Lead shot consists of small, spherical pellets commonly used in shotgun shells for hunting and shooting sports, offering widespread impact and easier dispersion. Lead rods are solid cylindrical forms primarily used in industrial applications such as fishing weights, radiation shielding, and machining processes, providing durability and precise shaping. Choosing between lead shot and lead rods depends on the specific use case, with lead shot preferred for ammunition and lead rods favored for manufacturing and structural purposes.

Table of Comparison

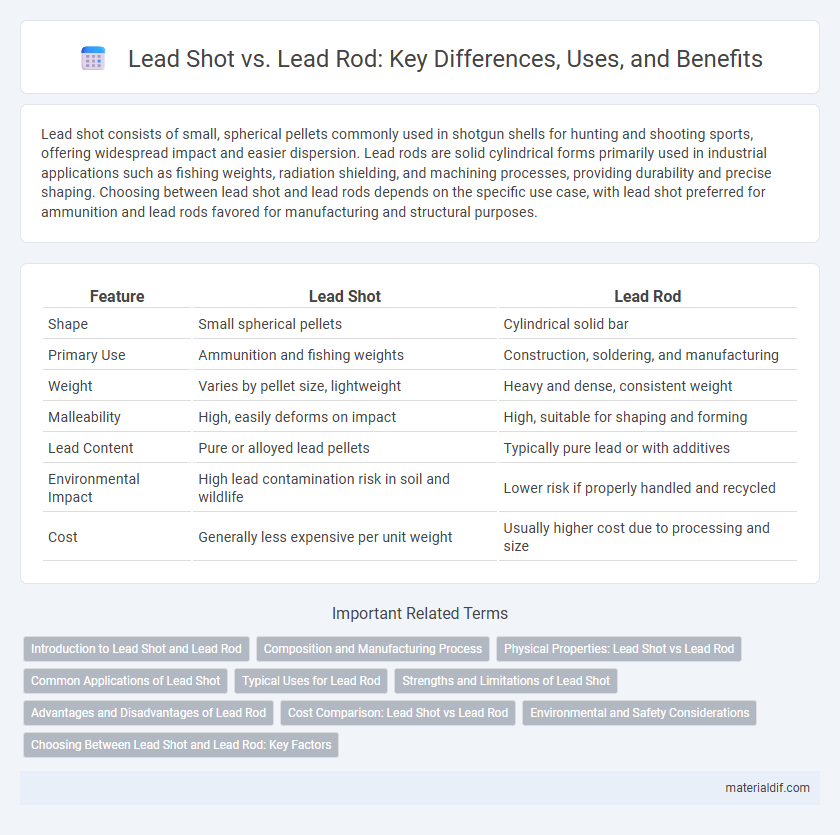

| Feature | Lead Shot | Lead Rod |

|---|---|---|

| Shape | Small spherical pellets | Cylindrical solid bar |

| Primary Use | Ammunition and fishing weights | Construction, soldering, and manufacturing |

| Weight | Varies by pellet size, lightweight | Heavy and dense, consistent weight |

| Malleability | High, easily deforms on impact | High, suitable for shaping and forming |

| Lead Content | Pure or alloyed lead pellets | Typically pure lead or with additives |

| Environmental Impact | High lead contamination risk in soil and wildlife | Lower risk if properly handled and recycled |

| Cost | Generally less expensive per unit weight | Usually higher cost due to processing and size |

Introduction to Lead Shot and Lead Rod

Lead shot consists of small, spherical pellets typically used in shotgun shells for hunting and shooting sports, while lead rods are solid, cylindrical bars commonly used in industrial applications such as radiation shielding and machining. Lead shot offers versatility in distribution and impact surface area, whereas lead rods provide structural stability and are easier to shape or machine for specific projects. Both forms leverage lead's density and malleability, making them essential for different specialized purposes.

Composition and Manufacturing Process

Lead shot consists of small spherical pellets primarily manufactured through a drop method where molten lead is poured from a height, allowing it to form spherical shapes upon cooling, typically composed of pure lead or lead alloyed with small amounts of antimony for hardness. Lead rods are elongated cylindrical bars produced by casting or extrusion processes, often containing higher concentrations of antimony or other metals to enhance mechanical strength and durability. The manufacturing differences impact the microstructure and applications, with shot requiring precise spherical uniformity and rods demanding consistent density and structural integrity.

Physical Properties: Lead Shot vs Lead Rod

Lead shot consists of small, spherical pellets with high density and excellent malleability, making it ideal for applications requiring uniform dispersion and shock absorption. Lead rods exhibit a solid, elongated form with greater tensile strength and rigidity, suitable for structural uses and precise machining. The physical properties such as shape, surface area, and mechanical strength differentiate lead shot's flexibility from lead rod's stability and durability.

Common Applications of Lead Shot

Lead shot is commonly used in shotgun ammunition for hunting birds and small game due to its dense and malleable properties, which allow for effective spread and impact. It is also applied in ballast for balancing aircraft and racing cars, providing weight without sacrificing space. In contrast, lead rods are primarily utilized in industrial settings for manufacturing and electrical grounding because of their solid form and conductivity.

Typical Uses for Lead Rod

Lead rods are commonly used in construction, plumbing, and electrical applications due to their malleability and corrosion resistance. Unlike lead shot, which is primarily employed in ammunition and ballast, lead rods are ideal for creating seals, flashing, and radiation shielding. Their versatility makes them essential in custom fabrication and industrial settings.

Strengths and Limitations of Lead Shot

Lead shot offers versatility for shotgun ammunition with its spherical shape enabling widespread impact, ideal for hunting small game and birds. Its strength lies in ease of loading and consistent spread patterns, while limitations include lower penetration compared to lead rods and potential deformation upon impact. Lead rods excel in applications requiring solid mass and structural integrity but lack the dispersion advantage of lead shot.

Advantages and Disadvantages of Lead Rod

Lead rods offer superior precision and ease of handling compared to lead shot, making them ideal for applications requiring controlled shaping and minimal waste. Their solid form reduces contamination risks and improves melting efficiency, though they tend to be less versatile for rapid dispersion tasks and can be more expensive to transport due to their density. The disadvantage lies in limited adaptability for uses demanding quick spreading or layering, where lead shot's granular nature excels.

Cost Comparison: Lead Shot vs Lead Rod

Lead shot generally costs less per pound compared to lead rods due to its granulated form and ease of mass production. Lead rods require more processing and shaping, which increases manufacturing expenses and retail prices. When budgeting for projects involving lead, choosing lead shot often proves more economical, especially for applications needing smaller quantities or varied sizes.

Environmental and Safety Considerations

Lead shot poses significant environmental hazards due to its propensity to disperse in water bodies and soils, contributing to wildlife poisoning and ecosystem contamination. Lead rods, often used in industrial applications, present lower immediate dispersal risks but require strict handling protocols to prevent lead dust and fume exposure during machining or welding. Proper storage, disposal, and use of protective equipment are critical in minimizing lead's toxic impact on human health and the environment.

Choosing Between Lead Shot and Lead Rod: Key Factors

Choosing between lead shot and lead rod depends on application requirements such as shape, weight distribution, and ease of handling; lead shot offers versatility and uniformity for shotguns and ballast, while lead rods provide solid, customizable material for casting and structural use. Consider factors like size, melting point, and density to determine which form best suits manufacturing or construction needs. Cost-effectiveness and availability also influence the decision, with lead shot generally being more affordable for mass dispersal and lead rods favored for precision work.

Lead shot vs Lead rod Infographic

materialdif.com

materialdif.com