Lead tape offers superior weight and flexibility for precise balancing in applications like fishing and sports equipment, while copper tape is favored for its excellent electrical conductivity and corrosion resistance in electronic and craft projects. Lead tape is denser, providing more weight in a smaller size, making it ideal for fine-tuning weight distribution without bulk. Copper tape's adhesive properties and durability make it suitable for grounding, EMI shielding, and decorative purposes where conductivity and longevity are essential.

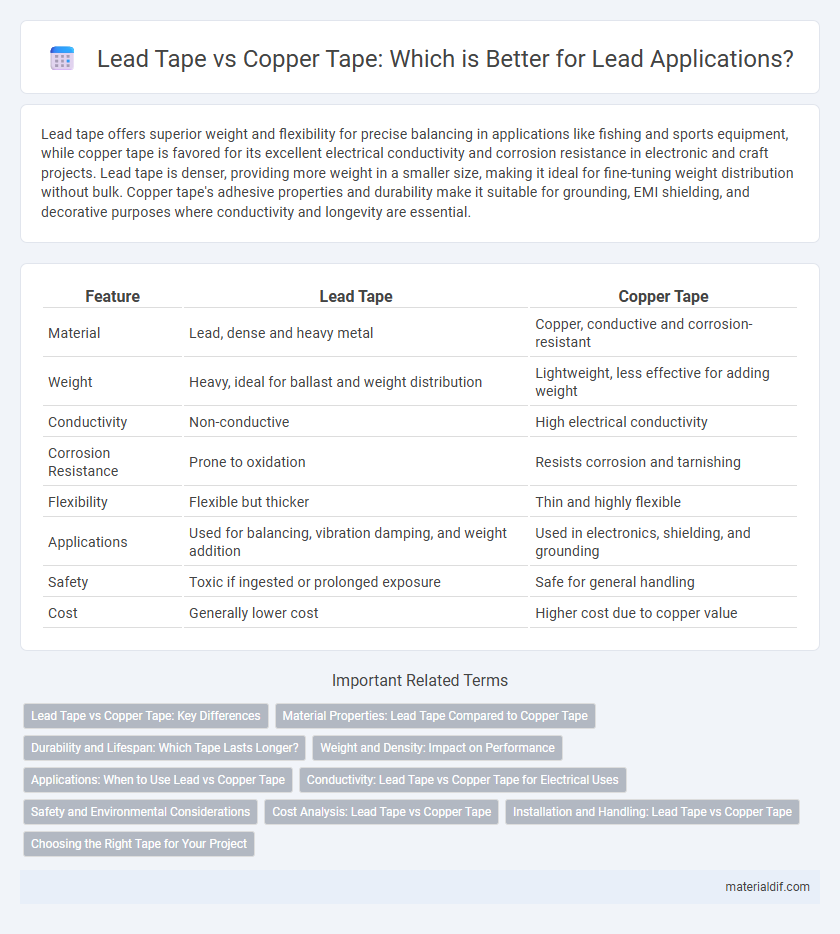

Table of Comparison

| Feature | Lead Tape | Copper Tape |

|---|---|---|

| Material | Lead, dense and heavy metal | Copper, conductive and corrosion-resistant |

| Weight | Heavy, ideal for ballast and weight distribution | Lightweight, less effective for adding weight |

| Conductivity | Non-conductive | High electrical conductivity |

| Corrosion Resistance | Prone to oxidation | Resists corrosion and tarnishing |

| Flexibility | Flexible but thicker | Thin and highly flexible |

| Applications | Used for balancing, vibration damping, and weight addition | Used in electronics, shielding, and grounding |

| Safety | Toxic if ingested or prolonged exposure | Safe for general handling |

| Cost | Generally lower cost | Higher cost due to copper value |

Lead Tape vs Copper Tape: Key Differences

Lead tape offers high density and excellent weight distribution, making it ideal for balancing applications in sports like golf and fishing. Copper tape provides superior conductivity and corrosion resistance, frequently used in electrical and shielding projects. The key differences lie in lead tape's weight-enhancing properties versus copper tape's electrical and anti-corrosive advantages.

