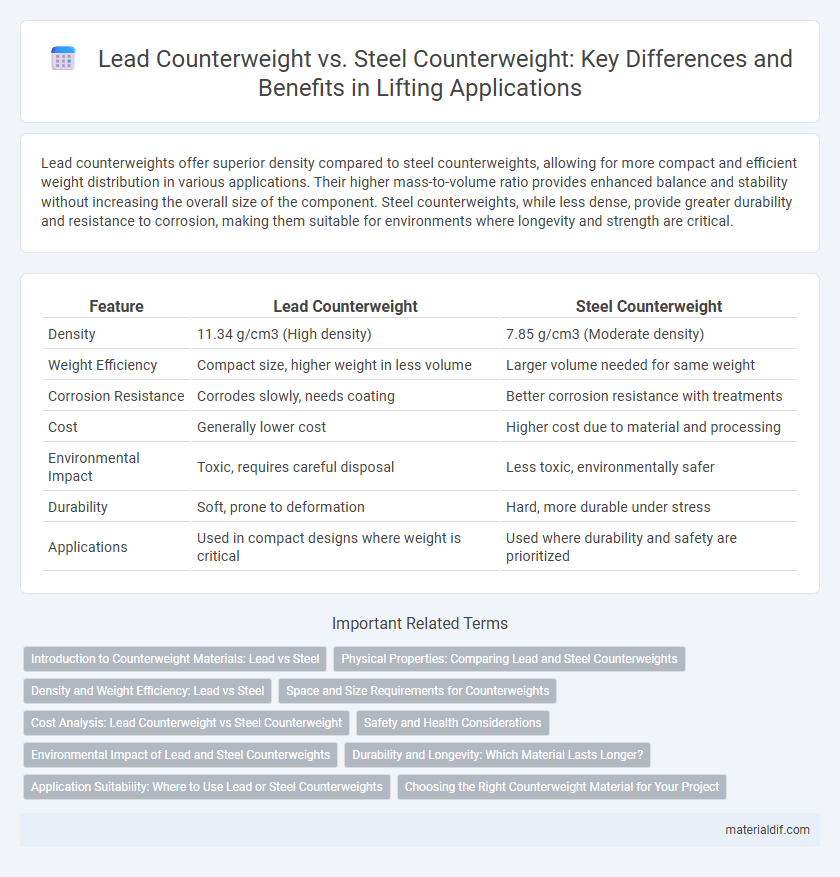

Lead counterweights offer superior density compared to steel counterweights, allowing for more compact and efficient weight distribution in various applications. Their higher mass-to-volume ratio provides enhanced balance and stability without increasing the overall size of the component. Steel counterweights, while less dense, provide greater durability and resistance to corrosion, making them suitable for environments where longevity and strength are critical.

Table of Comparison

| Feature | Lead Counterweight | Steel Counterweight |

|---|---|---|

| Density | 11.34 g/cm3 (High density) | 7.85 g/cm3 (Moderate density) |

| Weight Efficiency | Compact size, higher weight in less volume | Larger volume needed for same weight |

| Corrosion Resistance | Corrodes slowly, needs coating | Better corrosion resistance with treatments |

| Cost | Generally lower cost | Higher cost due to material and processing |

| Environmental Impact | Toxic, requires careful disposal | Less toxic, environmentally safer |

| Durability | Soft, prone to deformation | Hard, more durable under stress |

| Applications | Used in compact designs where weight is critical | Used where durability and safety are prioritized |

Introduction to Counterweight Materials: Lead vs Steel

Lead counterweights offer higher density, allowing for smaller, more compact designs compared to steel, which is less dense but provides greater structural strength. Steel counterweights are favored in applications requiring enhanced durability and resistance to mechanical stress, despite their larger size and weight. The choice between lead and steel counterweights depends on factors such as space constraints, load requirements, and environmental considerations, with lead excelling in space-saving and steel in robust applications.

