Lead weights offer superior density, providing better casting distance and accuracy for anglers seeking precision. Zinc weights, while less dense, present an environmentally safer alternative with reduced toxicity, making them ideal for eco-conscious fishing practices. Choosing between lead and zinc weights depends on balancing performance needs with environmental impact considerations.

Table of Comparison

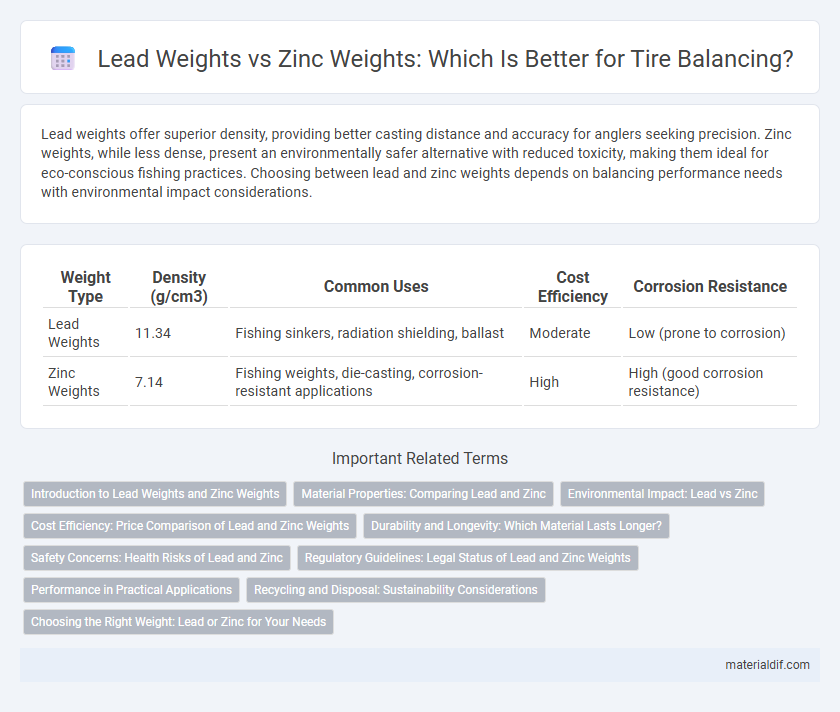

| Weight Type | Density (g/cm3) | Common Uses | Cost Efficiency | Corrosion Resistance |

|---|---|---|---|---|

| Lead Weights | 11.34 | Fishing sinkers, radiation shielding, ballast | Moderate | Low (prone to corrosion) |

| Zinc Weights | 7.14 | Fishing weights, die-casting, corrosion-resistant applications | High | High (good corrosion resistance) |

Introduction to Lead Weights and Zinc Weights

Lead weights offer high density and durability, making them ideal for fishing and diving applications where compact weight is crucial. Zinc weights provide an eco-friendly alternative, as they are non-toxic and corrosion-resistant, suitable for use in environmentally sensitive waters. Both materials vary in weight and cost, influencing buyer decisions based on specific usage requirements and environmental impact.

Material Properties: Comparing Lead and Zinc

Lead weights offer higher density and superior malleability compared to zinc weights, making them ideal for applications requiring compact mass and precision shaping. Zinc weights, while less dense, provide better corrosion resistance and lower toxicity, enhancing safety and durability in various environments. The choice between lead and zinc weights depends on balancing material density with environmental and health considerations.

Environmental Impact: Lead vs Zinc

Lead weights pose significant environmental risks due to their toxicity and persistence in ecosystems, often contaminating water and soil. Zinc weights, while still metal-based, are generally less harmful, exhibiting lower toxicity and better biodegradability compared to lead. Choosing zinc weights mitigates heavy metal pollution and supports safer ecological practices in fishing and industrial applications.

Cost Efficiency: Price Comparison of Lead and Zinc Weights

Lead weights generally offer superior cost efficiency compared to zinc weights due to their lower market price and higher density, which allows for smaller sizes at equivalent weights. Zinc weights tend to be more expensive per pound and require larger volumes to achieve the same mass, impacting shipping and handling costs. Industries focused on budget-sensitive applications often prefer lead for weight solutions because it balances affordability with performance effectively.

Durability and Longevity: Which Material Lasts Longer?

Lead weights offer superior durability and longevity compared to zinc weights due to their higher density and resistance to corrosion. Zinc weights, while more environmentally friendly, tend to degrade faster in marine environments, reducing their lifespan. The intrinsic properties of lead result in longer-lasting performance, making it the preferred choice for applications requiring extended durability.

Safety Concerns: Health Risks of Lead and Zinc

Lead weights pose significant health risks due to lead's toxicity, which can cause neurological damage, especially in children, and chronic exposure may lead to kidney and cardiovascular problems. Zinc weights are considered safer alternatives since zinc is less toxic and poses minimal health hazards under typical handling conditions. Proper precautions such as avoiding ingestion and minimizing dust exposure are essential when handling lead weights to reduce the risk of lead poisoning.

Regulatory Guidelines: Legal Status of Lead and Zinc Weights

Lead weights face strict regulatory restrictions in many countries due to their toxicity and environmental hazards, with bans or limitations under laws such as the EU's REACH Regulation and the US EPA's Lead Renovation Rule. Zinc weights are often considered a safer alternative and are generally exempt from such stringent regulations, allowing broader legal use in fishing and industrial applications. Compliance with regional regulatory guidelines is crucial when selecting weights to avoid legal penalties and ensure environmental safety.

Performance in Practical Applications

Lead weights offer superior density and stability, providing consistent performance in fishing and diving applications where precise weight distribution is crucial. Zinc weights, though less dense, are environmentally friendly and resist corrosion in saltwater, making them ideal for prolonged use in marine conditions. Practical performance hinges on balancing lead's weight efficiency against zinc's durability and environmental impact.

Recycling and Disposal: Sustainability Considerations

Lead weights offer high recyclability with established recycling infrastructure, minimizing environmental impact through efficient recovery processes, whereas zinc weights, while less toxic, face challenges due to lower recycling rates and more limited facilities. Disposal of lead weights requires careful handling to prevent soil and water contamination from lead leaching, making specialized recycling essential for sustainability. Zinc's lower toxicity reduces disposal hazards but emphasizes the need for improved recycling technologies to optimize resource recovery and environmental benefits.

Choosing the Right Weight: Lead or Zinc for Your Needs

Lead weights offer superior density and durability, ideal for deep-sea fishing and heavy-duty applications, while zinc weights provide an eco-friendly alternative with corrosion resistance suitable for freshwater environments. Selecting the right weight depends on balancing performance needs with environmental impact, as lead poses toxicity risks to aquatic life. Fishermen seeking sustainable options should consider zinc weights without compromising effective ballast or sink rate.

Lead weights vs Zinc weights Infographic

materialdif.com

materialdif.com