Material Properties: Lead Tape Compared to Copper Tape

Lead tape offers higher density and greater mass per unit length compared to copper tape, making it ideal for applications requiring added weight in compact forms. Its malleability ensures easy conformity to irregular surfaces without cracking, whereas copper tape emphasizes electrical conductivity and corrosion resistance. Lead tape's softness and lower thermal conductivity differ significantly from copper's durability and heat dissipation properties, influencing their suitability for specific industrial or crafts uses.

Durability and Lifespan: Which Tape Lasts Longer?

Lead tape offers superior durability and a longer lifespan compared to copper tape due to its dense, corrosion-resistant properties that withstand environmental wear and tear. Copper tape tends to oxidize and degrade faster when exposed to moisture and air, reducing its effective lifespan. For applications demanding long-term performance, lead tape remains the preferred choice for consistent durability.

Weight and Density: Impact on Performance

Lead tape offers higher density at approximately 11.34 g/cm3, providing greater weight per unit volume compared to copper tape, which has a density around 8.96 g/cm3. This increased density allows lead tape to deliver better balance and stability in applications such as sports equipment and musical instruments, improving performance by lowering the center of gravity. Copper tape, being lighter, is preferred where weight reduction and flexibility are priorities despite its lower mass contribution.

Applications: When to Use Lead vs Copper Tape

Lead tape offers excellent weight distribution for sports equipment like golf clubs and fishing rods, enhancing balance and stability, while copper tape excels in electrical applications due to its superior conductivity and corrosion resistance. Use lead tape to adjust weight without volume increase in precision sports tuning and vibration damping, whereas copper tape is ideal for electromagnetic shielding, grounding, and electrical repairs. Selecting the appropriate tape depends on whether the application prioritizes weight modification or electrical performance.

Conductivity: Lead Tape vs Copper Tape for Electrical Uses

Copper tape offers significantly higher electrical conductivity compared to lead tape, making it the preferred choice for efficient current flow in electrical applications. Lead tape, with its lower conductivity, is typically used for shielding or weight purposes rather than as a conductor. The superior conductivity of copper tape ensures minimal resistance and enhanced performance in circuits and grounding systems.

Safety and Environmental Considerations

Lead tape poses significant health risks due to lead's toxicity, making it hazardous during handling and disposal. Copper tape offers a safer alternative, as copper is less toxic and more environmentally friendly, with easier recyclability and lower ecological impact. Choosing copper tape reduces potential lead contamination in homes and ecosystems, promoting safer use and disposal.

Cost Analysis: Lead Tape vs Copper Tape

Lead tape generally offers a lower initial cost compared to copper tape, making it more budget-friendly for applications requiring weight addition or vibration damping. Copper tape, while more expensive upfront, provides superior conductivity and corrosion resistance, potentially reducing long-term maintenance expenses. Cost analysis should consider both material price and performance benefits based on specific project requirements.

Installation and Handling: Lead Tape vs Copper Tape

Lead tape offers easier installation due to its malleability and adhesive backing, conforming smoothly to curved surfaces without requiring special tools. Copper tape, while also adhesive, demands careful handling to avoid kinks and requires grounding in some applications to prevent electrical interference. Both tapes are effective but differ in flexibility and installation nuance based on project requirements.

Choosing the Right Tape for Your Project

Lead tape offers superior density and flexibility, making it ideal for applications requiring precise weight distribution and vibration dampening. Copper tape excels in electrical conductivity and corrosion resistance, perfect for electrical projects or EMI shielding. Selecting the right tape depends on project requirements such as weight adjustment, electrical insulation, or shielding effectiveness.

Lead tape vs Copper tape Infographic

materialdif.com

materialdif.com