Physical Properties: Comparing Lead and Steel Counterweights

Lead counterweights have a density of approximately 11.34 g/cm3, making them significantly heavier and more compact than steel counterweights, which have a density near 7.85 g/cm3. This higher density allows lead counterweights to occupy less space while providing the same mass, benefiting applications with size constraints. Steel counterweights, while larger for the same weight, offer better structural strength and corrosion resistance, influencing the choice based on mechanical demands and environmental exposure.

Density and Weight Efficiency: Lead vs Steel

Lead counterweights exhibit significantly higher density, around 11.34 g/cm3, compared to steel's density of approximately 7.85 g/cm3, enabling lead to provide greater weight efficiency in compact volumes. This density advantage allows lead counterweights to achieve the necessary mass with less space, critical in applications where size constraints matter, such as in elevators or machinery balancing. Although steel offers superior strength and durability, lead's weight efficiency remains unmatched for maximizing mass in limited volumes.

Space and Size Requirements for Counterweights

Lead counterweights provide higher density, allowing for smaller volume and more compact designs in space-constrained applications. Steel counterweights require significantly larger size to achieve the same mass, impacting spatial efficiency and installation flexibility. Choosing lead reduces overall counterweight footprint, optimizing space utilization in machinery and structural systems.

Cost Analysis: Lead Counterweight vs Steel Counterweight

Lead counterweights typically offer a lower cost per unit weight compared to steel due to lead's higher density, which reduces the overall volume and material required for the same counterbalance. Steel counterweights may incur higher manufacturing and transportation costs because of their bulkier size and additional fabrication processes. An in-depth cost analysis reveals lead's advantage in minimizing logistics expenses and material usage, despite fluctuations in raw material prices.

Safety and Health Considerations

Lead counterweights offer superior density, allowing for smaller, more compact weights that reduce handling risks compared to bulkier steel counterweights. However, lead poses significant health hazards due to its toxicity, requiring strict safety measures such as protective gloves and ventilation during use and disposal. Steel counterweights, though less dense and larger, present fewer health risks, making them a safer option in environments where exposure to toxic materials cannot be effectively controlled.

Environmental Impact of Lead and Steel Counterweights

Lead counterweights pose significant environmental risks due to lead's toxicity and persistence, leading to soil and water contamination during manufacturing, use, and disposal. Steel counterweights, while requiring more energy to produce, offer greater recyclability and lower long-term environmental hazards, reducing ecological impact. Choosing steel over lead supports sustainable practices by minimizing heavy metal pollution and encouraging circular material use.

Durability and Longevity: Which Material Lasts Longer?

Lead counterweights offer superior durability due to their high density and resistance to corrosion, ensuring a longer lifespan in harsh environments. Steel counterweights, while strong and structurally rigid, are prone to rust and require protective coatings to prevent degradation over time. In terms of longevity, lead inherently maintains its mass and integrity longer without extensive maintenance compared to steel, making it the preferred choice for applications demanding sustained performance.

Application Suitability: Where to Use Lead or Steel Counterweights

Lead counterweights offer high density and corrosion resistance, making them ideal for compact applications in aerospace, automotive, and precision machinery where space and weight efficiency are critical. Steel counterweights provide superior strength and durability at a lower cost, suitable for heavy-duty industrial equipment, construction machinery, and elevator systems requiring robust structural support. Selecting lead or steel counterweights depends on factors such as weight constraints, environmental conditions, and load-bearing requirements in specific applications.

Choosing the Right Counterweight Material for Your Project

Lead counterweights offer high density and excellent vibration damping, making them ideal for compact designs where space is limited. Steel counterweights provide superior durability and corrosion resistance, suitable for outdoor or heavy-duty applications requiring structural strength. Evaluating project-specific needs such as weight requirements, environmental conditions, and budget constraints ensures the optimal choice between lead and steel counterweights.

Lead counterweight vs Steel counterweight Infographic

materialdif.com

materialdif.com