electric vehicles, and aerospace applications, valued for their high energy density, lightweight design, and longer cycle life. Industries such as grid storage and material handling shift toward lithium-ion technology, benefiting from faster charging times and reduced maintenance compared to lead-acid counterparts.

Lead-Acid Battery vs Lithium-Ion Battery Infographic

materialdif.com

materialdif.com